Solid electrolyte and all-solid-state battery

A solid electrolyte and micro-quantity technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems affecting the quality of ceramic sheets, a large number of pores, shrinkage of ceramic sheets, and internal grain growth, etc., to improve and inhibit lithium dendrites Penetrating properties, high density, and stable cubic phase effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

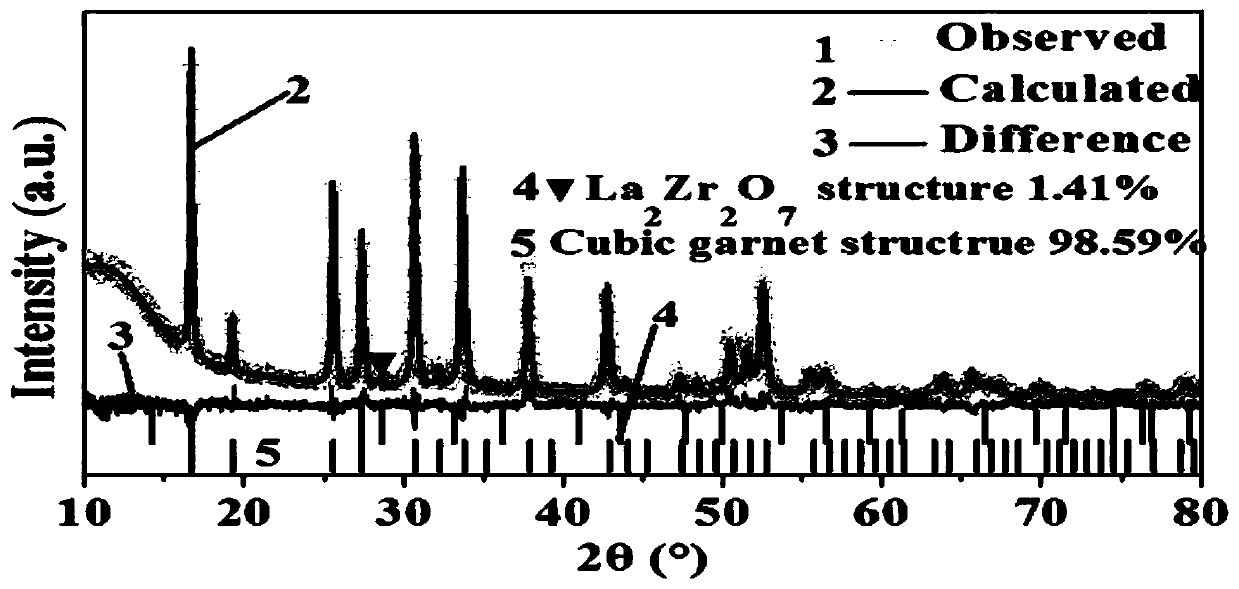

[0039] Will Li 2 O, ZrO 2 , La 2 o 3 、WO 3 , CaO is proportioned according to the stoichiometric ratio Li:La:Ca:Zr:W=6.7:2.8:0.2:1.75:0.25. Before ball milling, the La 2 o 3 Dry at 900°C for 24h, Li 2 The excess of O is 5% to compensate for the loss of lithium during sintering. The raw materials were weighed and placed in a zirconia ball mill jar, and wet ball milled with absolute ethanol as the medium at a milling speed of 200 rpm for 15 hours. Dry the slurry to obtain a uniform powder, and then pre-fire the mixed powder at 900°C for 8h at a heating rate of 1°C / min to obtain 1.41% La 2 Zr 2 o 7 Solid electrolyte powder. In order to obtain a solid electrolyte with higher activity, the solid electrolyte powder is ball milled again. The process is the same as the above ball milling process, and the powder with a smaller particle size is obtained for tableting, and the powder is buried for sintering. The actual density of the solid electrolyte ceramic sheet is measure...

