Method for reducing error of embedded resistor

A resistance and error technology, applied in the field of circuit board processing and manufacturing, can solve problems such as large resistance error, and achieve the effects of small relative error, good uniformity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] This embodiment provides a method for reducing the resistance error of the embedded resistor, which specifically includes the following steps:

[0029] Step 1: Make the conductive traces of the PCB:

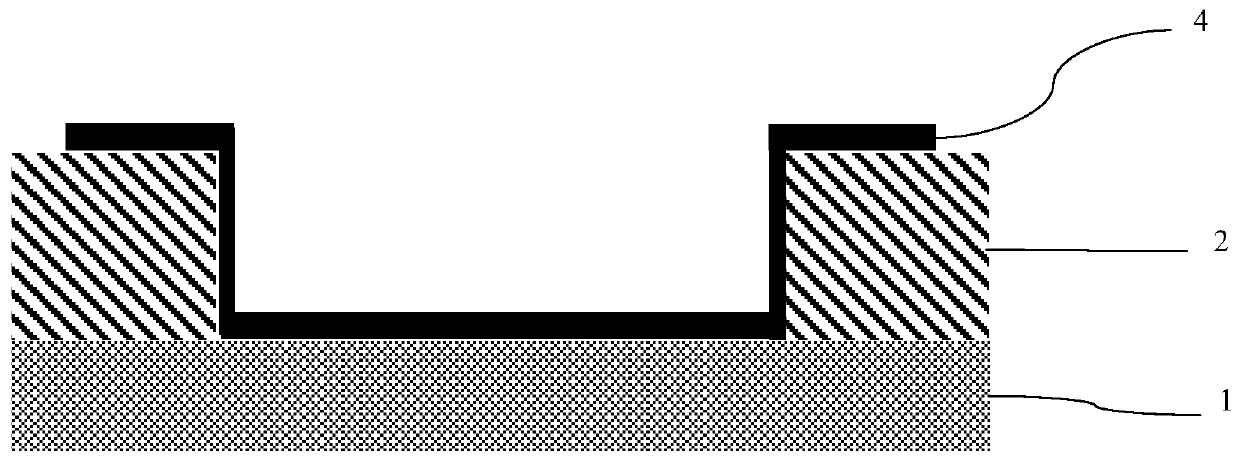

[0030] Use the epoxy resin double-sided copper-clad laminate with a dielectric layer thickness of 100 μm and a copper thickness of 12 μm produced by Shengyi Company as the inner layer plate, and paste a photoresist layer on the surface of the conductor layer 2 of the double-sided copper-clad laminate, using wet film coating or Dry film is pressed, then exposed and developed to realize the transfer of conductive patterns. Specifically, film exposure method or laser direct imaging method can be used, and then acidic etching potion or alkaline etching potion is used to remove the excess conductor layer 2, and peel off the covering on the target. The photoresist layer of the conductive circuit to complete the production of the conductive circuit;

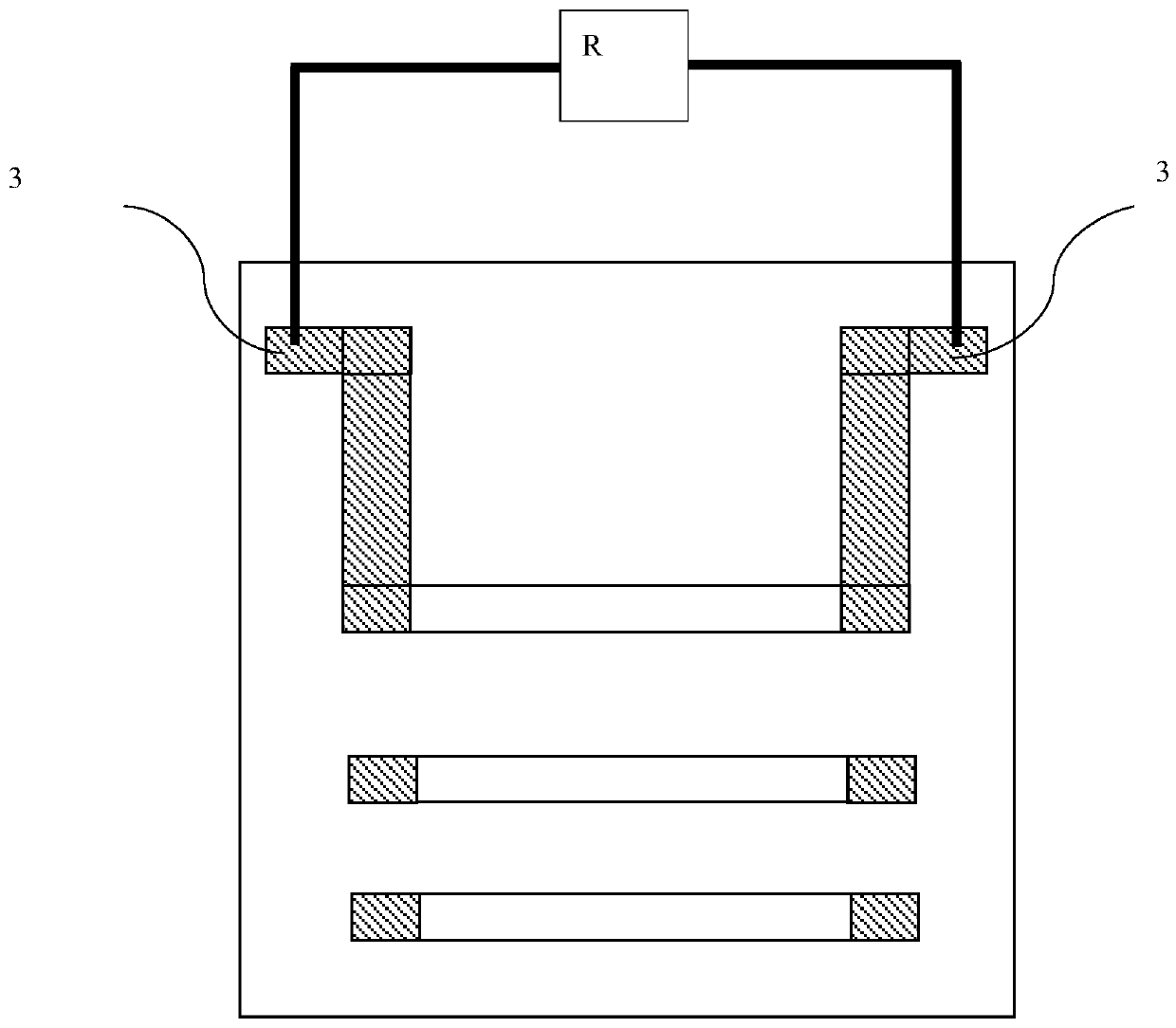

[0031] Step 2: Design of Em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com