Crankshaft ventilation system, turbocharged engine and automobile

A technology for turbocharging and ventilation systems, applied in crankcase ventilation, engine components, machines/engines, etc., can solve the problems of high cost, many connecting pipes, and large space occupied by the crankshaft ventilation system. The effect of reducing the number of connecting pipes and reducing the high cost problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

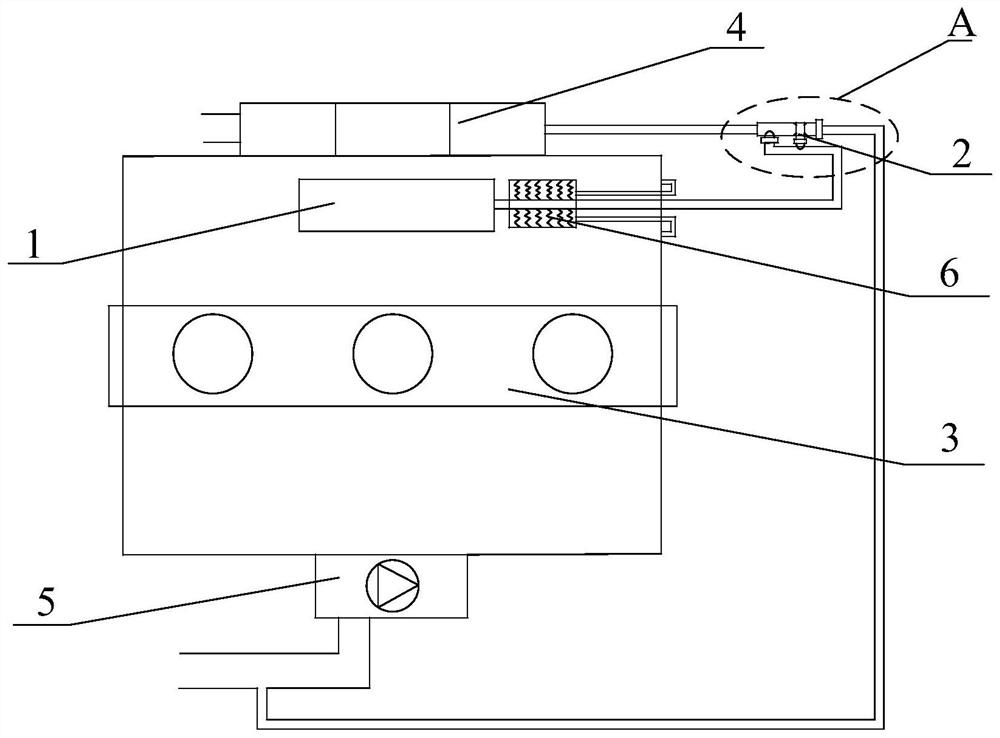

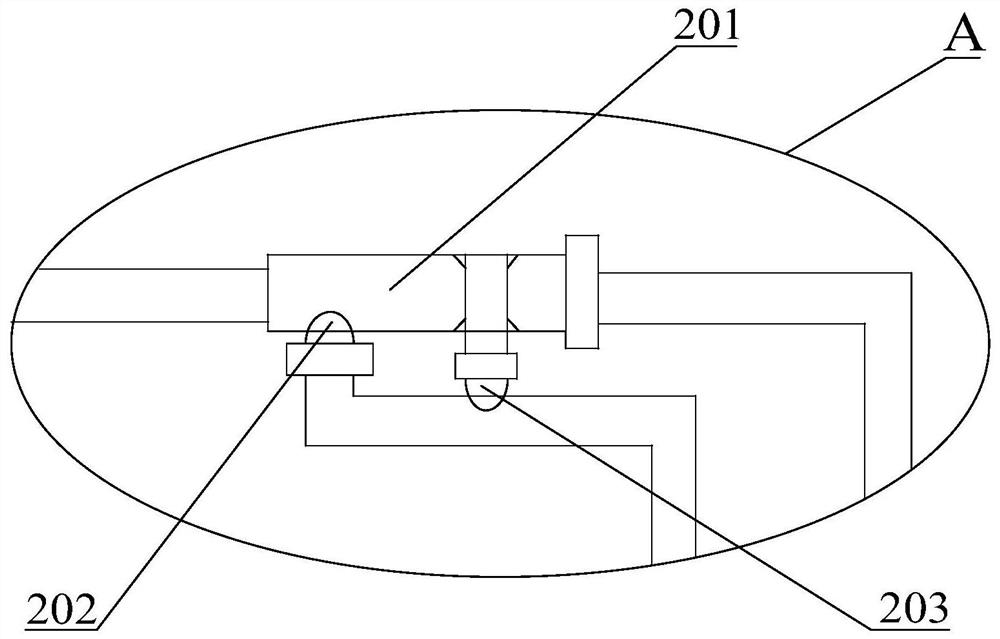

[0045] Such as figure 1 , figure 2 as shown, figure 1 It shows a schematic structural diagram of the first crankshaft ventilation system provided by the embodiment of the present application; figure 2 for figure 1 Schematic diagram of the enlarged structure at A.

