Method for separating ethylene diamine and water azeotrope

An ethylenediamine and water azeotrope technology, applied in the purification/separation of amino compounds, chemical industry, climate sustainability, etc., can solve the problems of dehydrating agent pollution, high energy consumption, inability to perform heat recovery, etc., and reduce energy consumption. , the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

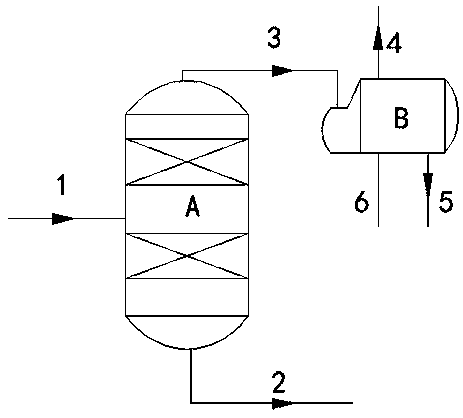

[0024] Embodiment 1 A kind of method of separating ethylenediamine and water azeotrope

[0025] The ethylenediamine and water azeotrope are introduced into the pressurized rectification column A, the operating pressure is controlled at 0.95Mpa, the temperature at the bottom of the column is controlled at 210°C, and the temperature at the top of the column is controlled at 195°C. Ethylenediamine is extracted; the reflux ratio is 14~16; the purity of the water distilled from the top of the tower is 99.6%, and the purity of the ethylenediamine extracted from the bottom of the tower is 99.8%.

[0026] The ethylenediamine and water azeotrope: water 20wt%, ethylenediamine 75%~79wt%, organic amine mixture 1%~5%, the components of the organic amine mixture include diethylenetriamine, aminopiperazine, Hydroxyethylethylenediamine.

[0027] The water evaporated from the top of the tower is introduced into the waste heat recovery device B. When it is introduced, the temperature of the wa...

Embodiment 2

[0028] Embodiment 2 A kind of method of separating ethylenediamine and water azeotrope

[0029] The ethylenediamine and water azeotrope are introduced into the pressurized rectification column A, the operating pressure is controlled at 0.80Mpa, the temperature at the bottom of the tower is controlled at 200°C, and the temperature at the top of the tower is controlled at 185°C. Ethylenediamine is extracted; the reflux ratio is 7~11; the purity of the water distilled from the top of the tower is 99.7%, and the purity of the ethylenediamine extracted from the bottom of the tower is 99.7%.

[0030] The ethylenediamine and water azeotrope: water 20wt%, ethylenediamine 75%~79wt%, organic amine mixture 1%~5%, the components of the organic amine mixture include diethylenetriamine, aminopiperazine, Hydroxyethylethylenediamine.

[0031] The water steamed from the top of the tower is introduced into the waste heat recovery device B. When it is introduced, the temperature of the water is...

Embodiment 3

[0032] Embodiment 3 A kind of method of separating ethylenediamine and water azeotrope

[0033] The ethylenediamine and water azeotrope are introduced into the pressurized rectification column A, the operating pressure is controlled at 1.05Mpa, the temperature at the bottom of the tower is controlled at 215°C, the temperature at the top of the tower is controlled at 198°C, the water is distilled from the top of the tower, the bottom of the tower is Ethylenediamine is extracted; the reflux ratio is 18~21; the output from the top of the tower is water with a purity of 99.5%, and the bottom of the tower is ethylenediamine with a purity of 99.9%.

[0034] The ethylenediamine and water azeotrope: water 20wt%, ethylenediamine 75%~79wt%, organic amine mixture 1%~5%, the components of the organic amine mixture include diethylenetriamine, aminopiperazine, Hydroxyethylethylenediamine.

[0035] The water evaporated from the top of the tower is introduced into the waste heat recovery dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com