Embodiment 2

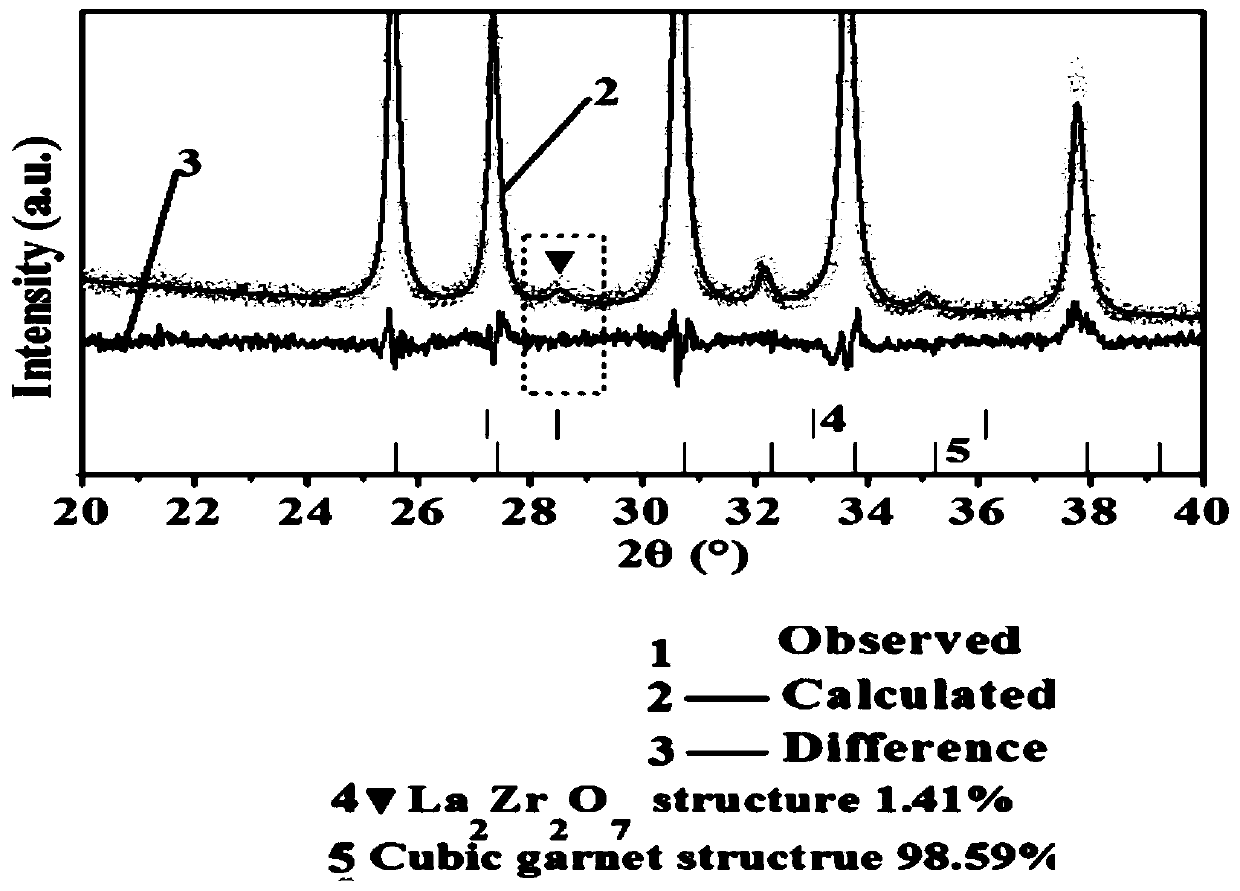

[0049] Will Li 2 O, ZrO 2 , La 2 o 3 、WO 3 , CaO is proportioned according to the stoichiometric ratio Li:La:Ca:Zr:W=6.6:2.9:0.1:1.75:0.25. Before ball milling, the La 2 o 3 Dry at 900°C for 24h, Li 2 The excess of O is 5% to compensate for the loss of lithium during sintering. The raw materials were weighed and placed in a zirconia ball mill jar, and wet ball milled with absolute ethanol as the medium at a milling speed of 200 rpm for 15 hours. Dry the slurry to obtain a uniformly mixed powder, and then pre-fire the mixed powder at 900°C for 8 hours at a heating rate of 1°C / min to obtain a trace La 2 Zr 2 o 7 Structured solid electrolyte powder. In order to obtain a solid electrolyte with higher activity, the solid electrolyte powder is ball milled again, and the process is the same as the above ball mill process to obtain a solid electrolyte powder with a smaller particle size. Image 6 It shows that the La-containing 2 Zr 2 o 7 Structure of the garnet-type so...

