Method for removing heavy metal chromium by preparing biological magnetite with dissimilatory iron reducing bacteria

A technology for dissimilating iron and magnetite, which is applied in the field of preparing biological magnetite to remove heavy metal Cr, can solve the problems of restricting large-scale application process and strict microbial culture conditions, and achieves the advantages of overcoming toxicity inhibition, increasing treatment cost and high concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

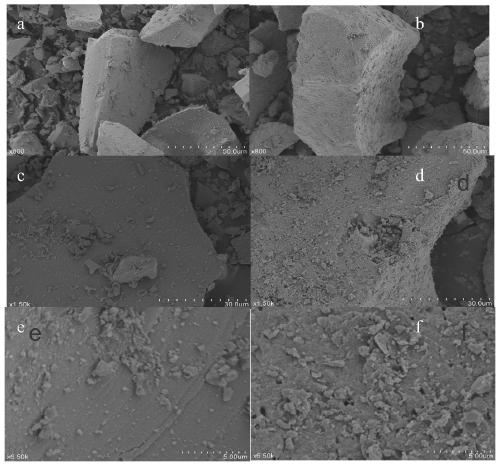

[0041] Embodiment 1: the physical characteristics of biological magnetite

[0042] (1) The dissimilatory iron-reducing bacterium Klebsiella sp.KB52 was inoculated in a 150mL anaerobic bottle (containing 100mL basal medium) according to the inoculum amount of 1%, filled with nitrogen for 5 minutes to ensure anaerobic culture environment, 30°C, 120r / min, shaker culture ;

[0043] Basal medium composition (g / L): glucose 10, yeast extract 2.0, tryptone 1.0, NaCl 30.0, K 2 HPO 4 1.5, NaHCO 3 1.5, Fe(OH) 3 400mg / L, pH 7.0±0.2; NaHCO 3 First prepare a solution with a concentration of 50g / L, sterilize it by filtration, and add it to the basal medium at 30mL / L;

[0044] In the above-mentioned artificial synthesis of Fe(OH) 3In the redox culture system in which glucose is the electron acceptor and glucose is the electron donor, the strain KB52 can use the insoluble Fe(III) form for dissimilatory iron reduction, and the accumulated Fe(II) concentration after 96 hours of culture i...

Embodiment 2

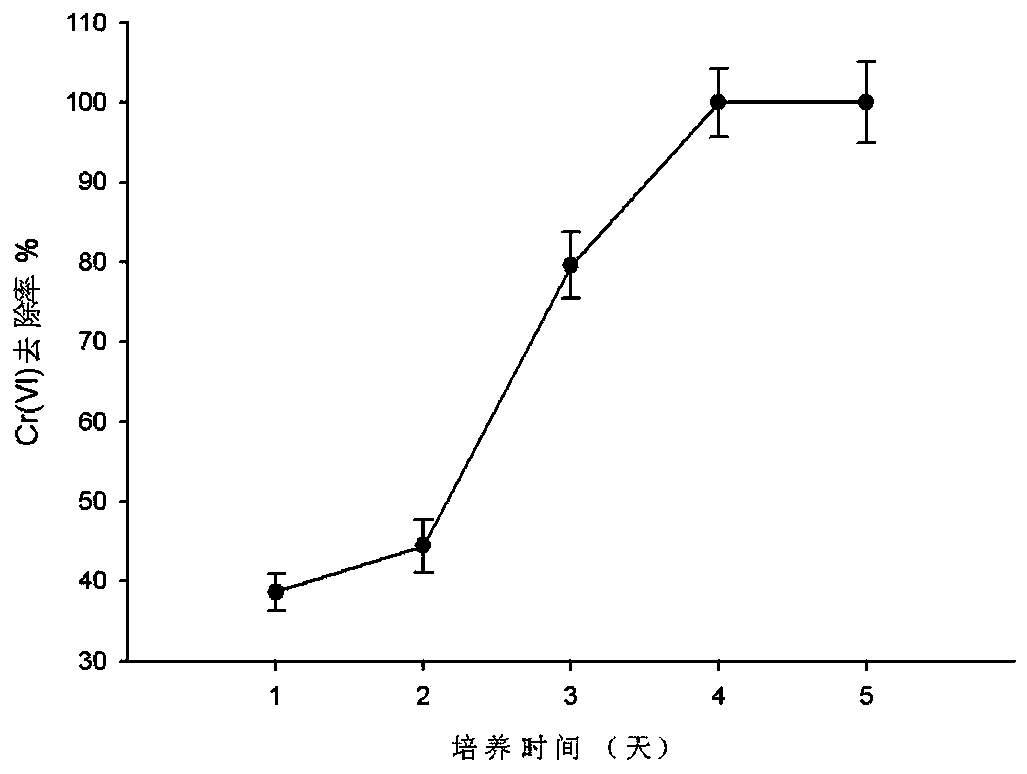

[0047] The impact of embodiment 2 cultivation time on Cr(VI) removal rate

[0048] (1) The dissimilatory iron-reducing bacterium Klebsiella sp.KB52 was inoculated in a 150mL anaerobic bottle (containing 100mL basal medium) according to the inoculum amount of 1%, filled with nitrogen for 5 minutes to ensure anaerobic culture environment, 30°C, 120r / min, shaker culture ;

