A kind of polymer nanogel particle/calcium carbonate composite material and preparation method thereof

A technology of nanogel and composite materials, which is applied in the field of polymer nanogel particles/calcium carbonate composite materials and its preparation, can solve the problems of embedding calcium carbonate crystals and polymer nanogel particles, and achieve stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

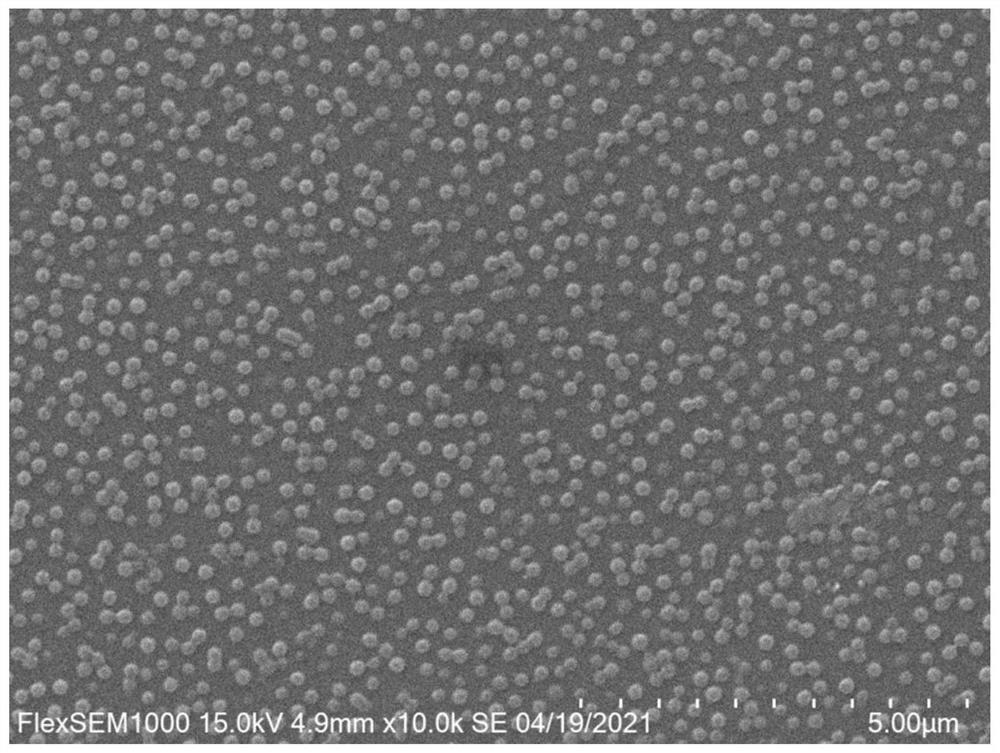

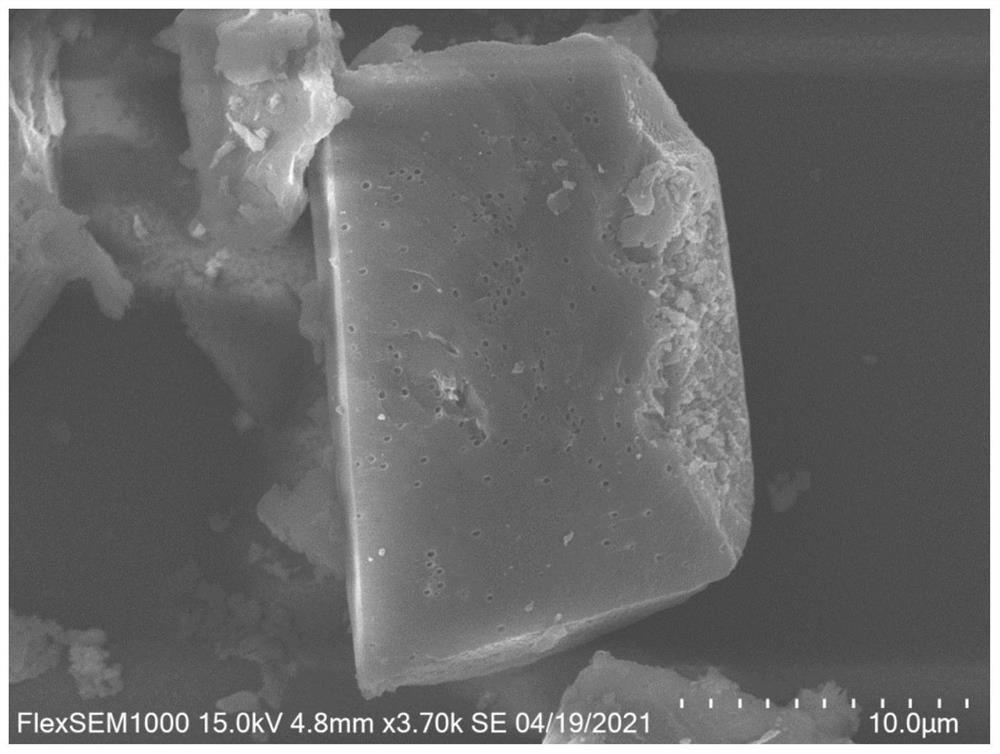

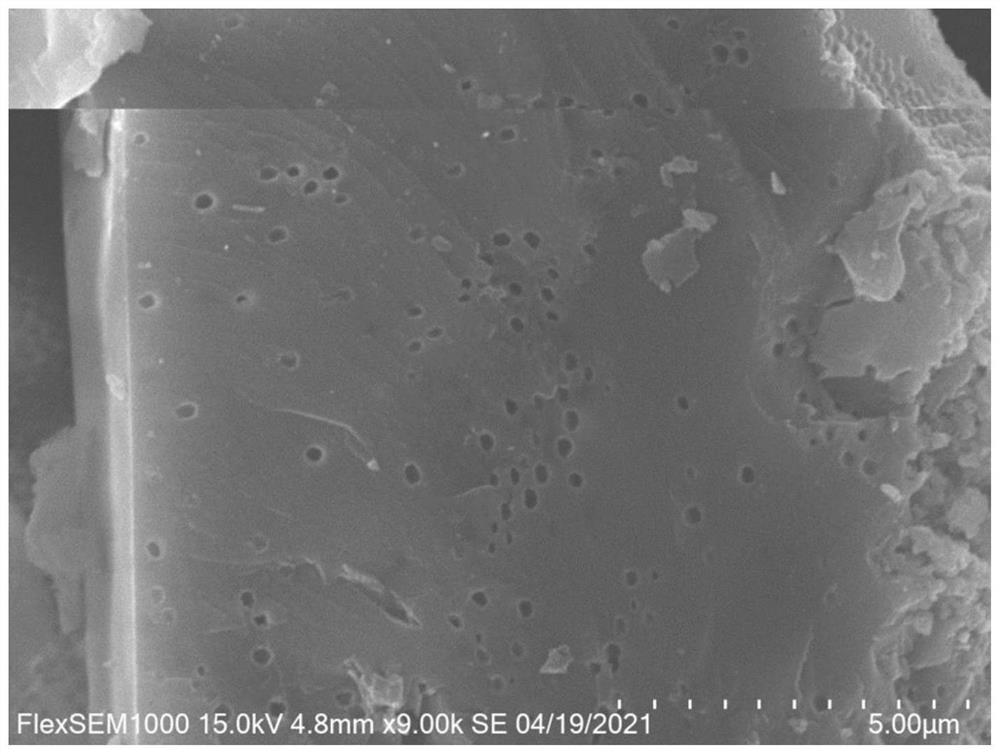

[0034] 0.8g of 2-(phosphonooxy)ethyl methacrylate, 0.8g of poly-N-vinylpyrrolidone (K60, 360000g / mol), 0.02g of azobisisobutyronitrile, 0.04g of di Add ethylene glycol methacrylate into a round-bottomed flask filled with 20 mL of methanol, blow nitrogen into an ice-water bath for 15 minutes to remove oxygen, place it in an oil bath at 60°C for 24 hours, and centrifuge 10 times with methanol to obtain the degree of crosslinking Be 5wt% (based on monomer) nanogel particle dispersion (nanogel particle scanning electron micrograph sees figure 1 ); prepare 10mL 1.5mM calcium chloride solution, add nanogel particle dispersion liquid wherein, make the nanogel particle dispersion liquid that contains 0.1wt% in the mixed system, carry out calcium carbonate crystal growth by ammonia diffusion method, obtain polymer Nanogel particle / calcium carbonate composite material (scanning electron micrograph sees figure 2 and image 3 ).

Embodiment 2

