Processing equipment for negative oxygen ion novel material decorative-surface artificial board and processing method

A technology of negative oxygen ions and processing equipment, which is applied in wood processing equipment, manufacturing tools, wood treatment, etc., can solve the problems of negative oxygen ions not up to standard, achieve the effect of reducing the amount of formaldehyde released and preventing mold and bacteria from breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

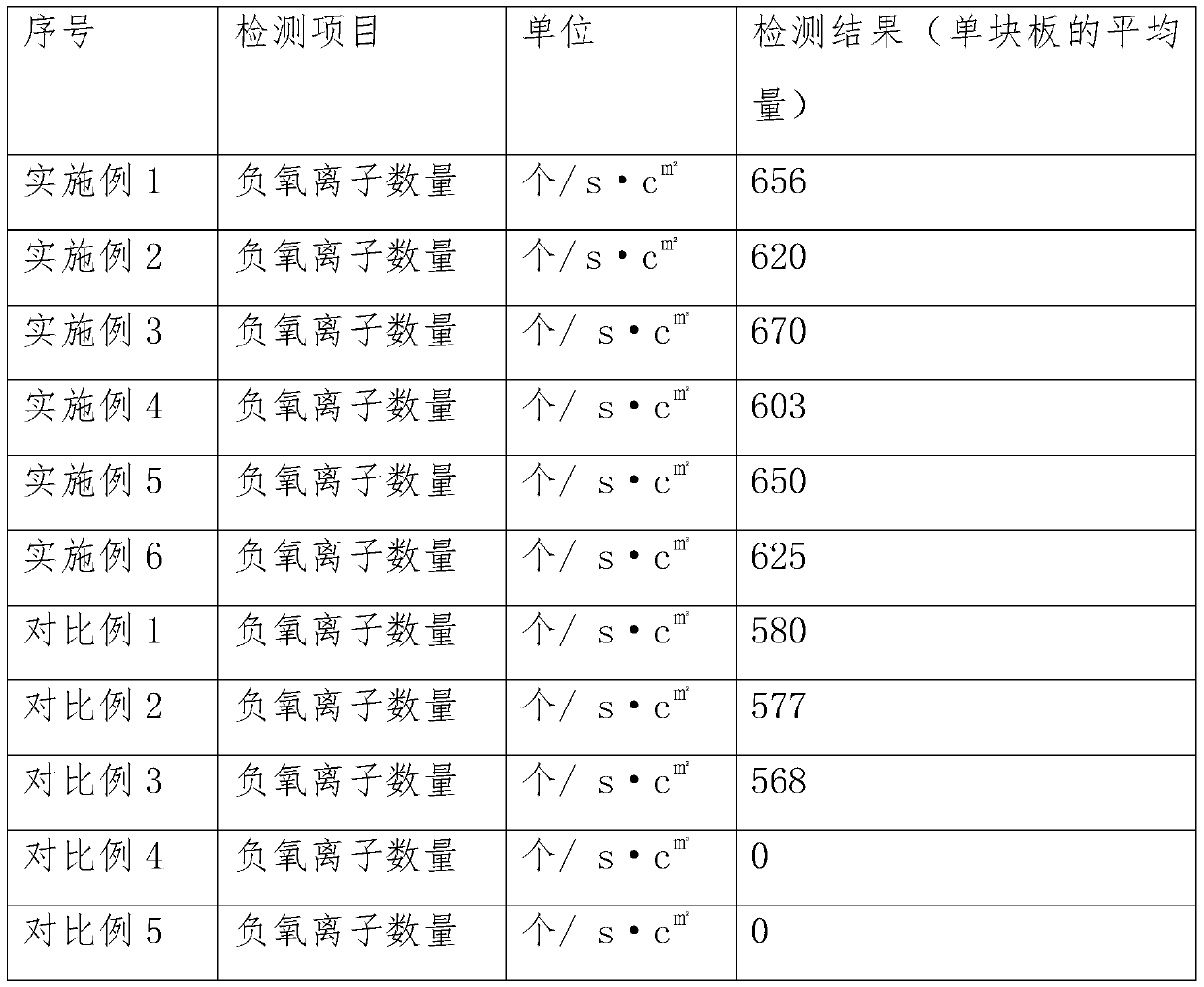

Embodiment 1

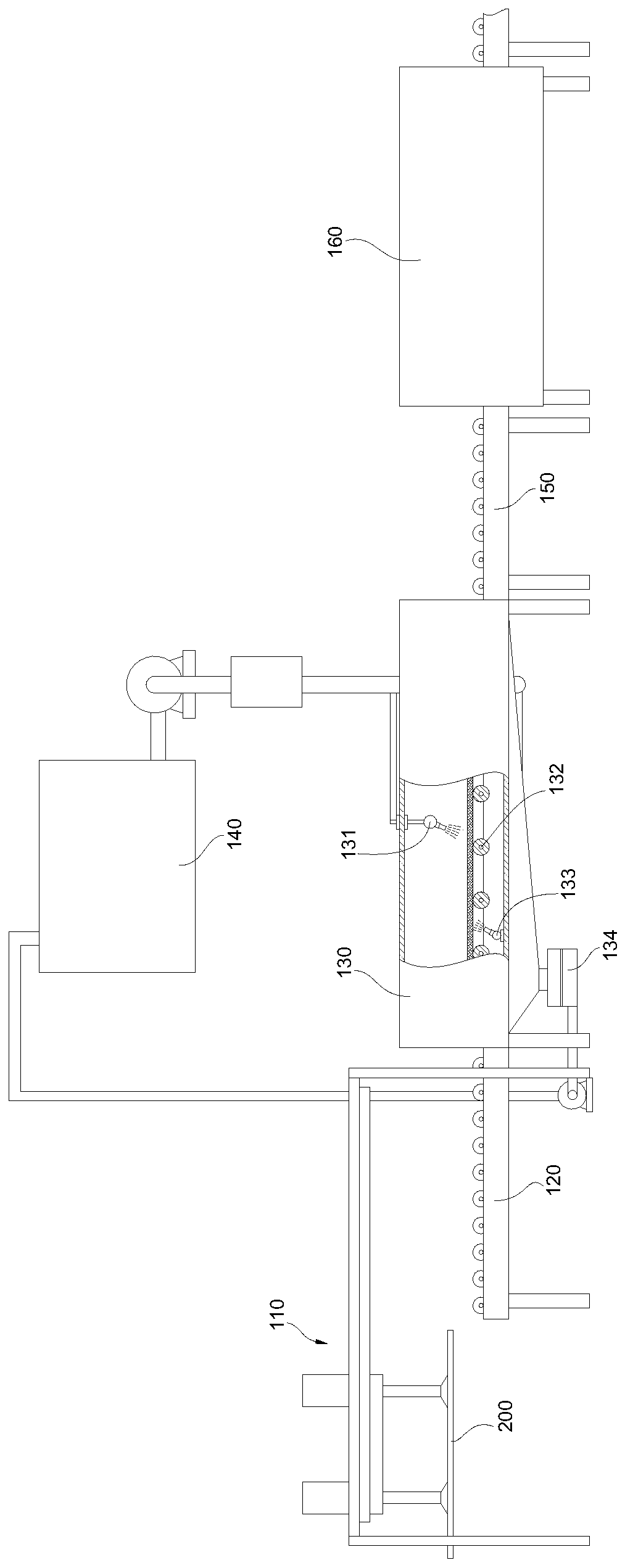

[0070] S1: the grabbing mechanism 110 grabs the substrate and moves it to the first conveying roller 120;

[0071] S2: The first conveying roller 120 moves the substrate to the negative oxygen ion liquid spraying device 130;

