High-strength and high-manganese steel having excellent low-temperature toughness and manufacturing method therefor

A low-temperature toughness and high-strength technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of high Ni price and easy volatility, and achieve high-strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0096] Hereinafter, the present disclosure will be described more specifically according to an embodiment. However, the following examples should be considered in a descriptive sense only and not for purposes of limitation. The scope of the present disclosure is defined by the appended claims and modifications and variations therefrom may be reasonably made.

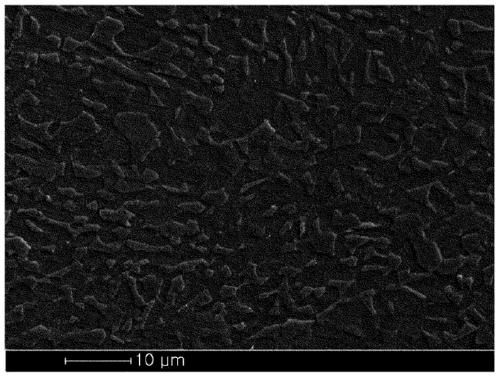

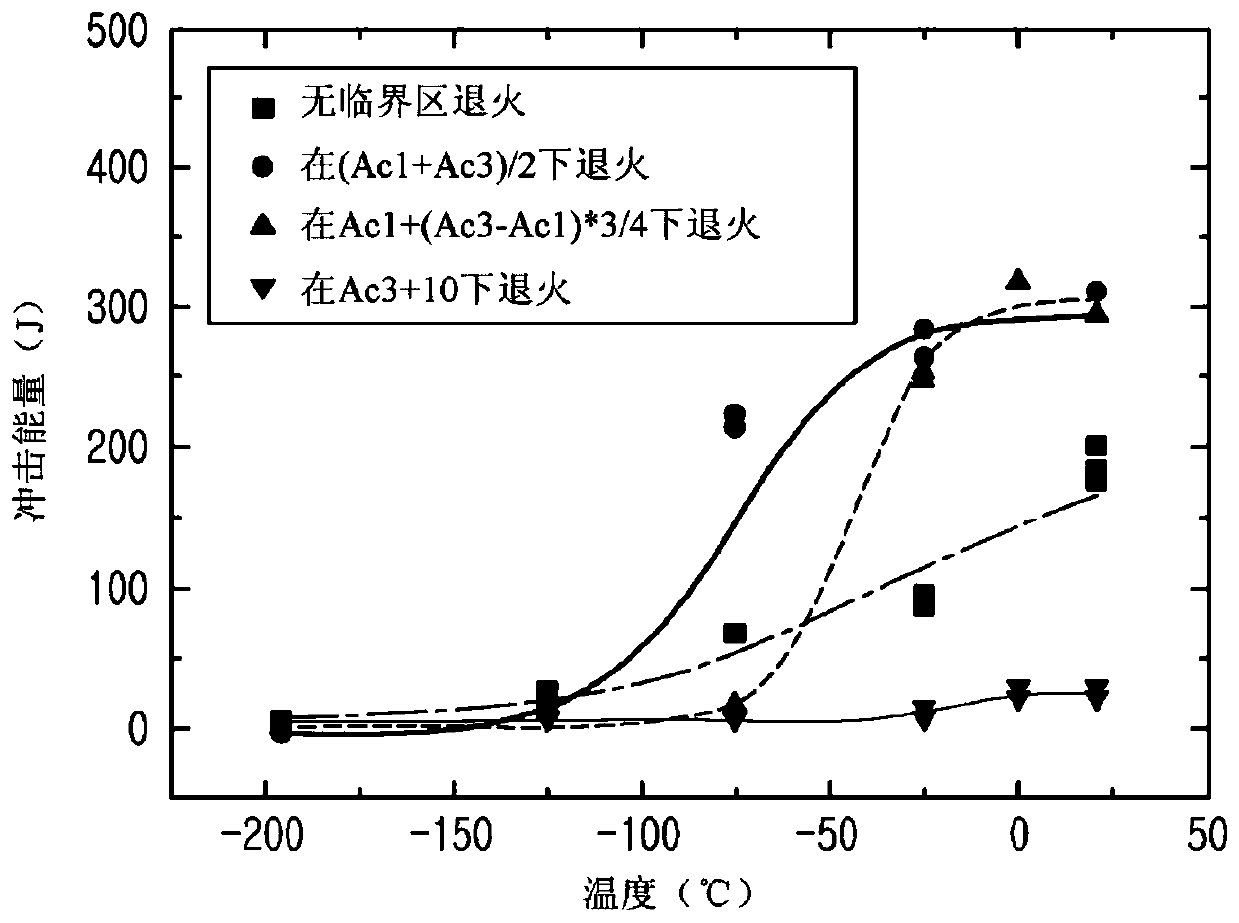

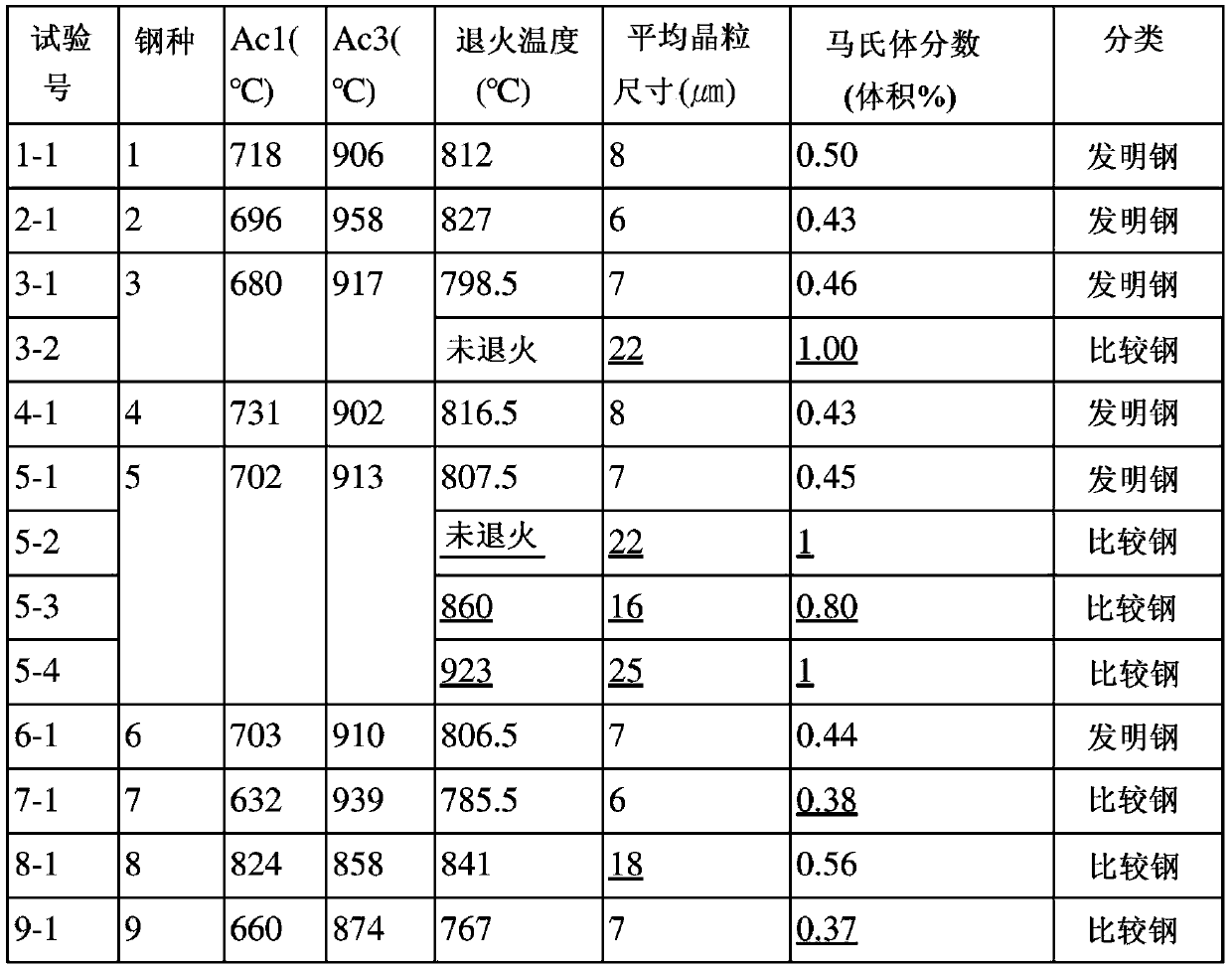

[0097] A slab having a thickness of 70 mm and having the composition shown in Table (1) below was heated to 1100° C. and then subjected to final hot rolling at a final hot rolling temperature of 800° C. to obtain a hot-rolled steel sheet with a thickness of 11.8 mm. After cooling at a cooling rate of 10°C / sec in the temperature range from Ar3 to 200°C, the hot-rolled steel sheet was heated to the annealing temperature described in Table 2, and then cooled to produce high manganese steel.

[0098] The microstructure of the high manganese steel was observed and shown in Table (2) below. The mechanical properties of the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com