High temperature resistant organic phosphonic acid polymer fluid loss agent, and preparation method and applications thereof

A technology of organic phosphonic acid and fluid loss reducer, which is applied in the field of anti-high temperature drilling fluid fluid loss reducer and its preparation, high temperature resistant organic phosphonic acid polymer fluid loss reducer and its preparation, and can solve the performance index of fluid loss reduction It is difficult to meet the construction requirements and other problems, and achieve the effect of being suitable for industrial application, strong anti-calcium ability, and good filtration loss reduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

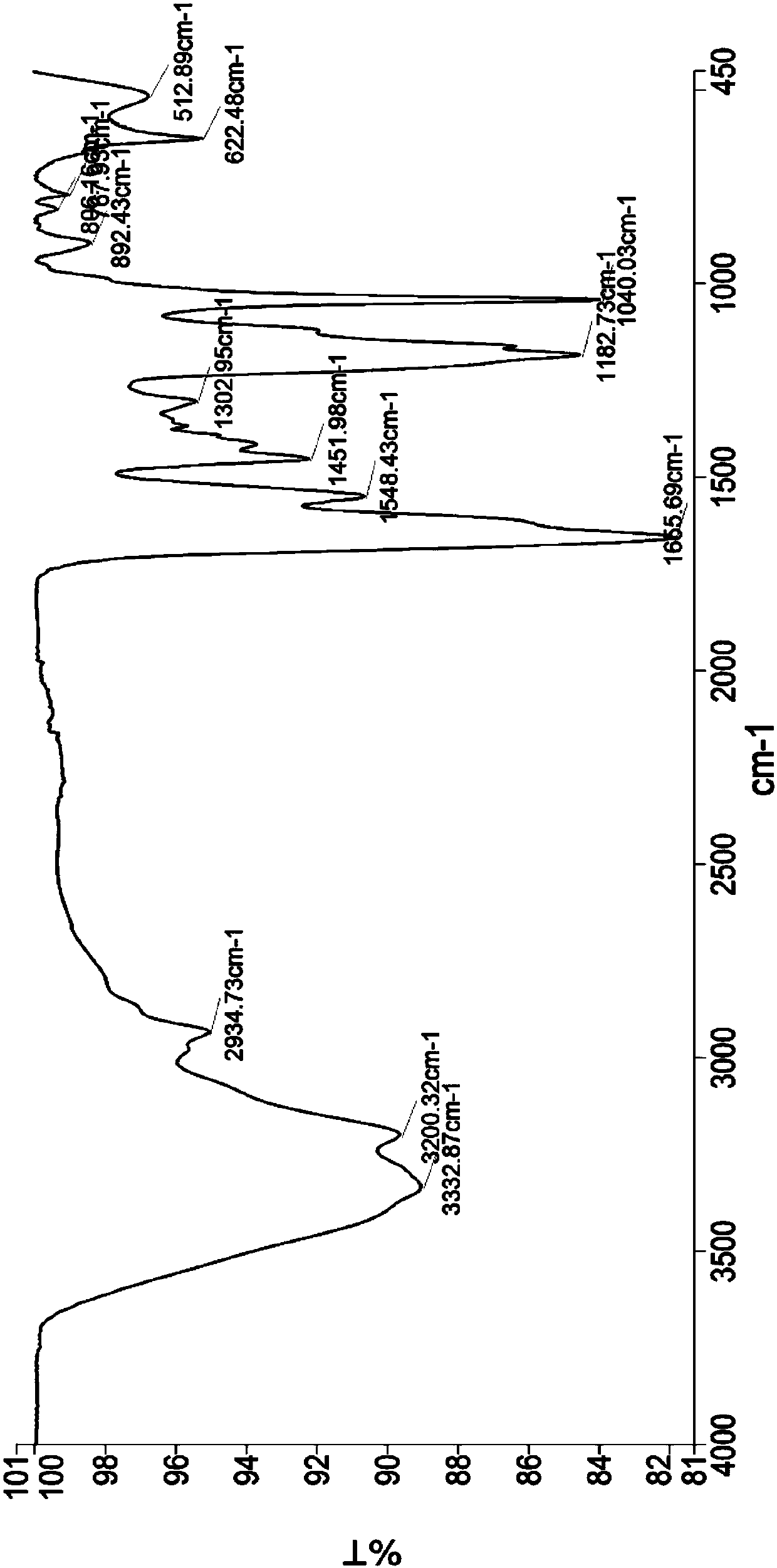

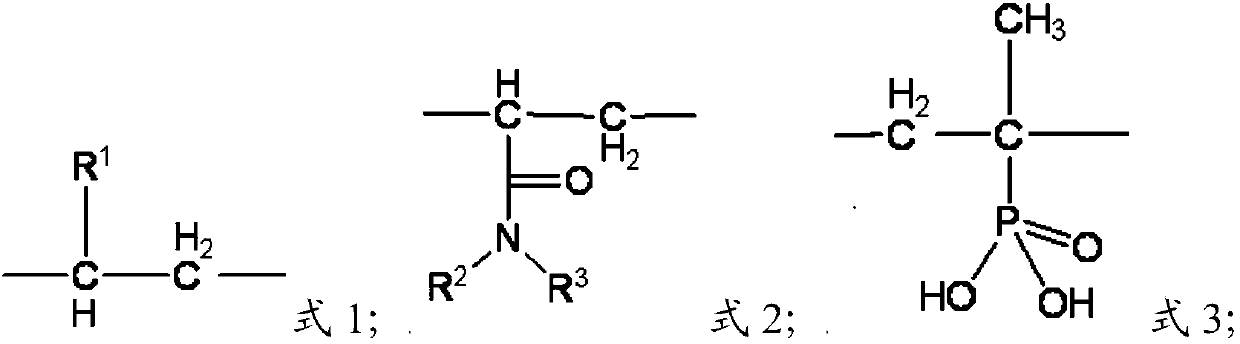

[0043] Simultaneously, the present invention provides a kind of preparation method of anti-high temperature organic phosphonic acid polymer fluid loss reducer, comprising the following steps: mixing isopropene phosphonic acid monomer, acrylamide monomer and monomer containing sulfonic acid group in Polymerization under the action of an initiator, and then neutralized with sodium hydroxide or potassium hydroxide to obtain a high temperature resistant organic phosphonic acid polymer fluid loss reducer;

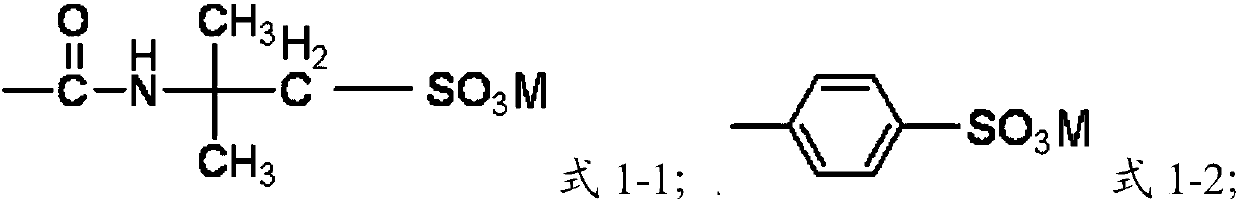

[0044] The acrylamide monomer is selected from acrylamide, 2-methacrylamide, N-methacrylamide, N-ethylacrylamide or N,N-dimethylacrylamide; the sulfonic acid group The monomer is selected from 2-acrylamido-2-methylpropanesulfonic acid, p-vinylbenzenesulfonic acid or allylsulfonic acid.