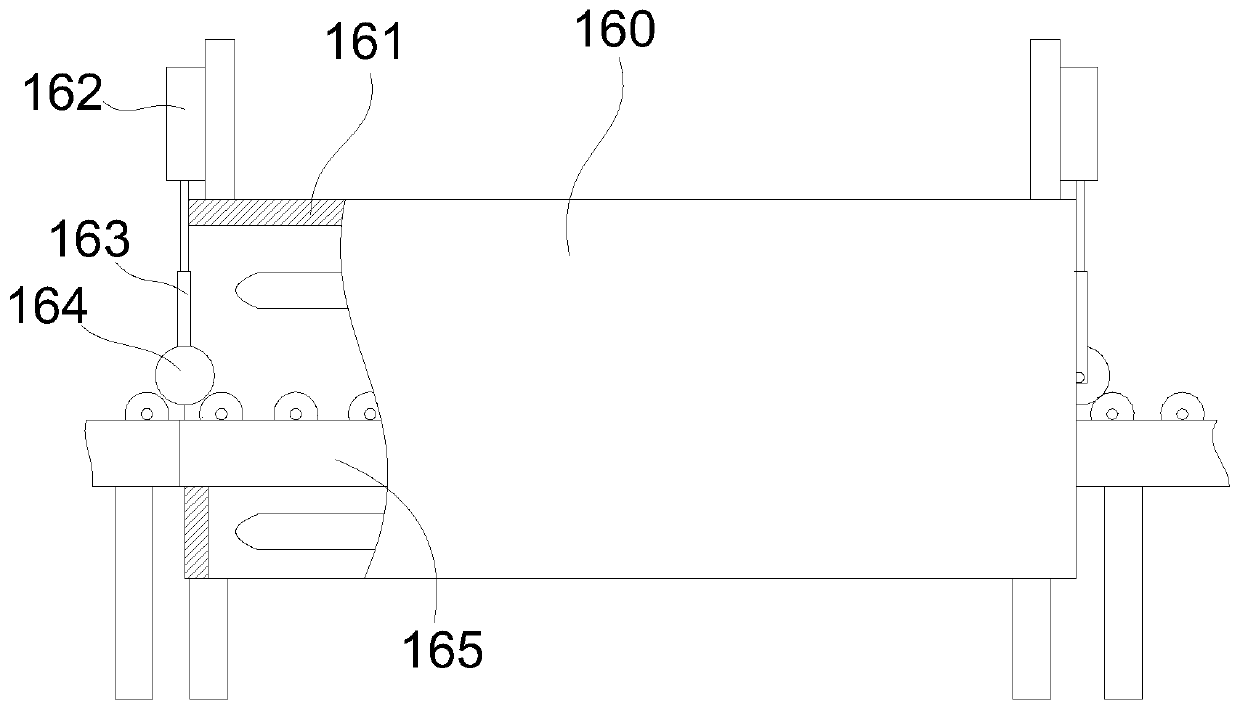

[0072] S3: Negative oxygen ionic liquid is contained in the negative oxygen ionic liquid storage box 140, and the negative oxygen ionic liquid is supplied to the negative oxygen ionic liquid spraying device 130. In the negative oxygen ionic liquid spraying device 130, the spraying conveying roller 132 drives the substrate to move at a constant speed The upper spraying mechanism 131 sprays the negative oxygen ion liquid on the upper surface of the substrate, and the lower spraying mechanism 133 sprays the negative oxygen ion liquid on the lower surface of the substrate. After the substrate is completely sprayed, remove the negative oxygen ion liquid spraying device 130, Enter the second conveyor roller 150;

[0073] Wherein, the composition of the negati...

Embodiment 2

[0078] S1: the grabbing mechanism 110 grabs the substrate and moves it to the first conveying roller 120;

[0079] S2: The first conveying roller 120 moves the substrate to the negative oxygen ion liquid spraying device 130;

[0080] S3: Negative oxygen ionic liquid is contained in the negative oxygen ionic liquid storage box 140, and the negative oxygen ionic liquid is supplied to the negative oxygen ionic liquid spraying device 130. In the negative oxygen ionic liquid spraying device 130, the spraying conveying roller 132 drives the substrate to move at a constant speed The upper spraying mechanism 131 sprays the negative oxygen ion liquid on the upper surface of the substrate, and the lower spraying mechanism 133 sprays the negative oxygen ion liquid on the lower surface of the substrate. After the substrate is completely sprayed, remove the negative oxygen ion liquid spraying device 130, Enter the second conveyor roller 150;

[0081] Wherein, the composition of the negati...

Embodiment 3

[0086] S1: the grabbing mechanism 110 grabs the substrate and moves it to the first conveying roller 120;

[0087] S2: The first conveying roller 120 moves the substrate to the negative oxygen ion liquid spraying device 130;

[0088] S3: Negative oxygen ionic liquid is contained in the negative oxygen ionic liquid storage box 140, and the negative oxygen ionic liquid is supplied to the negative oxygen ionic liquid spraying device 130. In the negative oxygen ionic liquid spraying device 130, the spraying conveying roller 132 drives the substrate to move at a constant speed The upper spraying mechanism 131 sprays the negative oxygen ion liquid on the upper surface of the substrate, and the lower spraying mechanism 133 sprays the negative oxygen ion liquid on the lower surface of the substrate. After the substrate is completely sprayed, remove the negative oxygen ion liquid spraying device 130, Enter the second conveyor roller 150;

[0089] Wherein, the composition of the negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com