Long-row lamp and assembling method thereof

An assembly method and long-row technology, applied in the direction of slender light sources, lighting devices, air-proof/water-proof devices, etc., can solve the problems of cumbersome parts production processes, high manual production costs, high logistics and storage costs, and increase the heat dissipation effect , performance and cost optimization, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

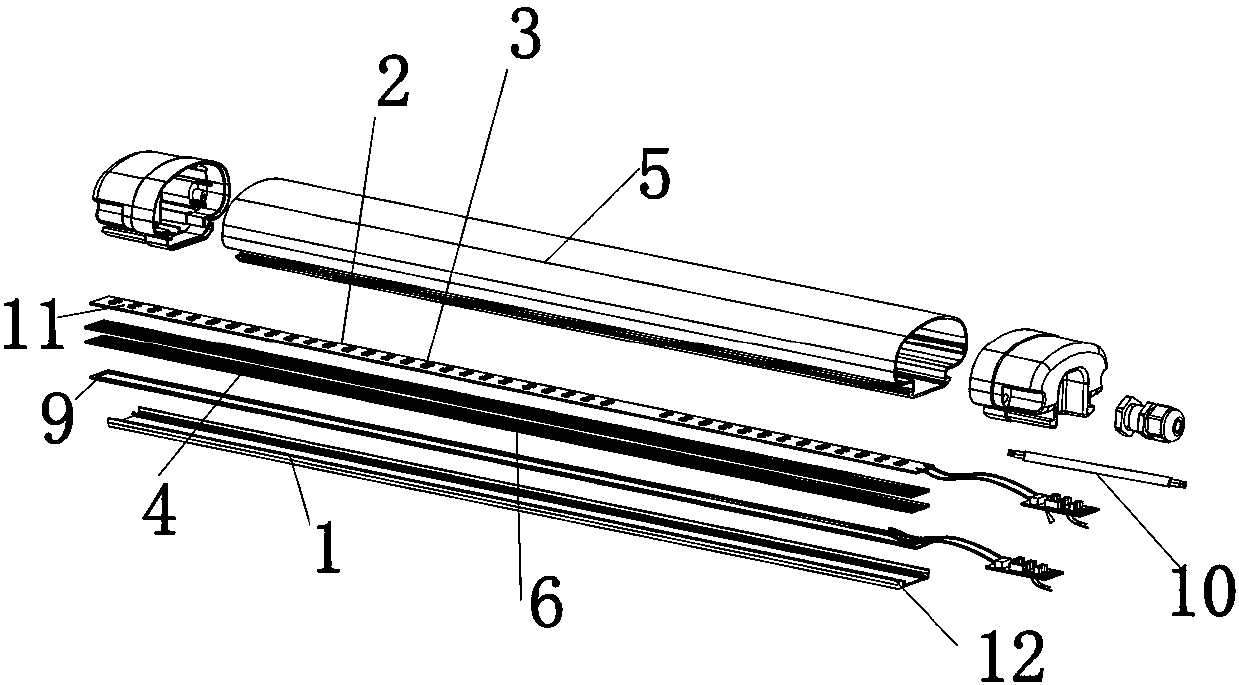

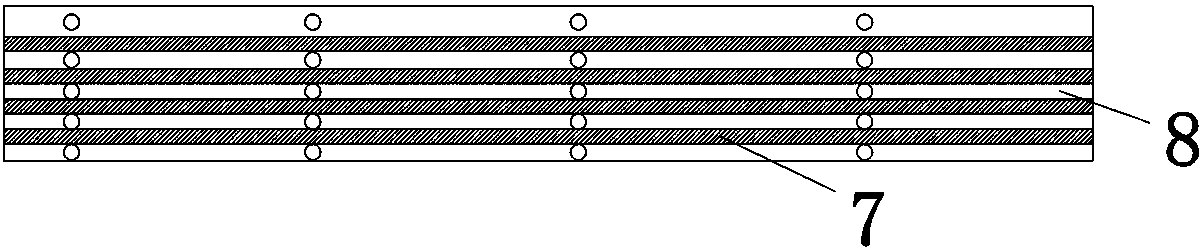

[0022] like Figure 1-Figure 2 The shown embodiment provides a long row of lights, including a mounting base 1, a housing 2 connected to the mounting base 1, and an LED lamp assembly 3 located in the housing 2. Heat sink 4, several heat sinks 4 are spliced together, and the heat sink 4 includes a body 5, which is provided on the end surface of the body 5, and the heat sink 4 is in the shape of a block. The block shape is arranged on the top of the heat sink 4 in a honeycomb structure, and a sealing ring 9 is provided between the installation base 1 and the circuit board 2. The installation base 1 is a heat-conducting metal base, and the metal base is an aluminum base. Gold base or copper base.

[0023] The long row of lamps provided in this embodiment conducts heat through the heat dissipation bar 7 between the heat sink 6 and the heat sink 6. The design of the heat dissipation bar 7 not only ensures the circulation of the air, but also ensures the heat dissipation area. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com