[0036] 0.8g of 2-(phosphonooxy)ethyl methacrylate, 0.8g of poly-N-vinylpyrrolidone (K60, 360000g / mol), 0.02g of azobisisobutyronitrile, 0.04g of di Add ethylene glycol methacrylate into a round-bottomed flask containing 20mL of methanol, blow nitrogen into an ice-water bath for 10min to remove oxygen, place it in an oil bath at 50°C for 36h, and centrifuge 8 times with methanol to obtain the degree of crosslinking Be the nanogel particle dispersion liquid of 5wt% (based on monomer); Prepare 10mL 1.5mM calcium chloride solution, add nanogel particle dispersion liquid thereinto, make the nanogel particle dispersion liquid containing 0.02wt% in the mixing system , calcium carbonate crystal growth by ammonia diffusion method to obtain polymer nanogel particles / calcium carbonate composites.

Embodiment 3

[0038]0.8g of 2-(phosphonooxy)ethyl methacrylate, 0.8g of poly-N-vinylpyrrolidone (K60, 360000g / mol), 0.02g of azobisisobutyronitrile, 0.04g of di Add ethylene glycol methacrylate into a round-bottomed flask filled with 20mL of methanol, blow nitrogen into an ice-water bath for 20min to remove oxygen, place it in an oil bath at 70°C for 12h, and centrifuge 10 times with methanol to obtain the degree of crosslinking Be the nanogel particle dispersion liquid of 5wt% (based on monomer); Prepare 10mL 30mM calcium chloride solution, add nanogel particle dispersion liquid wherein, make the nanogel particle dispersion liquid containing 2wt% in the mixing system, pass Calcium carbonate crystal growth was carried out by ammonia diffusion method to obtain polymer nanogel particle / calcium carbonate composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com