Green flat pitched roof system and construction method

A roofing system and sloping roofing technology, applied in the field of green flat-sloping roofing system and construction, can solve the problems of heavy roof load, complicated laying, multiple structural layers, etc., and achieve the effects of easy laying, solving serious water and soil loss, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

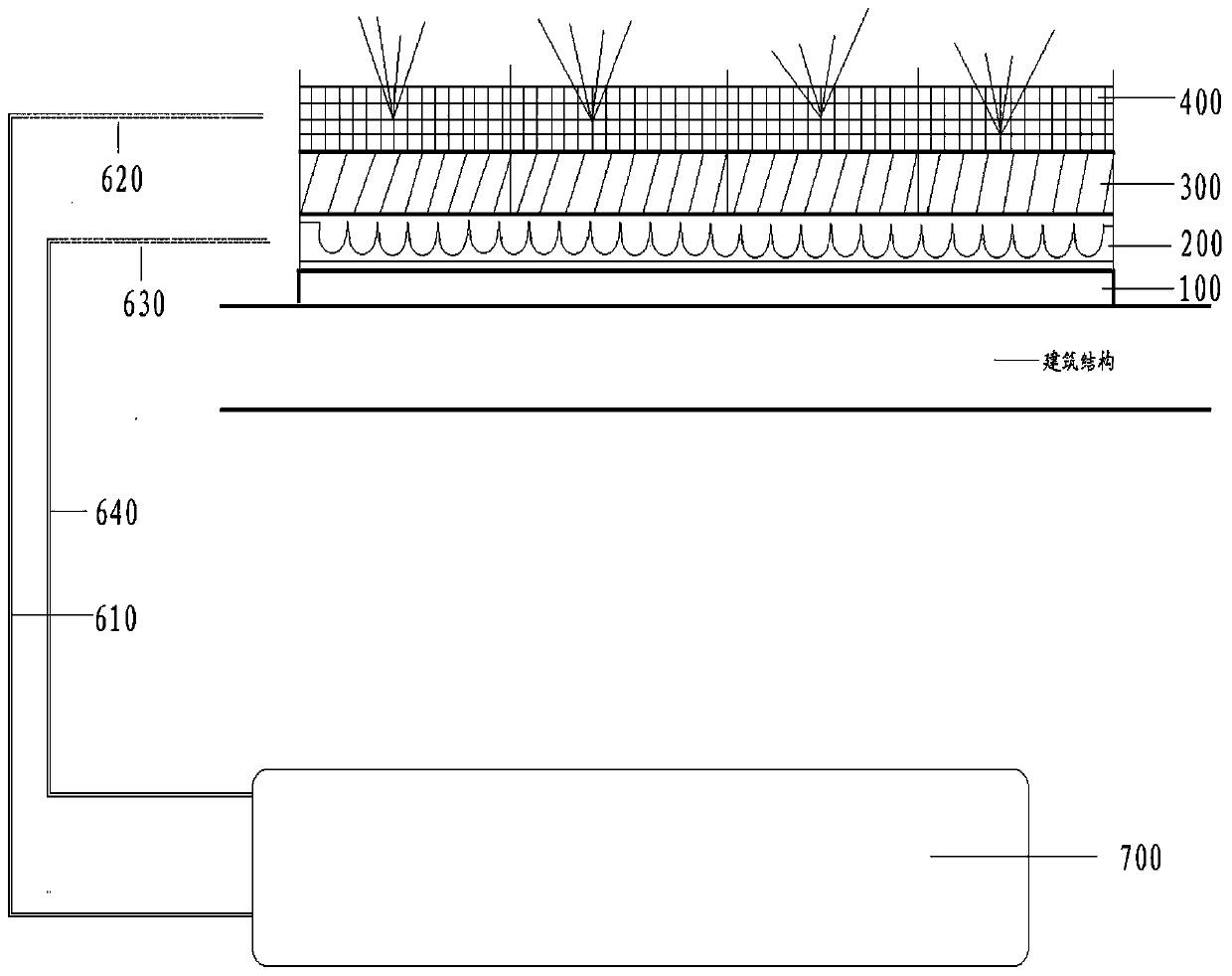

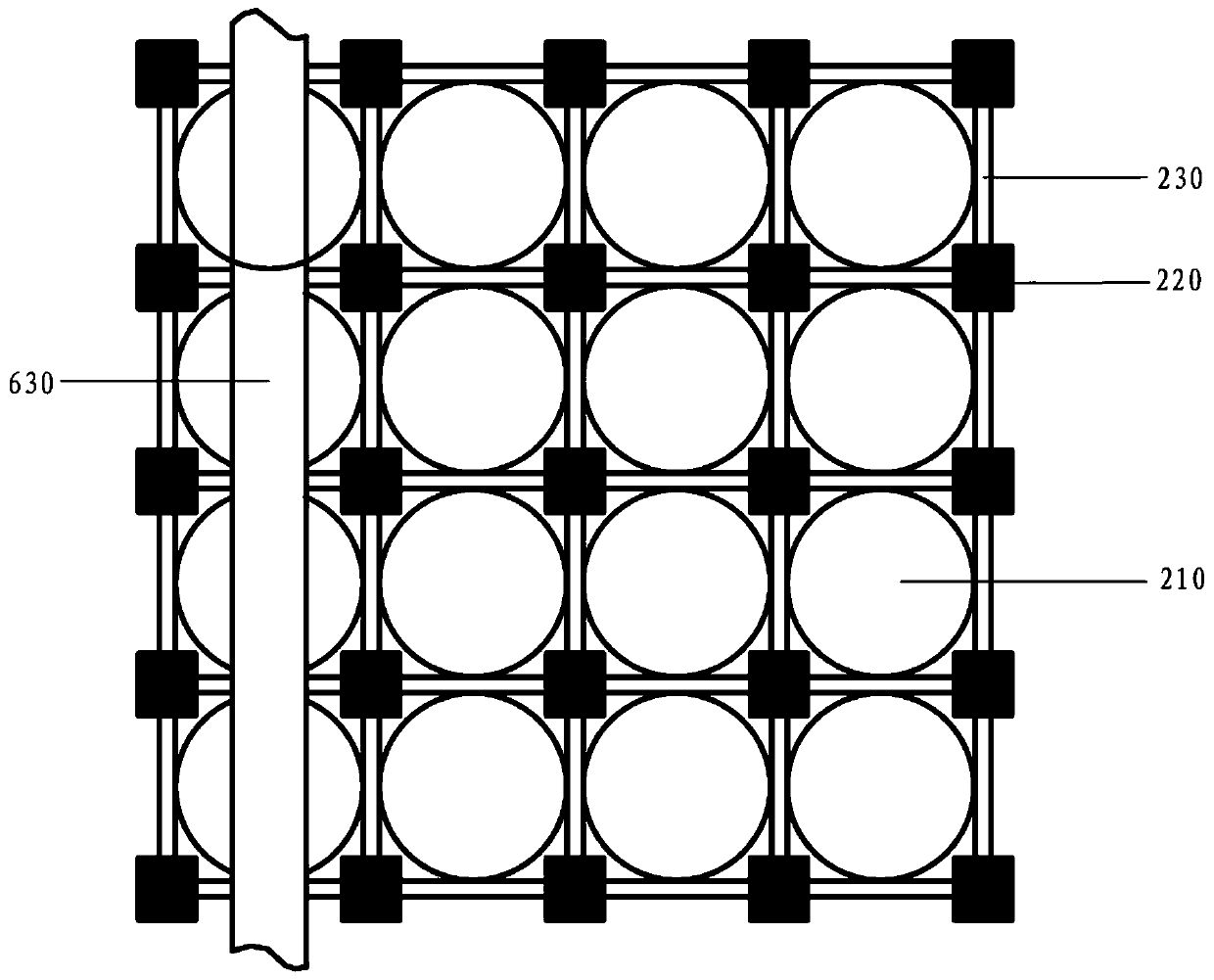

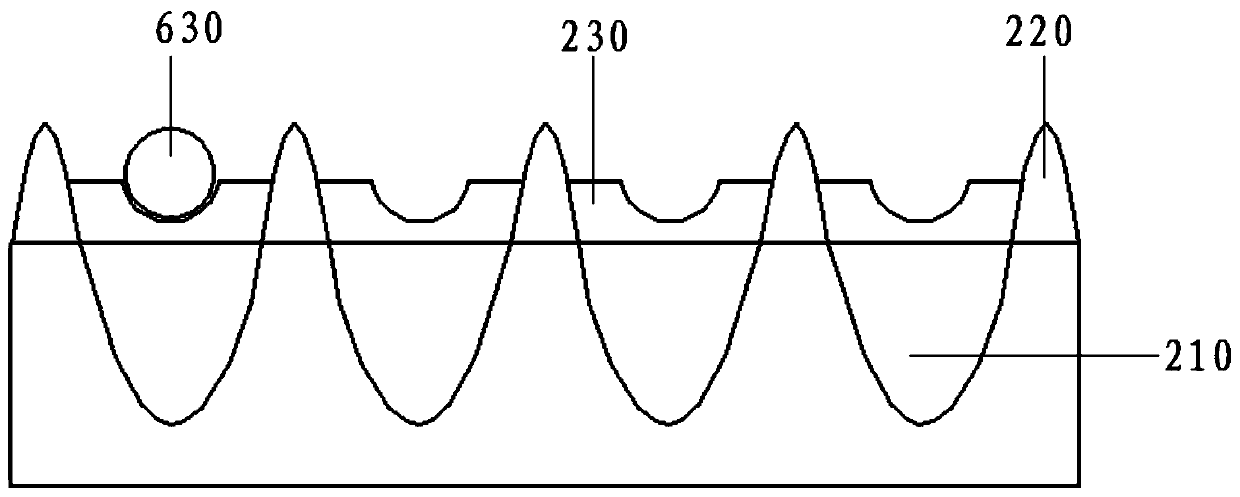

[0157] A green flat slope roof system and its construction method, such as figure 1 Roof system shown. Lay a PET self-adhesive waterproof membrane (thickness 2.0cm, surface resistance 0.06Ω) sprayed with