Infant milk powder simulating fatty acid structure and composition of breast milk

A fatty acid and vegetable fat powder technology, applied in whey, dairy products, applications, etc., can solve the problems of unfavorable digestion and absorption and metabolism and excretion of infants' brain and retinal development, immature digestion and absorption, metabolism and excretion, etc., to achieve Effects of lowering low-density lipoprotein cholesterol, enhancing cognitive function development, promoting fatty acid absorption and calcium absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

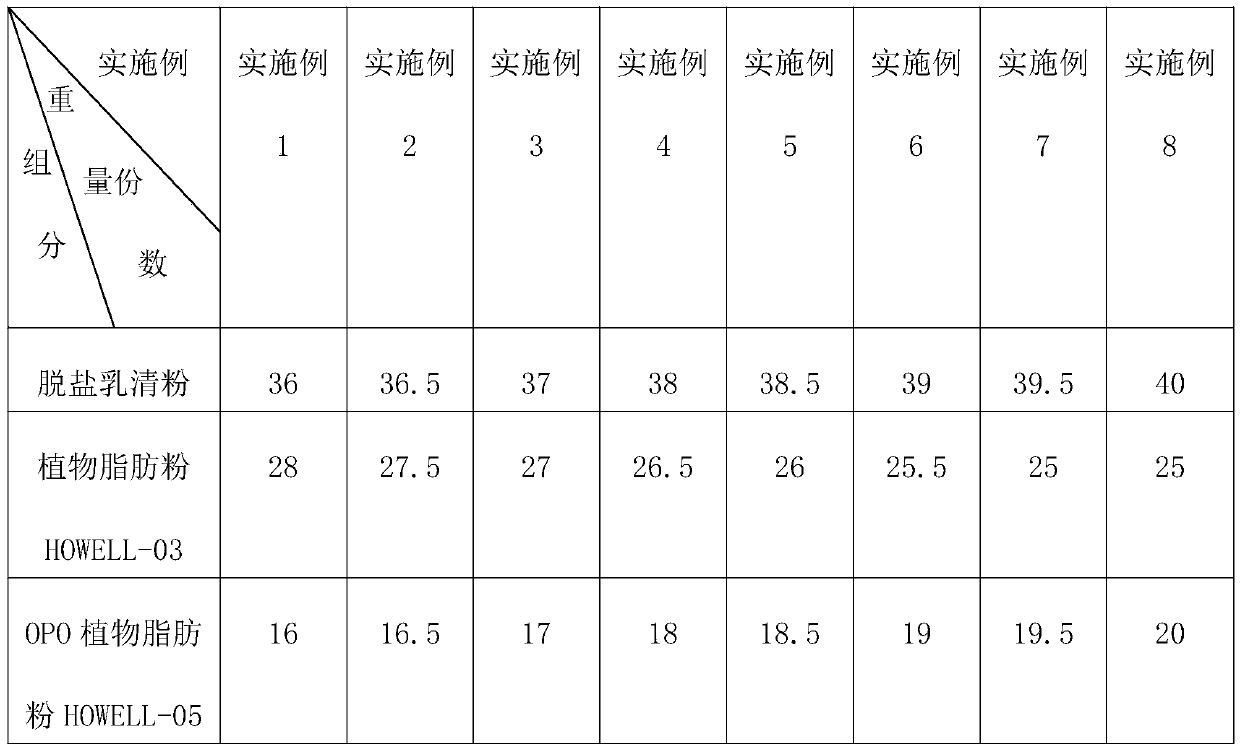

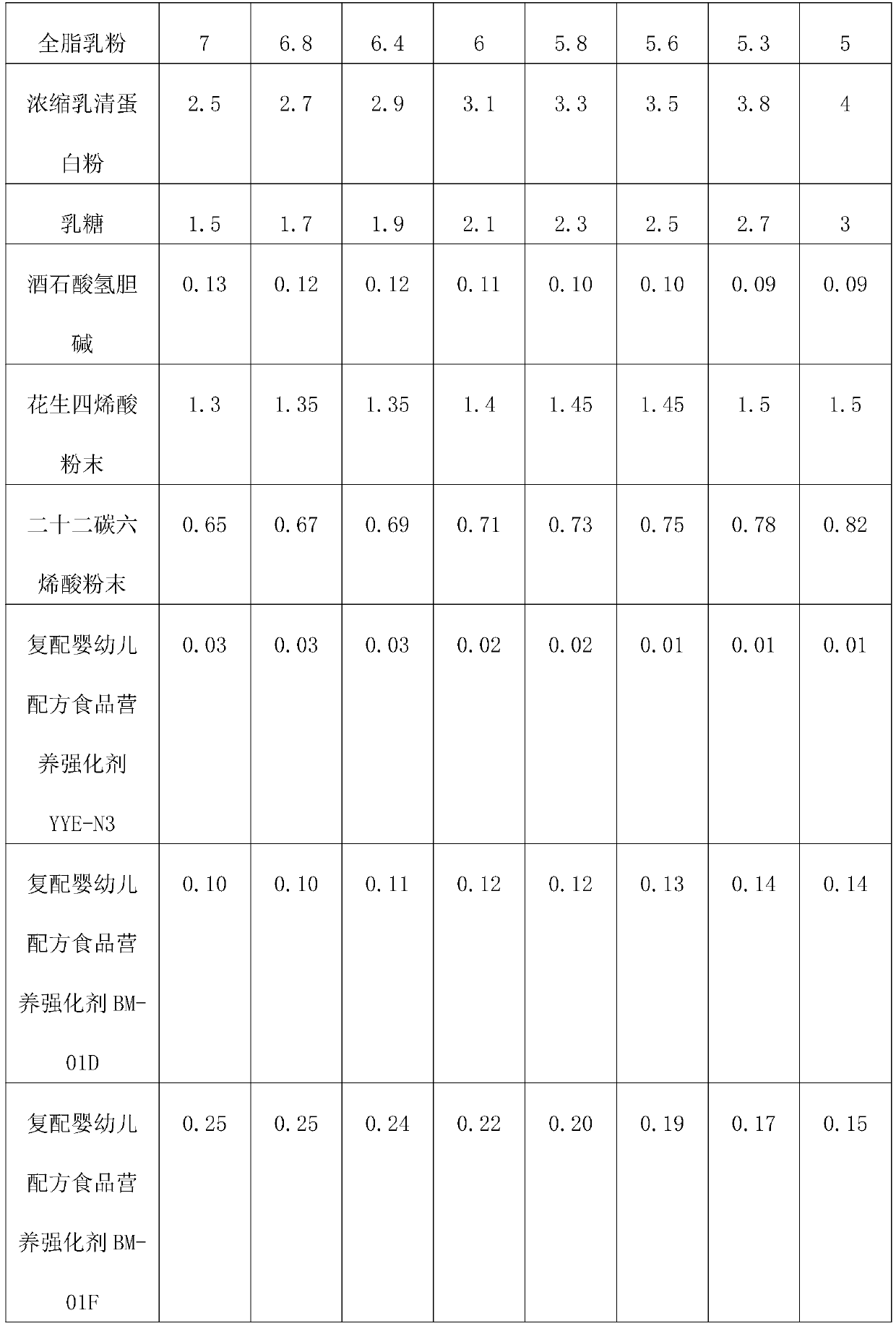

Embodiment 1-8

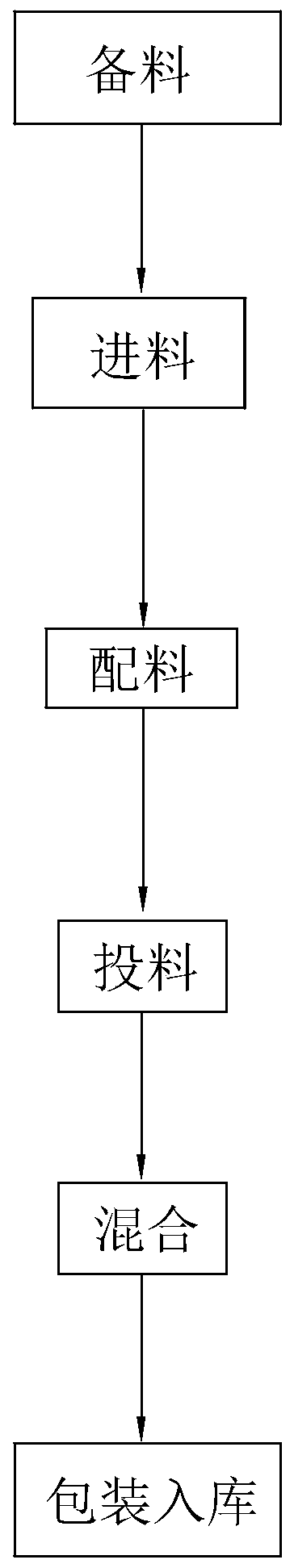

[0047] Embodiment 1-8: An infant milk powder that simulates the structure and composition of breast milk fatty acids, each component and its corresponding parts by weight are shown in Table 1, and its preparation method includes the following steps:

[0048] Material preparation: the outer packaging of various purchased materials should be placed under the radiation intensity of 70μW / cm 2 irradiated under the ultraviolet lamp for 10 minutes, and then put them into the air shower room and air shower for 65s under the high wind speed of 25m / s;

[0049] Feed: The outer packaging of the prepared materials passes through the conveyor belt with a radiation intensity of 70μW / cm 2 Ultraviolet lamps, and then sterilize the outer packaging of the material for 70s in the large bag tunnel sterilizer and the automatic bag outer sterilizer respectively;

[0050] Ingredients: Lactose, choline bitartrate, arachidonic acid powder, docosahexaenoic acid powder, compound infant formula nutrition...

Embodiment 9-20

[0058] Example 9-20: An infant milk powder that simulates the structure and composition of breast milk fatty acids. The difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 2. The preparation method includes Follow the steps below:

[0059] Material preparation: the outer packaging of various purchased materials should be placed under the radiation intensity of 70μW / cm 2 irradiated under the ultraviolet lamp for 10 minutes, and then put them into the air shower room and air shower for 65s under the high wind speed of 25m / s;

[0060] Feed: The outer packaging of the prepared materials passes through the conveyor belt with a radiation intensity of 70μW / cm 2 Ultraviolet lamps, and then sterilize the outer packaging of the material for 70s in the large bag tunnel sterilizer and the automatic bag outer sterilizer respectively;

[0061] Premixing: Lactose, choline bitartrate, arachidonic acid powder, docosahexaenoic acid powder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com