Preparation method of environment-friendly lead-cadmium-free red glass and product prepared by the same

A cadmium red, environment-friendly technology, which is applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of complex melting process and unstable color of antimony red glass, and achieve efficient production and preparation methods Simple and easy to use, promotes the effect of color development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

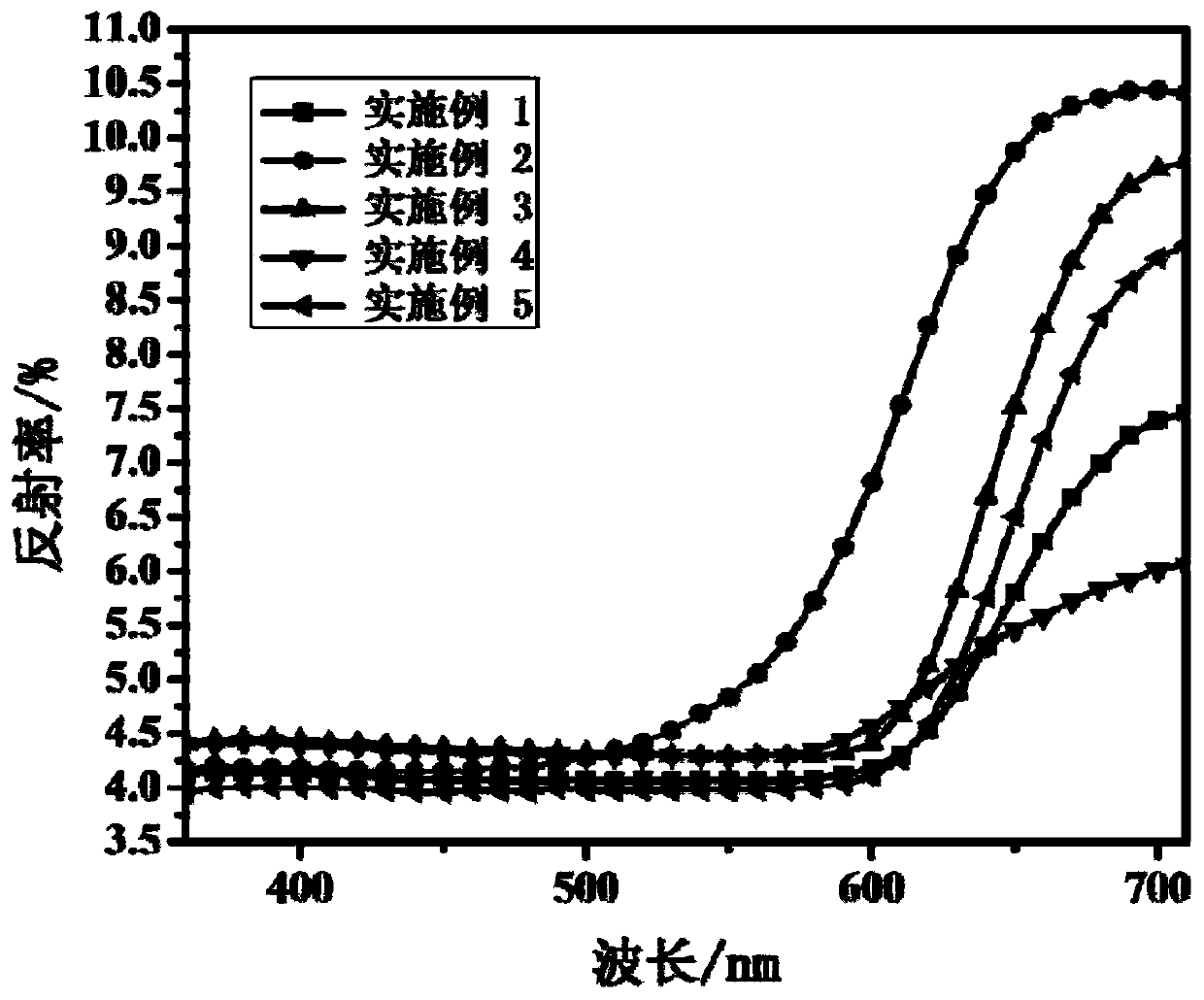

Embodiment 1

[0026] The preparation method of a kind of environment-friendly lead-free cadmium red glass of this embodiment, its steps are as follows:

[0027] (1) Pretreatment of stable colorants

[0028] According to the composition of the stable coloring agent in parts by mass, it is Sb 2 o 3 1.50 parts, 2.63 parts of S, 0.38 parts of C, 0.011 parts of CuO; after mixing the components of the above-mentioned stable colorant evenly, the stable colorant according to the mass ratio: sodium silicate water glass=1:9, mixed with sodium silicate water glass Uniformly form a semi-solid mixture; then place it in a low-temperature oven at 90°C to dry to constant weight, pass through a 200-mesh standard sieve after crushing, and obtain a pretreated stable colorant;

[0029] (2) Preparation of mixed raw materials

[0030] According to the composition of the basic components in parts by mass, it is SiO 2 48.81 parts, Na 2 CO 3 22.72 copies, K 2 CO 3 11.08 parts, CaCO 3 10.84 copies, H 3 BO ...

Embodiment 2

[0037] The preparation method of a kind of environment-friendly lead-free cadmium red glass of this embodiment, its steps are as follows:

[0038] (1) Pretreatment of stable colorants

[0039] According to the composition of the stable coloring agent in parts by mass, it is Sb 2 o 3 2.51 parts, 2.27 parts of S, 0.46 parts of C, and 0.015 parts of CuO; after mixing the components of the above-mentioned stable colorant evenly, the stable colorant according to the mass ratio: sodium silicate water glass=1:11, mixed with sodium silicate water glass Uniformly form a semi-solid mixture; then place it in a low-temperature oven at 130°C and dry it to constant weight, pass through a 200-mesh standard sieve after crushing, and obtain a pretreated stable colorant;

[0040] (2) Preparation of mixed raw materials

[0041] According to the composition of the basic components in parts by mass, it is SiO 2 46.45 parts, Na 2 CO 3 20.61 copies, K 2 CO 3 12.07 parts, CaCO 3 12.56 copies...

Embodiment 3

[0048] The preparation method of a kind of environment-friendly lead-free cadmium red glass of this embodiment, its steps are as follows:

[0049] (1) Pretreatment of stable colorants

[0050] According to the composition of the stable coloring agent in parts by mass, it is Sb 2 o 3 1.77 parts, 1.95 parts of S, 1.07 parts of C, 0.015 parts of CuO; after mixing the components of the above-mentioned stable colorant evenly, the stable colorant according to the mass ratio: sodium silicate water glass=1:13, mixed with sodium silicate water glass Uniformly form a semi-solid mixture; then place it in a low-temperature oven at 150°C to dry to constant weight, pass through a 200-mesh standard sieve after crushing, and obtain a pretreated stable colorant;

[0051] (2) Preparation of mixed raw materials

[0052] According to the composition of the basic components in parts by mass, it is SiO 2 49.22 parts, Na 2 CO 3 24.71 copies, K 2 CO 3 9.67 parts, CaCO 3 8.93 copies, H 3 BO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com