Method for preparing Hypsizygus marmoreus polysaccharide chelated selenium

A technology of seafood mushroom polysaccharides and seafood mushrooms, which is applied in the direction of drug combination, anti-virus, etc., to achieve the effect of enhanced scavenging ability and high chelation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

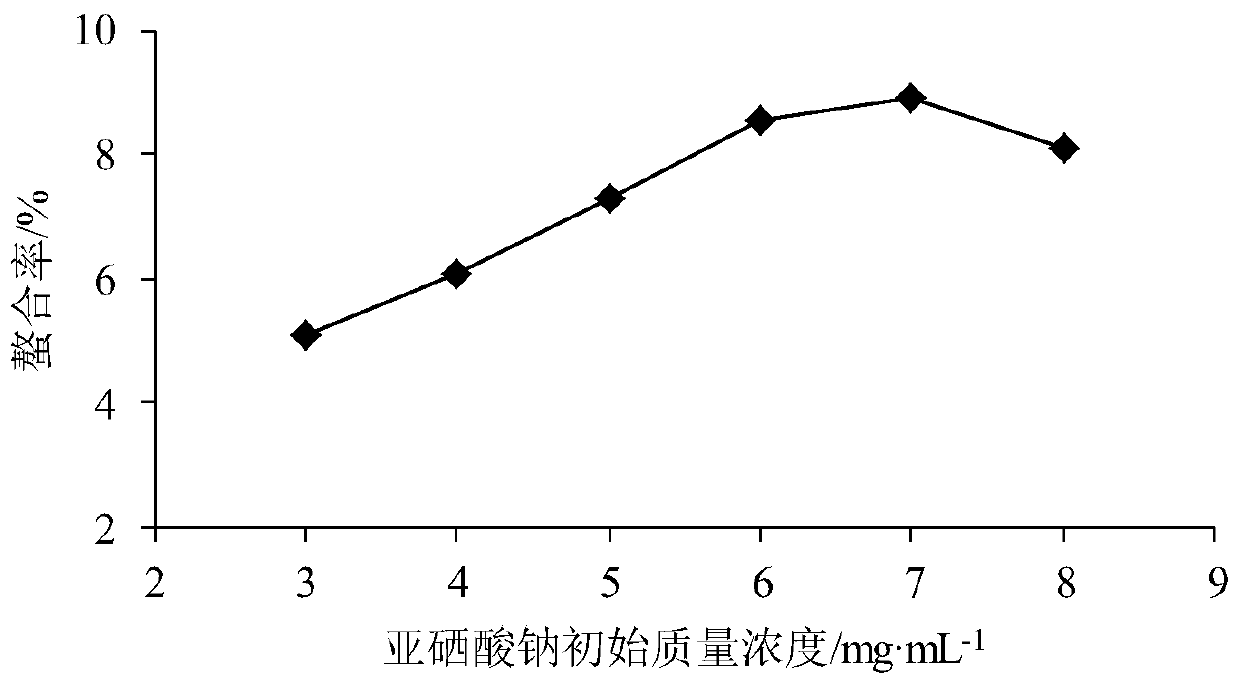

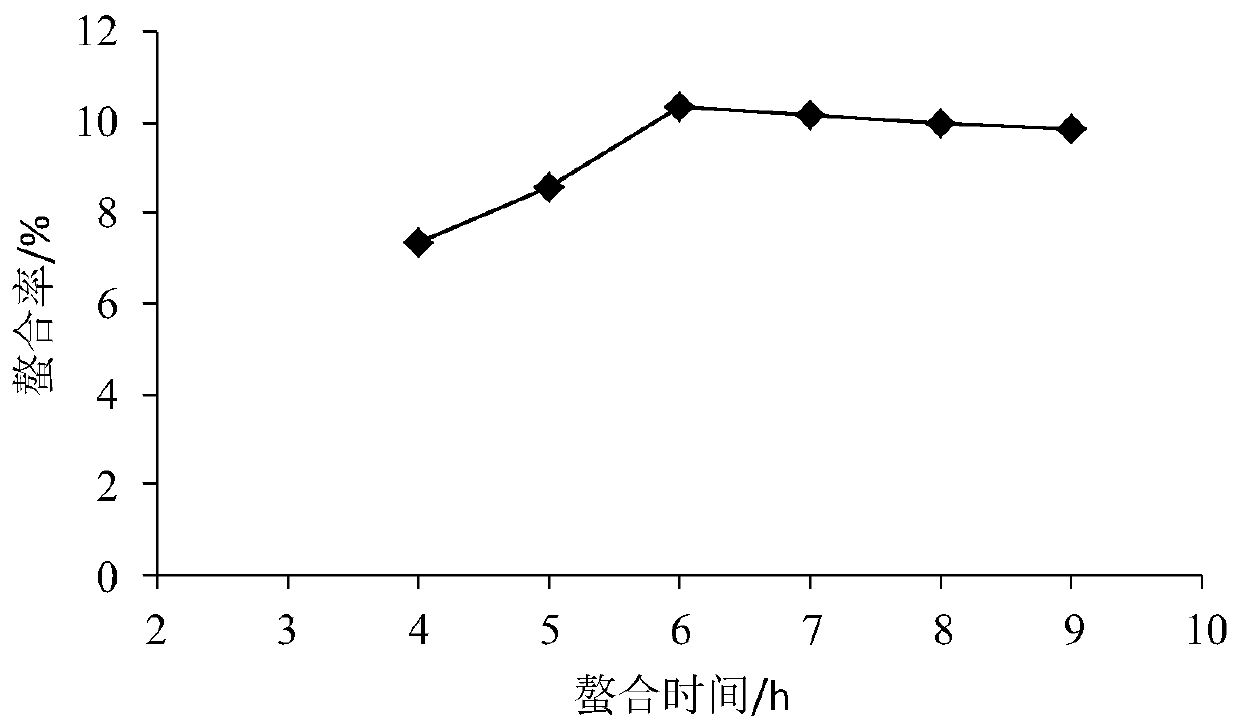

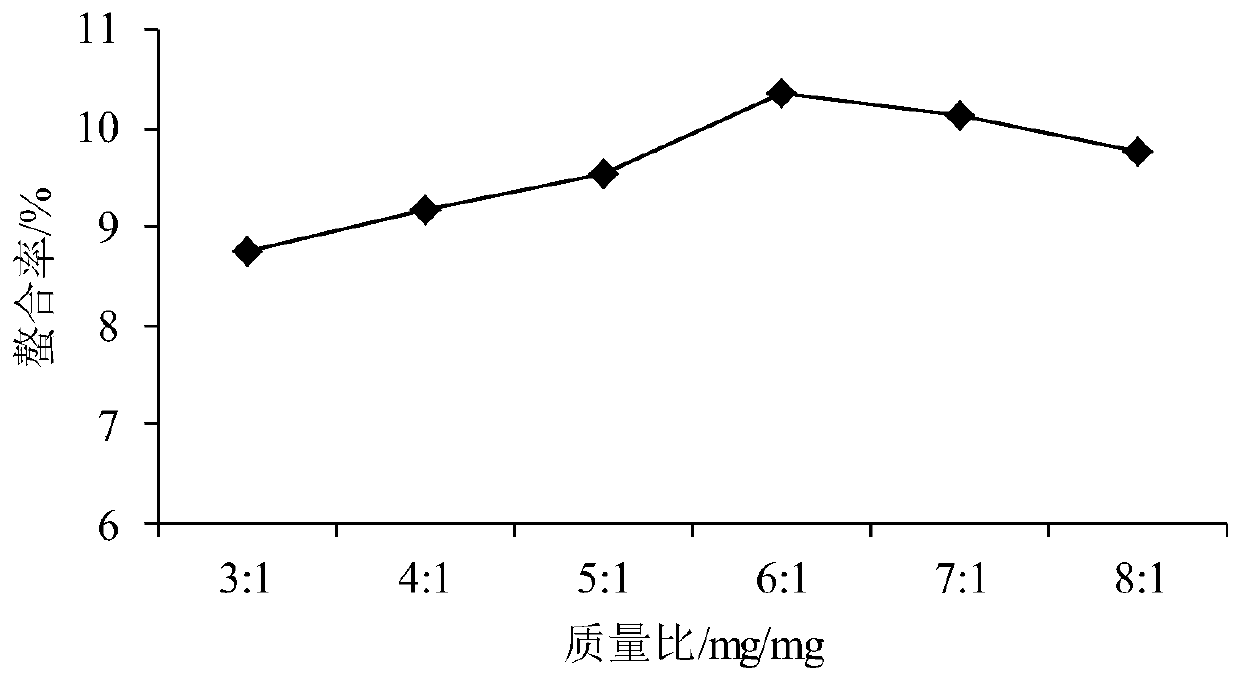

Method used

Image

Examples

Embodiment 1

[0050] Remove impurities, dry, and pulverize the seafood mushroom, and pass through a 60-mesh sieve to obtain dried seafood mushroom powder; weigh the dried seafood mushroom powder in a beaker, and use hot water extraction method: add deionized water according to the material-to-liquid ratio of 1:20, Put it in a 90°C water bath for 2 hours, stir continuously, and repeat the above process 3 times; centrifuge the obtained seafood mushroom polysaccharide filtrate for 15 minutes at a speed of 4000r / min. The solution was then concentrated at 70°C for 3 hours, and the protein in the polysaccharide concentrated solution was removed by sevage method, and the supernatant was collected