Design method of kneecap prosthesis

A patella prosthesis and design method technology, applied in the direction of elbow joints, joint implants, knee joints, etc., to meet individual needs, facilitate recovery, and facilitate reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] A kind of design method of patella prosthesis of the present invention, comprises the following steps:

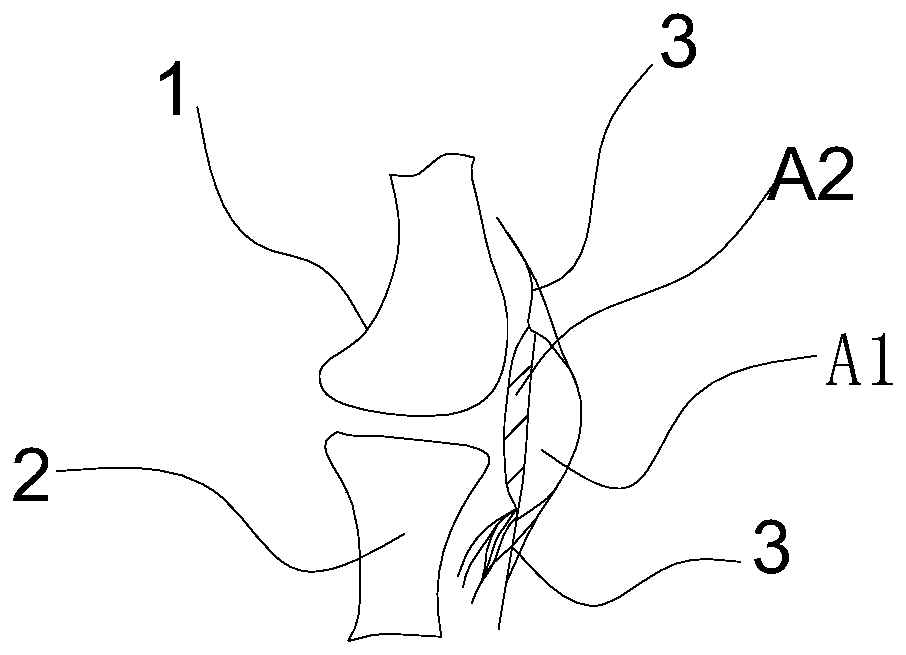

[0028] 1) Use CT or MRI to obtain high-precision three-dimensional raw data of the patient's knee joint, and use reverse engineering methods to establish a three-dimensional model of the patella;

