Permanent magnet synchronous motor deadbeat torque prediction control method

A permanent magnet synchronous motor, predictive control technology, applied in motor generator control, AC motor control, electronic commutation motor control and other directions, can solve the problems of complex algorithms and high requirements for digital controllers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

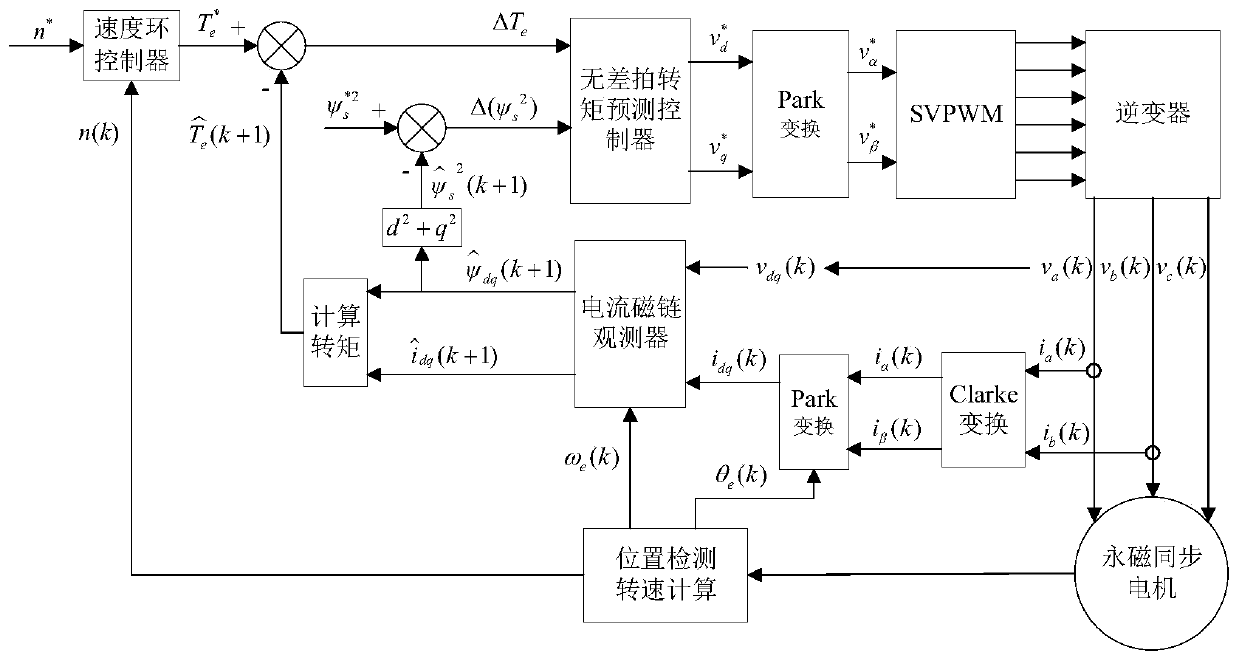

[0062] The key technologies and specific implementation methods in the present invention will be described in detail below in conjunction with the drawings and specific embodiments.

[0063] A deadbeat torque prediction control method for a permanent magnet synchronous motor of the present invention, comprising the following steps:

[0064] 1. Define f dq =f d +j·f q , where j is an imaginary number unit, f can represent voltage v, current i and flux linkage ψ, the purpose is to use a single variable f dq conveniently expresses f d and f q .

[0065] 2. Obtain the phase current, phase voltage, and speed signal of the motor at the current sampling time (k time) (the actual speed of the rotor n(k) and the electrical angular velocity ω e (k)) and rotor position (θ e (k)), the phase voltage is more complex due to direct measurement, and generally can be directly calculated according to the control signal; the current of the motor in the synchronous rotating coordinate syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com