after centrifugation; finally, 3 times the volume of 85% ethanol was slowly added to the solution for 12 hours to precipitate the polysaccharide gradually, and the solution was After centrifugation (centrifugation for 20 min at a centrifugal speed of 4000 r / min), the precipitates in the centrifuge tubes we...

Embodiment 2

[0054] Remove impurities, dry, and pulverize the seafood mushroom, and pass through a 60-mesh sieve to obtain dried seafood mushroom powder; weigh the dried seafood mushroom powder in a beaker, and use hot water extraction method: add deionized water according to the material-to-liquid ratio of 1:20, Put it in a 90°C water bath for 2 hours, stir continuously, and repeat the above process 3 times; centrifuge the obtained seafood mushroom polysaccharide filtrate for 15 minutes at a speed of 4000r / min. The solution was then concentrated at 70°C for 3 hours, and the protein in the polysaccharide concentrated solution was removed by sevage method, and the supernatant was collected after centrifugation; finally, 3 times the volume of 85% ethanol was slowly added to the solution for 12 hours to precipitate the polysaccharide gradually, and the solution was After centrifugation (centrifugation for 20 min at a centrifugal speed of 4000 r / min), the precipitates in the centrifuge tubes we...

Embodiment 3

[0058] Remove impurities, dry, and pulverize the seafood mushroom, and pass through a 60-mesh sieve to obtain dried seafood mushroom powder; weigh the dried seafood mushroom powder in a beaker, and use hot water extraction method: add deionized water according to the material-to-liquid ratio of 1:20, Put it in a 90°C water bath for 2 hours, stir continuously, and repeat the above process 3 times; centrifuge the obtained seafood mushroom polysaccharide filtrate for 15 minutes at a speed of 4000r / min. The solution was then concentrated at 70°C for 3 hours, and the protein in the polysaccharide concentrated solution was removed by sevage method, and the supernatant was collected after centrifugation; finally, 3 times the volume of 85% ethanol was slowly added to the solution for 12 hours to precipitate the polysaccharide gradually, and the solution was After centrifugation (centrifugation for 20 min at a centrifugal speed of 4000 r / min), the precipitates in the centrifuge tubes we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com