[0045] In order to meet the technical requirements for drilling in high-temperature, high-salt calcium formations, the present invention researches and prepares a high-temperature resistant orga...

Embodiment 1

[0058] Mix isopropenylphosphonic acid (IPPA) with acrylamide (AM) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) according to the material ratio of 10%:70%:20%, and then dissolve In water, a monomer mixture aqueous solution with a mass fraction of 30% was prepared; potassium persulfate accounting for 0.3% of the total mass of the monomer mixture was prepared with a 2.0% initiator aqueous solution.

[0059] Add the monomer mixture solution into the reaction kettle, pass in argon to evacuate the air in the system, and raise the temperature to 60°C; add the aqueous initiator solution into the reaction kettle in batches, and the addition speed is determined by the temperature of the reaction kettle. Over 90°C shall prevail; after adding the initiator aqueous solution, raise the temperature of the system to 80°C and react for 2 hours. After the reaction, neutralize the system with sodium hydroxide until the pH value is 8, and the obtained product is dried and pulverized , tha...

Embodiment 2~11

[0062] According to the method of Example 1, the organic phosphonic acid polymer fluid loss reducer was prepared respectively; different formulations and conditions are shown in Table 1:

[0063] The substance consumption and reaction condition of polymerization reaction among the embodiment 2~11 of table 1

[0064]

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com