ZnO voltage-sensitive ceramic with high electric potential gradient and preparation method of ZnO voltage-sensitive ceramic

A pressure-sensitive ceramic and high-potential technology, applied in the field of pressure-sensitive ceramics, can solve the problems of high energy consumption, difficult to meet the requirements of miniaturization of power electronic devices, complicated preparation process, etc., and achieve the effect of reducing the sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

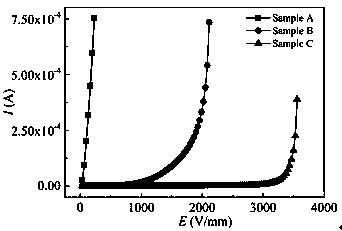

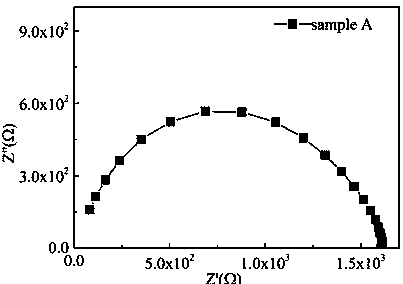

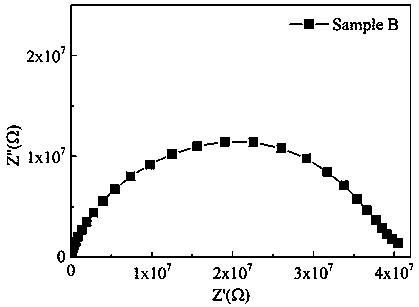

[0026] Embodiment 1: A method for preparing high potential gradient ZnO varistor ceramics, including the following steps:

[0027] S1: The high potential gradient ZnO varistor ceramic includes ZnO and metal oxide; the metal oxide is Bi 2 O 3 , CoO and Mn 2 O 3 , The ZnO, Bi 2 O 3 , CoO and Mn 2 O 3 The molar ratio of mixing is 98.5 mol%, 0.5 mol%, 0.5 mol%, 0.5 mol%, respectively;

[0028] Wet ball milling with alcohol as the medium after the aforementioned ingredients;

[0029] S2: After 24 hours of wet ball milling, the mixed powder is heated to 80 o C drying for 12h;

[0030] S3: Take the mixed powder after drying in S2, add dropwise 2mol / L of acetic acid, the acetic acid drop mass is 20% of the mass of the mixed powder after drying in S2, grind and mix in a mortar for 5 minutes, and then load the metal The mold uses an ordinary manual press to press 300MPa while heating the metal mold at a rate of 20 o C / min, up to 300 o C, at 300 o C heat preservation and sintering for 1 hour, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com