Full-automatic core body binding robot

A fully automatic and robotic technology, which is applied to the parts and packaging of strapping machinery, can solve problems such as low reliability, narrow application range, and poor precision, and achieve the effects of high automation, stable operation, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

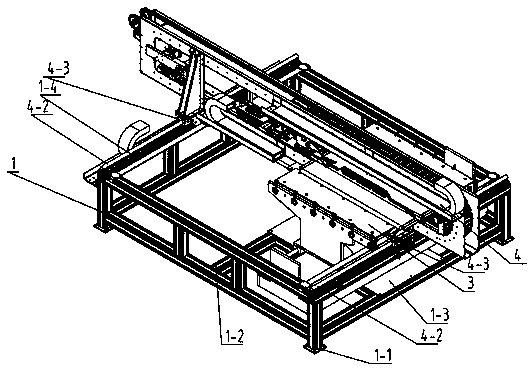

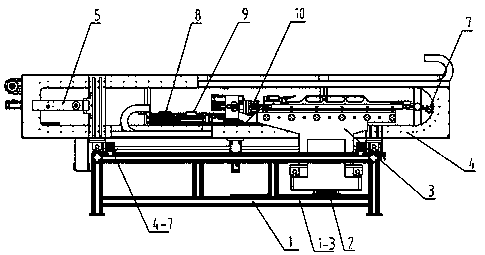

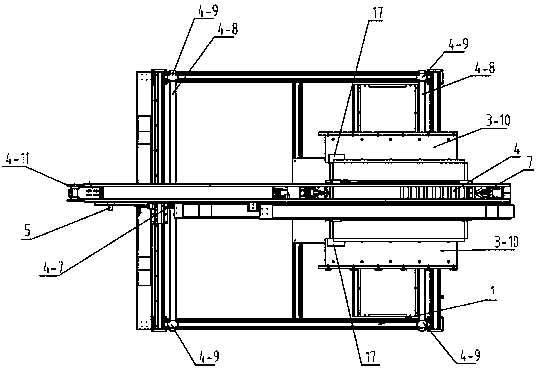

[0108] Such as figure 1 , Figure 2 and image 3 As shown, the technical solution adopted in the present invention includes an equipment base 1, which is the installation basis of the entire equipment. In order to ensure that the equipment base 1 has sufficient rigidity, the equipment base 1 adopts an aluminum alloy profile of 80mm×80mm Connected into one body to form a rectangular equipment base with upper and lower layers, four feet 1-1 are arranged under the four-corner column of the equipment base 1, and the equipment base 1 can be adjusted horizontally through the feet 1-1; A lifting cylinder mounting plate 1-3 is installed in the middle of the two lower longitudinal beams 1-2 on the right side of the equipment base 1, and a lifting cylinder 2 is installed at the center of the lifting cylinder mounting plate 1-3. A movable workpiece bracket assembly 3 for supporting the core is installed, and a binding unit 4 is installed on the two upper longitudinal beams 1-4 on the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com