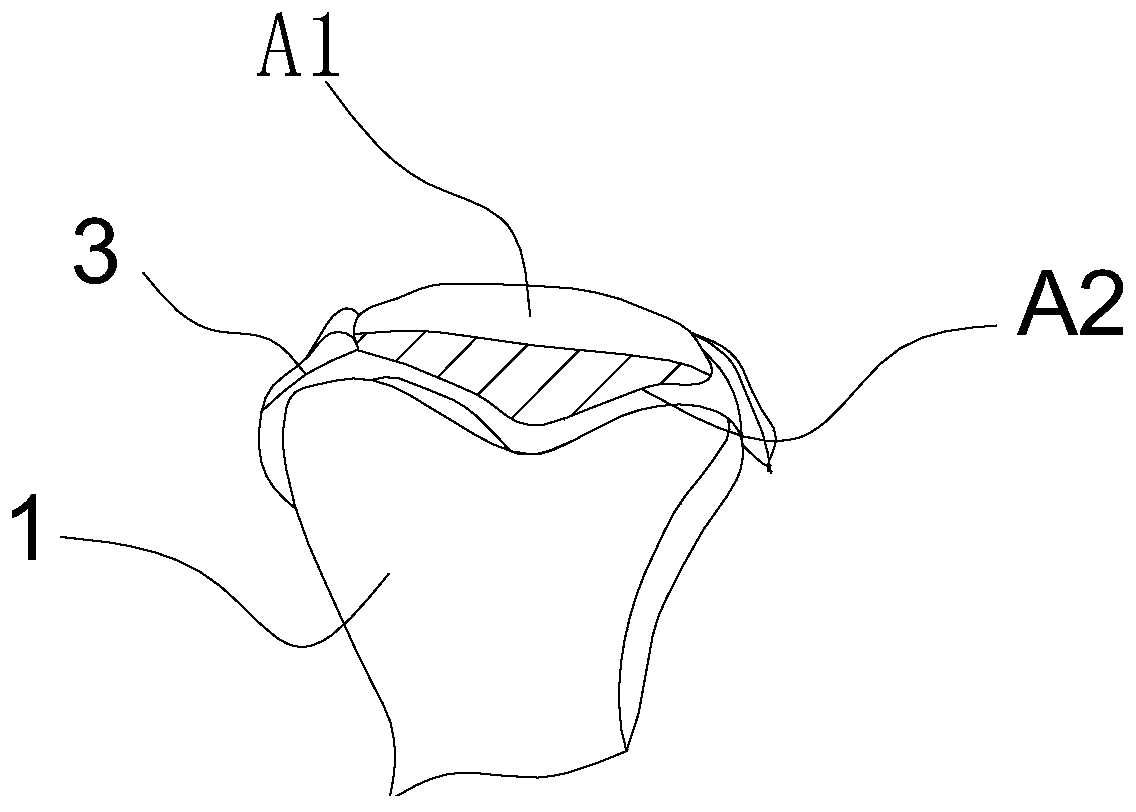

[0029] 2) Establish the cutting plane of the three-dimensional model of the patella through the feature points of the patella, namely the upper pole, the lower pole, the connection point of the lateral retinaculum, and the connection point of the medial retinaculum;

[0030] 3) Using the cutting surface to cut the three-dimensional model of the patella to obtain the three-dimensional model of the prosthesis and the patella retention zone;

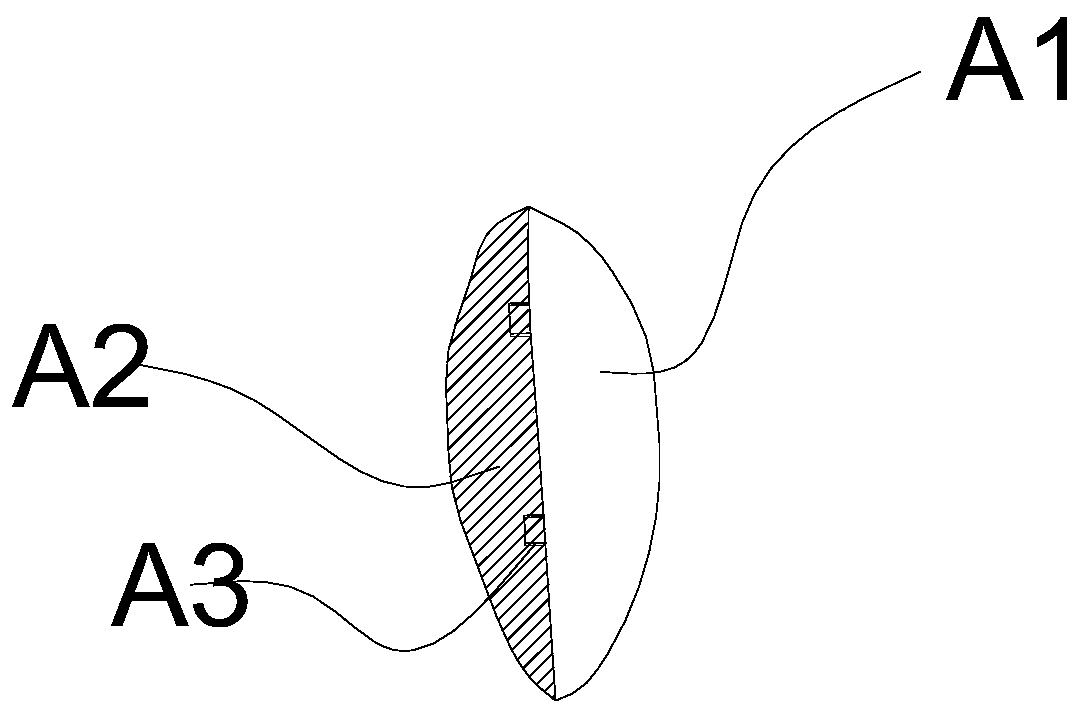

[0031] 4) Based on the three-dimensional model, a protrusion is set on the cutting plane, and at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com