High-temperature and high-pressure visual seepage experimental device and method for real sandstone

A high-temperature, high-pressure, experimental device technology, applied in the field of seepage experiments, can solve the problems of unrealistic models, limited experimental temperature, unrealistic, etc., and achieve the effects of safety and environmental protection efficiency, wide application range, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

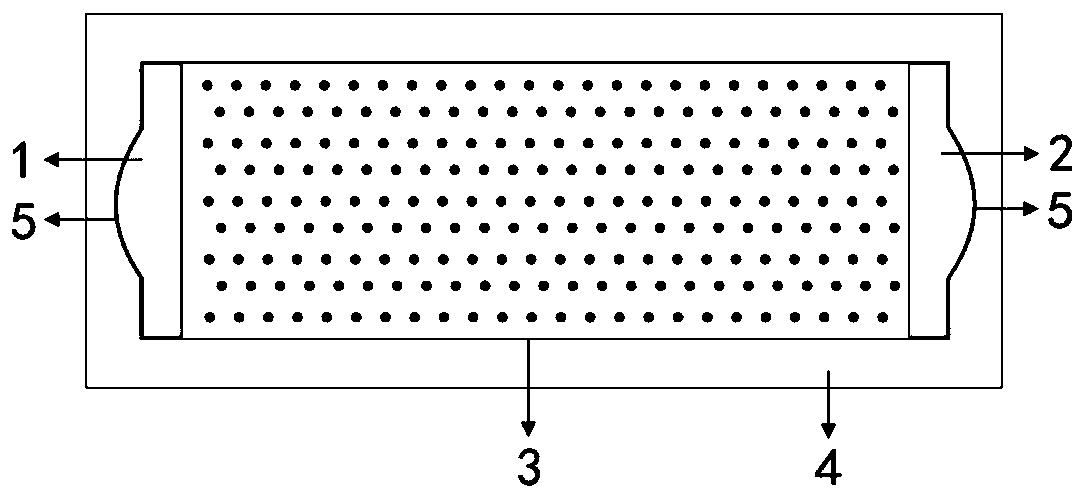

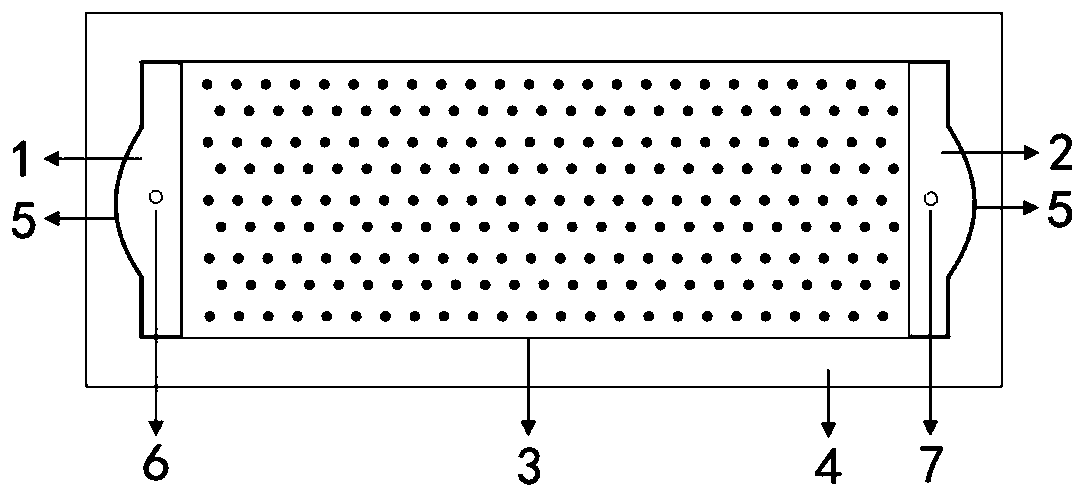

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0048] The real sandstone high temperature and high pressure microscopic visualization model in the present invention is also called a real sandstone model.

[0049] The present invention comprises the following steps:

[0050] 1. To make a real sandstone high temperature and high pressure microscopic visualization model, the steps are as follows:

[0051] 1) Prepare rock slices

[0052] First, select the core samples taken from the underground target layer used in the experiment, and cut the samples into a nearly cuboid shape. The length of the rock slice should be greater than 70mm, the width greater than 30mm, and the thickness should be more than 3mm. Put the sample into the extractor, so that the crude oil in the pore throat of the core is extracted by the organic solvent. After the extraction, the core samples were placed in a drying oven for drying for late...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com