[0046] The first crankshaft ventilation system is applied to the turbocharged engine 3, including the oil-air separator 1, and also includes the direction control assembly 2, and the direction control assembly 2 is respectively connected with the intake manifold 4, the intake manifold 4 and the turbocharged engine 3 through pipelines. The turbocharger 5 of the turbocharged engine 3 communicates with the oil-air separator 1; wherein, the direction control assembly 2 controls the gas separated from the oil-air separator 1 to flow to the intake manifold 4 according to the working state of the turbocharger 5 Or turbocharger 5.

[0047] From this analysis, it can be known that in the crankshaft ventilation system ...

Embodiment 2

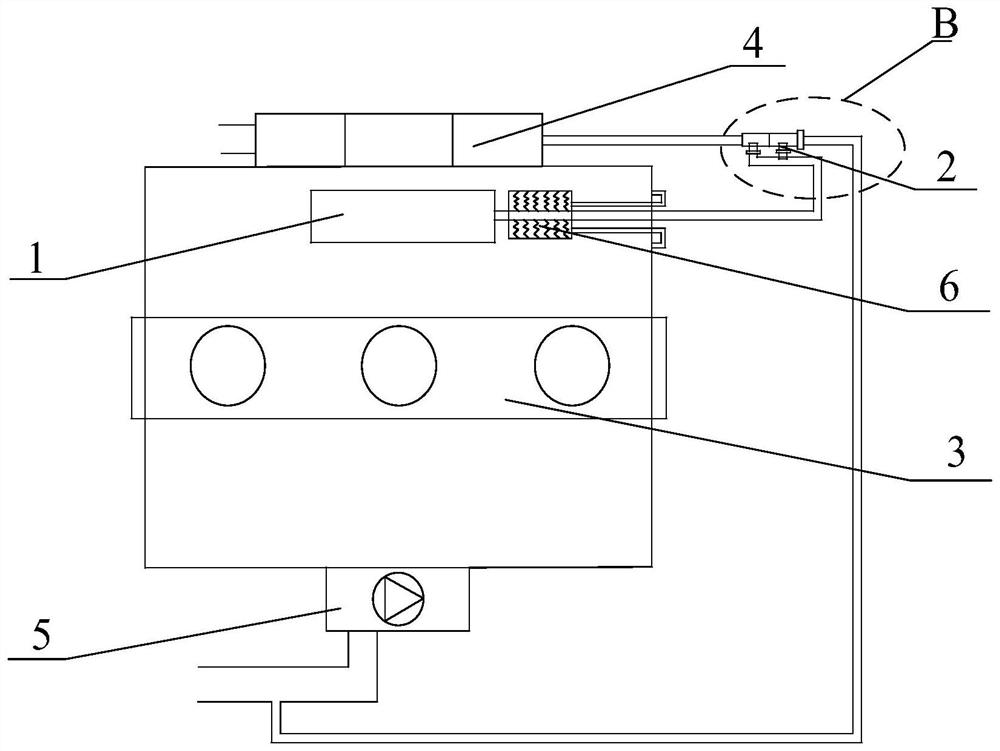

[0061] Such as image 3 , Figure 4 as shown, image 3 A schematic structural diagram of the second crankshaft ventilation system provided in the embodiment of the present application; Figure 4 for image 3 Schematic diagram of the enlarged structure at B.

[0062] The second crankshaft ventilation system is applied to the turbocharged engine 3, including the oil-air separator 1, and also includes the direction control assembly 2, and the direction control assembly 2 is respectively connected with the intake manifold 4, the intake manifold 4, and the turbocharged engine 3 through pipelines The turbocharger 5 of the turbocharged engine 3 communicates with the oil-gas separator 1;

[0063] Wherein, the direction control assembly 2 controls the gas separated from the oil-gas separator 1 to flow to the intake manifold 4 or the turbocharger 5 according to the working state of the turbocharger 5;

[0064] Specifically, the direction control assembly 2 includes a first connecti...

Embodiment 3

[0074] Such as Figure 5 , Image 6 as shown, Figure 5 A partial structural schematic diagram of a turbocharged engine provided in an embodiment of the present application; Image 6 for Figure 5 Schematic diagram of the enlarged structure at C.

[0075] A turbocharged engine 3 includes a first crankshaft ventilation system.

[0076] In addition, the turbocharged engine 3 may also include a second crankshaft ventilation system, but since the first crankshaft ventilation system and the second crankshaft ventilation system have the same functional effect, the embodiment of the present application only uses the first crankshaft ventilation system. Take the turbocharged engine 3 of the crankshaft ventilation system as an example.

[0077] Preferably, an intercooler 7 is provided between the intake manifold 4 and the turbocharger 5 , and the intercooler 7 is used to cool down the gas pressurized by the turbocharger 5 .

[0078]In the embodiment of the present application, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com