Magnetron components, magnetron sputtering chambers and semiconductor processing equipment

A magnetron and component technology, which is used in magnetron, sputtering, metal material coating processes, etc., can solve the problem of large corrosion degree, small corrosion degree in the central area of the target, and poor uniformity of the whole target sputtering, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

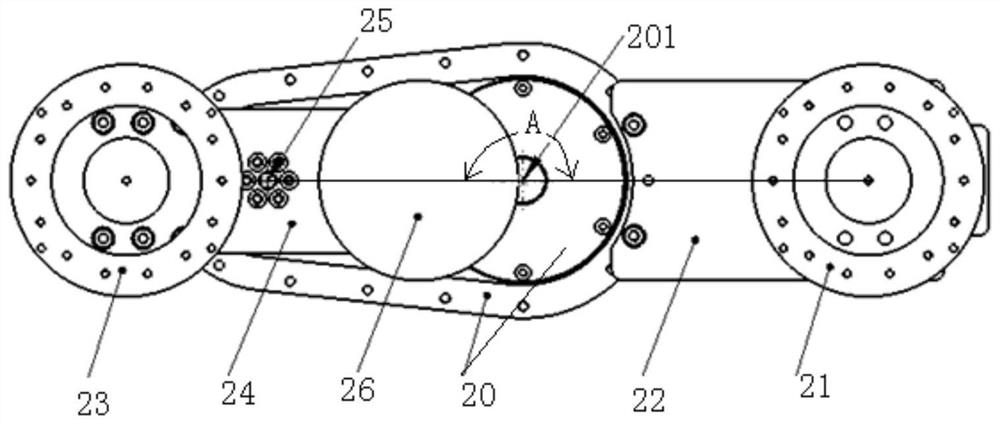

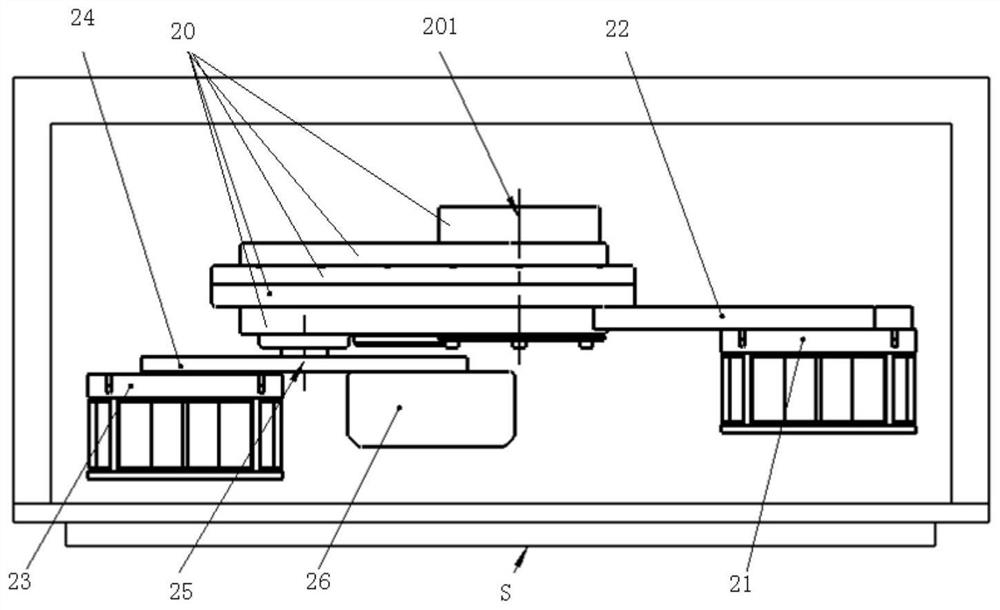

[0023] figure 1 The bottom view of the magnetron assembly provided for the embodiment of the present invention; figure 2 for figure 1 Front view of the magnetron assembly shown in application. Please also refer to Figure 1~2 , The magnetron assembly provided by the embodiment of the present invention includes: a rotating mechanism 20 , a first magnetron 21 , a first rotating arm 22 , a second magnetron 23 , a second rotating arm 24 and a rotating shaft 25 . Wherein, the rotating mechanism 20 is used to rotate along its central axis 201 under the driving of the driving mechanism; the first magnetron 21 is fixedly connected with the rotating mechanism 20 through the first rotating arm 22, so as to drive the first The magnetron 21 rotates around the central axis 201; the second magnetron 23 is fixedly connected with the second rotating arm 24, and the second rotating arm 24 is connected with the rotating mechanism 20 through the rotating shaft 25, so as to drive the second r...

Embodiment 2

[0035] An embodiment of the present invention also provides a magnetron sputtering chamber, which includes a magnetron assembly, and the magnetron assembly adopts the magnetron assembly provided in Embodiment 1 above.

[0036] The magnetron sputtering chamber provided in the embodiment of the present invention adopts the magnetron assembly provided in Embodiment 1 of the present invention, so the utilization rate of the target material and the process quality of the thin film can be improved.

Embodiment 3

[0038] An embodiment of the present invention provides a semiconductor processing device, including: the magnetron sputtering chamber provided in Embodiment 2 above.

[0039] The semiconductor processing equipment provided in the embodiment of the present invention adopts the magnetron sputtering chamber provided in the above-mentioned embodiment 2, so the utilization rate of the target material and the process quality of the thin film can be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com