Algicide production method based on moss extraction liquid and application of algicide

A technology of algaecide and extract, which is applied in the field of preparation of algae inhibitor based on moss extract, can solve the problems of drinking water safety threats, reduce the content of algae toxins, release a large amount of algae toxins, etc., achieve convenient acquisition and reduce production costs , little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

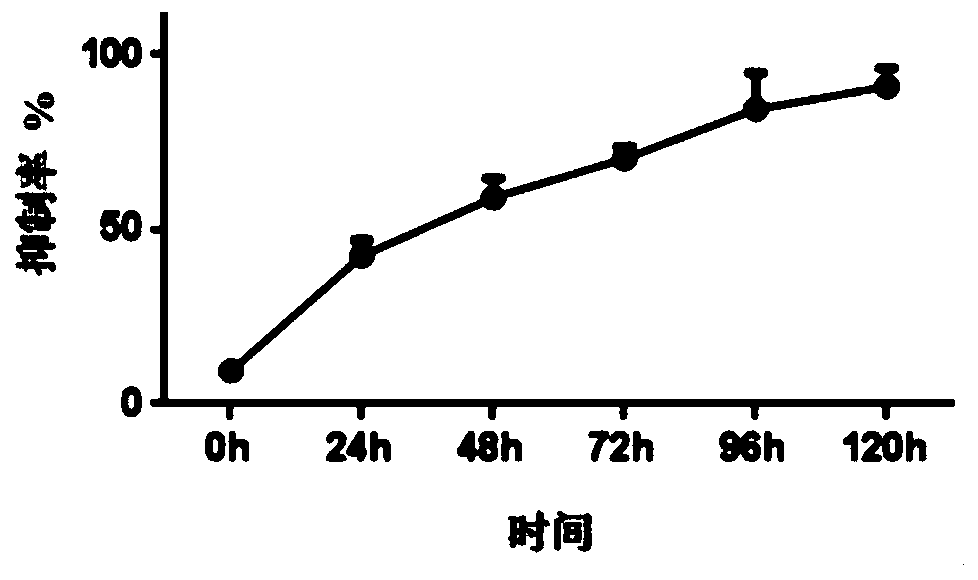

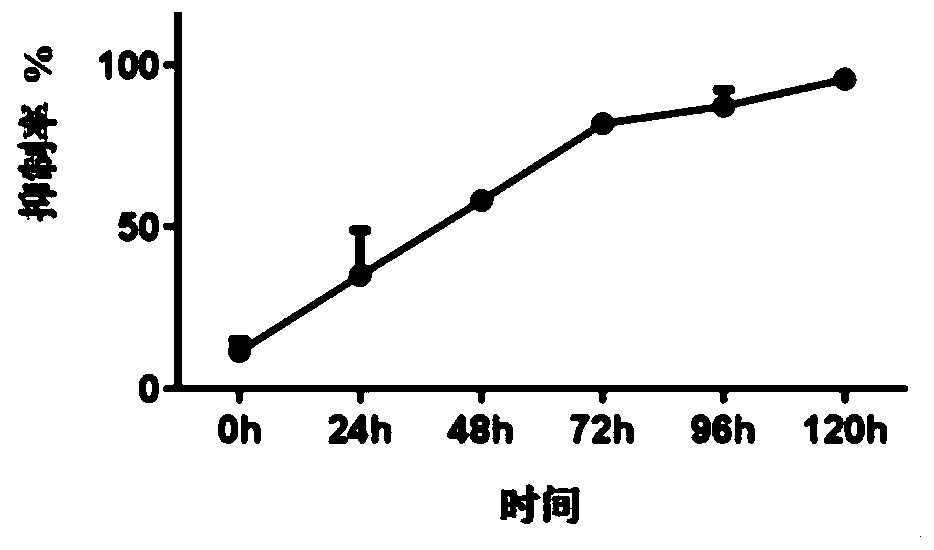

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

[0031] like figure 1 Shown, a kind of preparation method of algastatic agent based on moss extract, concrete steps are as follows:

[0032] Step 1: Take 180g of moss, wash it with distilled water, grind it with a grinder, and place it in an oven to dry at 60°C until it reaches a constant weight (the drying time in this example is 12 hours), so as to obtain moss powder. When drying, the moss is spread flat on the ceramic tray, and the moss is not overlapped.

[0033] Step 2, the moss powder obtained in step 1 is equally divided into two parts. One part of the moss powder was added to the ethanol solution with a volume concentration of 70% according to the ratio of solid to liquid of 1:10, and soaked at 25°C for 48 hours to obtain an ethanol extract. Another portion of moss powder was added into deionized water at a solid-to-liquid ratio of 1:10, and soaked at 25°C for 48 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com