Volatile fragrant component detection and analysis method and application

An analysis method and technology for aroma components, which are applied in the field of volatile substance analysis, can solve the problems that the contribution of aroma compounds cannot be identified, the detection of fragrance components in popping beads is very small, and the volatile characteristics of fragrance components in popping beads are affected, so as to achieve good detection. Effects of Repeatability and Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

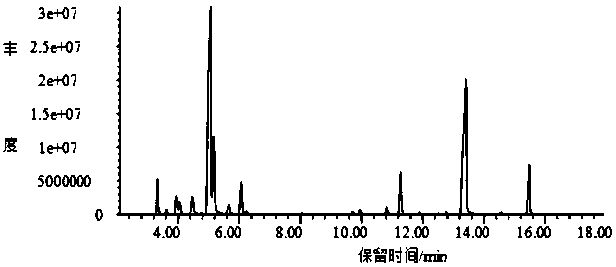

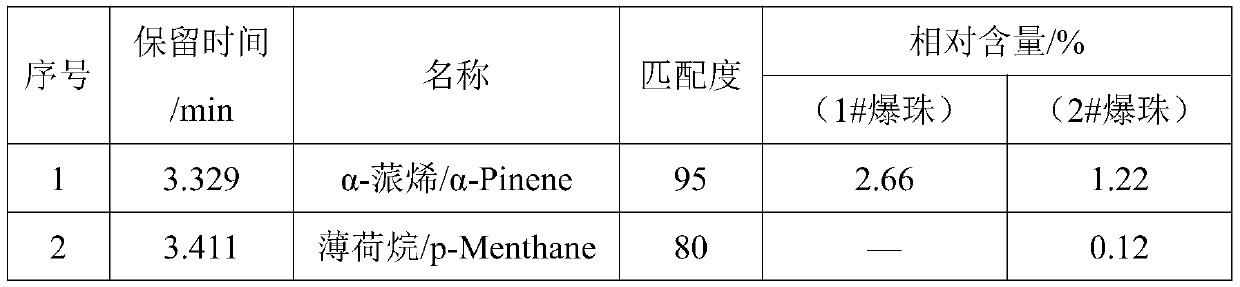

Embodiment 1

[0034] An analysis method for volatile fragrance components, comprising the following steps:

[0035] S1. Sample pretreatment: puncture the popping beads, the liquid in the popping beads flows out and is adsorbed on the smelling stick, put the smelling stick and the shell of the popping beads into the purge and trap tube for purging and trapping, The purge and trap conditions are as follows: the purge time is 2min, the desorption temperature is 250°C, and the desorption time is 2min; the purge temperature is room temperature without heating, the purge gas is high-purity nitrogen, and the transfer line temperature is 230°C ;

[0036] S2. Use GC-MS to separate and characterize the pre-treated samples: perform GC-MS detection and analysis on the samples processed in step S1. The GC-MS analysis conditions are: the chromatographic column is a capillary column, and the chromatographic column specification is 30m ×250μm×0.25μm, the inlet temperature is 230°C, the split ratio is 10:1...

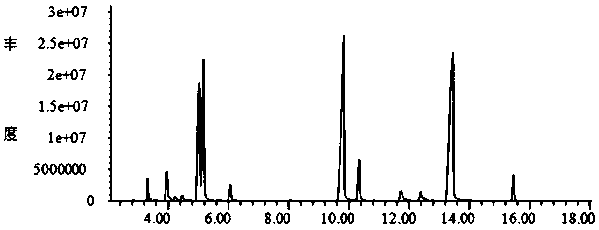

Embodiment 2

[0043] An analysis method for volatile aroma components, the steps of which are basically the same as those in Example 1, the difference being that the object of study is the 2# popping balls in the commercially available double ice popping balls cigarette filter

Embodiment 3

[0045] An analysis method for volatile aroma components, the steps of which are basically the same as those in Example 1, the difference being that Example 1 and Example 2 studied the finished popcorn, and what is studied here is the popcorn that has not been made into popcorn essence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com