Pervious concrete aerated brick

A technology of permeable concrete and air-entrained brick, which is applied in the field of building materials, can solve the problems of reduced compressive strength of permeable concrete, easy fracture, reduced hardness of permeable concrete aerated brick, etc., and achieves good affinity, water retention, and water permeability. The effect of reinforcement and improved molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

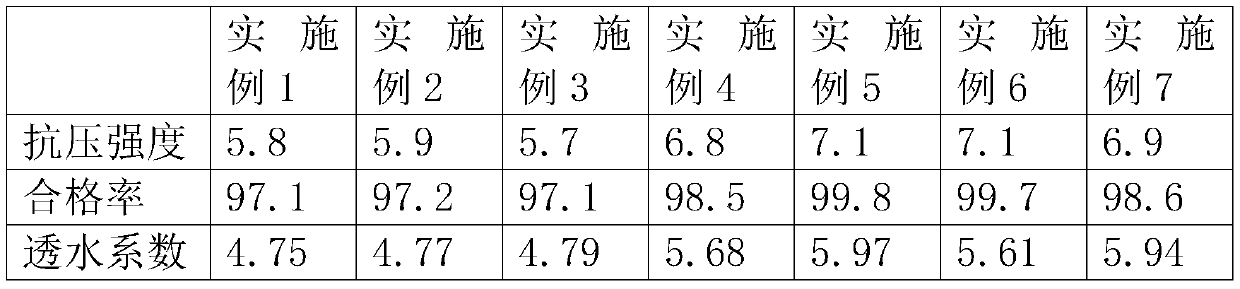

Examples

Embodiment 1

[0052] A permeable concrete aerated brick, comprising the following components in parts by mass:

[0053] Fly ash 43kg; stone powder 22kg; lime 10kg; water 58kg; Portland cement 10kg; gypsum 3kg; aluminum powder 0.08kg; steel fiber 0.08kg; isinglass powder 0.15kg.

[0054] The preparation method of permeable concrete aerated brick is as follows:

[0055] (1) In a 200L stirring tank, stir at a speed of 120r / min. Under normal temperature conditions, add 43kg of fly ash, 22kg of stone powder, 10kg of lime, 58kg of water, 10kg of Portland cement, 3kg of gypsum, and steel fiber 0.08kg, keep the temperature at 46°C, react for 150s, stir evenly to get the premix;

[0056] (2) Add 0.08kg of aluminum powder to the premix obtained in (1) while stirring, keep the temperature at 52°C, and react for 50s;

[0057] (3) After cooling to room temperature, add fish gelatin powder 0.15 kg while stirring, and stir evenly to obtain concrete slurry;

[0058] (4) After stirring for 4 minutes, pour ...

Embodiment 2

[0062] A permeable concrete aerated brick, comprising the following components in parts by mass:

[0063] Fly ash 50kg; stone powder 26kg; lime 12kg; water 63kg; Portland cement 12kg; gypsum 3.5kg; aluminum powder 0.09kg; steel fiber 0.09kg; isinglass powder 0.17kg.

[0064] The preparation method of permeable concrete aerated brick is as follows:

[0065] (1) In a 200L stirring tank, stir at a speed of 120r / min. Under normal temperature conditions, add 50kg of fly ash, 26kg of stone powder, 12kg of lime, 63kg of water, 12kg of Portland cement, 3.5kg of gypsum, steel Fiber 0.09kg, keep the temperature at 46°C, react for 150s, stir evenly to get the premix;

[0066] (2) Add 0.09kg of aluminum powder to the premix obtained in (1) while stirring, keep the temperature at 52°C, and react for 50s;

[0067] (3) After cooling to room temperature, add fish gelatin powder 0.17kg while stirring, and stir evenly to obtain concrete slurry;

[0068] (4) After stirring for 4 minutes, pour...

Embodiment 3

[0072] A permeable concrete aerated brick, comprising the following components in parts by mass:

[0073] Fly ash 58kg; stone powder 30kg; lime 14kg; water 78kg; Portland cement 14kg; gypsum 4kg; aluminum powder 0.1kg; steel fiber 0.1kg; isinglass powder 0.2kg.

[0074] The preparation method of permeable concrete aerated brick is as follows:

[0075] (1) In a 200L stirring tank, stir at a speed of 120r / min. Under normal temperature conditions, add 58kg of fly ash, 30kg of stone powder, 14kg of lime, 78kg of water, 14kg of Portland cement, 4kg of gypsum, and steel fiber 0.1kg, keep the temperature at 46°C, react for 150s, stir evenly to get the premix;

[0076] (2) Add 0.1kg of aluminum powder to the premix obtained in (1) while stirring, keep the temperature at 52°C, and react for 50s;

[0077] (3) After cooling to room temperature, add 0.2 kg of fish gelatin powder while stirring, and stir evenly to obtain concrete slurry;

[0078] (4) After stirring for 4 minutes, pour t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com