[0049] Basal medium composition (g / L): glucose 10, yeast extract 2.0, tryptone 1.0, NaCl 30.0, K 2 HPO 4 1.5, NaHCO 3 1.5, Fe(OH) 3 400mg / L, pH 7.0±0.2; NaHCO 3 First prepare a solution with a concentration of 50g / L, sterilize it by filtration, and add it to the basal medium at 30mL / L;

[0050] During the cultivation process, adopt the same method as in Example 1 to collect the biomagnetite precipitate formed in the reduction process of bacterial strain KB52 dissimilated iron every 24h, dry it into powder, and add biomagnetite to the containing In the liquid to be treated of 40mg / L Cr (VI), adjust pH ...

Embodiment 3

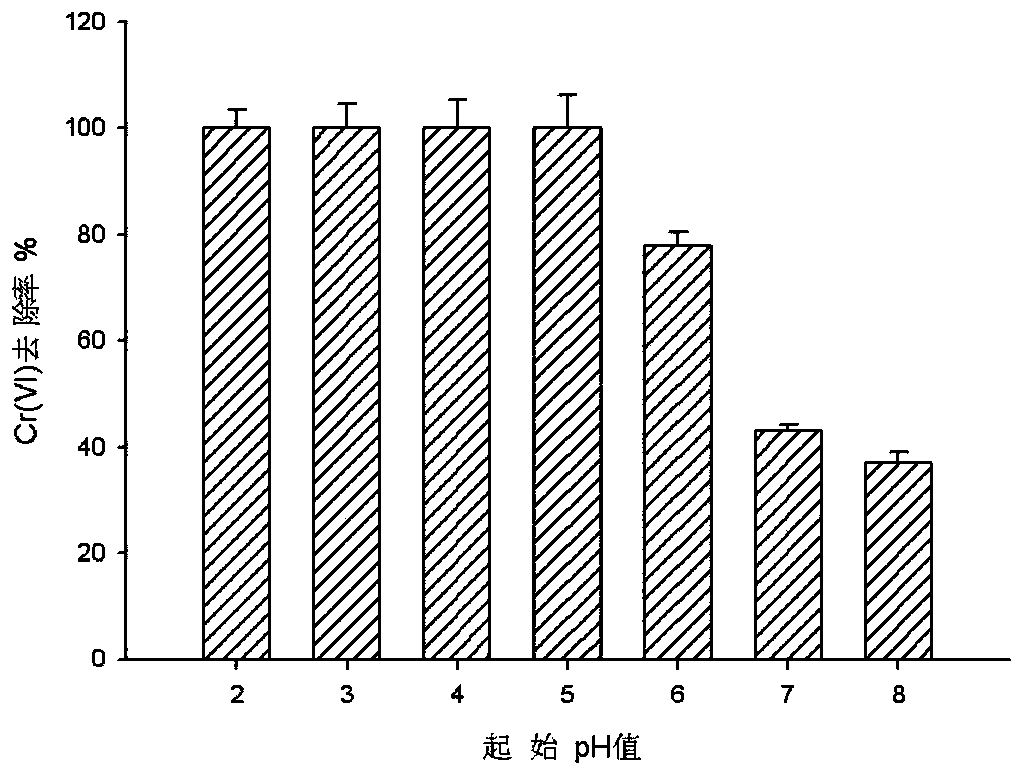

[0052] The influence of embodiment 3 pH value on Cr(VI) removal rate

[0053] According to the method of Example 1, when the bacterial strain KB52 was cultured in the redox culture system for 4 days, it was centrifuged, precipitated and dried to prepare bio-magnetite. Bio-magnetite was added to the liquid to be treated with different initial pH values containing 40mg / L Cr(VI) in a ratio of 2g / L, and treated for 10h, the results were as follows image 3 .

[0054] Depend on image 3 It can be seen that the bio-magnetite prepared by strain KB52 has different removal efficiencies for Cr(VI) in solutions with different pH values. When the pH value is less than 6.0, the removal efficiency of Cr(VI) by bio-magnetite is relatively high, and the removal effect is obvious. When the pH value of Cr(VI) solution was 2.0, 3.0, 4.0 and 5.0, the removal rate of Cr(VI) by biological magnetite reached 100%; when the pH value of Cr(VI) solution was 6.0, the removal rate of Cr(VI) by biolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com