copper coating on the roof, and the membrane is closely connected with the roof; lay a drainage layer made of epoxy resin on the waterproof membrane 200 ,Such as figure 2 and image 3 As shown, the drainage layer 200 is a flat layer with longitudinal recesses 210. The longitudinal recesses 210 are arranged horizontally and vertically in a regular manner, and drainage pipes 630 can be erected in the longitudinal recesses 210 located on a straight line. Between the adjacent longitudinal recesses 210 there is a column body 230 that can form the longitudinal recesses 210 and block the space. The column body 230 is provided with a groove for placing the drain pipe 630 . The height of the drainage layer is 3.0 cm, the depth of the longitudinal recess 210 is 2.5 cm, and the heigh...

Embodiment 2

[0162] A method for constructing a green flat-slope roof system, used for constructing such as figure 1 Roof system shown. This roofing system is the same as in Embodiment 1, the only difference being that about 1×10 8 CFU / g phosphorus accumulating bacteria, 2×10 8 CFU / g denitrifying bacteria and 2×10 8 CFU / g nitrifying bacteria.

Embodiment 3

[0164] A construction method of a green slope roof system, used to construct such as figure 1 Roof system shown. The roofing system is the same as that in Embodiment 1, except that the volume ratio of activated carbon, zeolite and bentonite in the water filter layer 300 is 1:8:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com