Embodiment 3

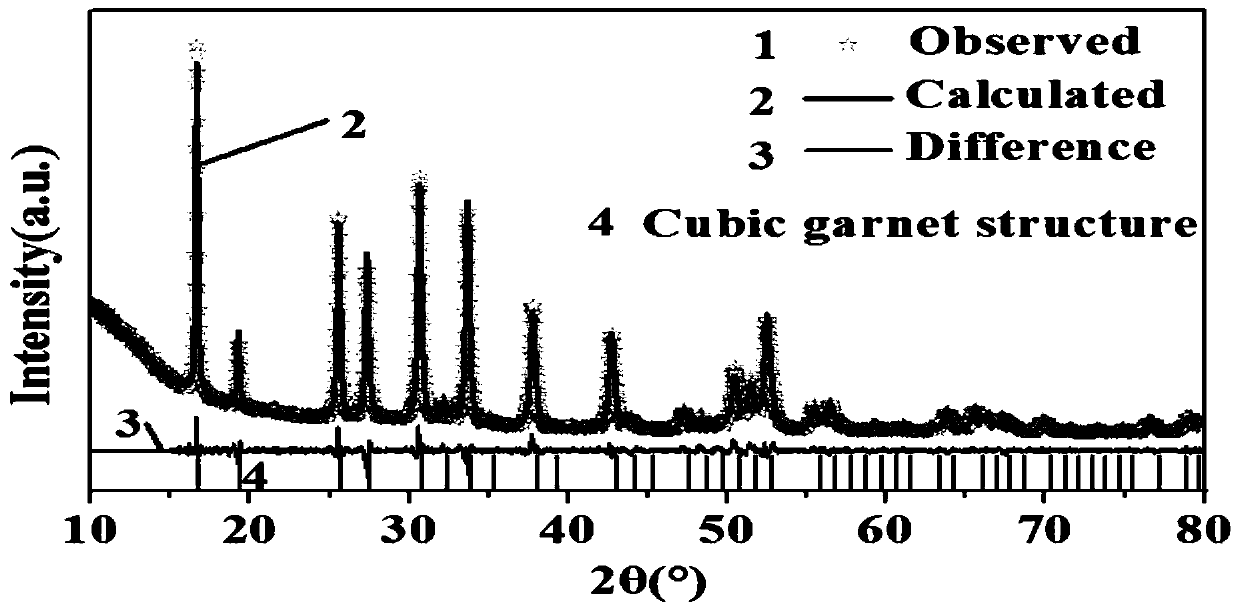

[0051] Will Li 2 O, ZrO 2 , La 2 o 3 、WO 3 , CaO is proportioned according to the stoichiometric ratio Li:La:Ca:Zr:W=6.6:2.9:0.1:1.75:0.25. Before ball milling, La 2 o 3 Dry at 900°C for 24h, Li 2 The excess of O is 5% to compensate for the loss of lithium during sintering. The raw materials were weighed and placed in a zirconia ball mill jar, and wet ball milled with absolute ethanol as the medium at a milling speed of 200 rpm for 15 hours. Dry the slurry to obtain a uniformly mixed powder, and then pre-fire the mixed powder at 900°C for 10h at a heating rate of 1°C / min to obtain a trace La 2 Zr 2 o 7 Structured solid electrolyte powder. In order to obtain a solid electrolyte with higher activity, the solid electrolyte powder is ball milled again, and the process is the same as the above ball milling process to obtain a solid electrolyte powder with a smaller particle size.

[0052] Figure 7 It shows that the La-containing 2 Zr 2 o 7 Structure of the garnet-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com