Coating-type flexible glue for veneer, and preparation method and implementation process of coating-type flexible glue

A coating-type, flexible technology, applied in the field of veneer treatment, can solve the problems of thin veneer substrate being brittle and easy to break, taking a lot of time, cracking, etc., to achieve the effect of protecting the veneer surface, saving production costs, and low odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

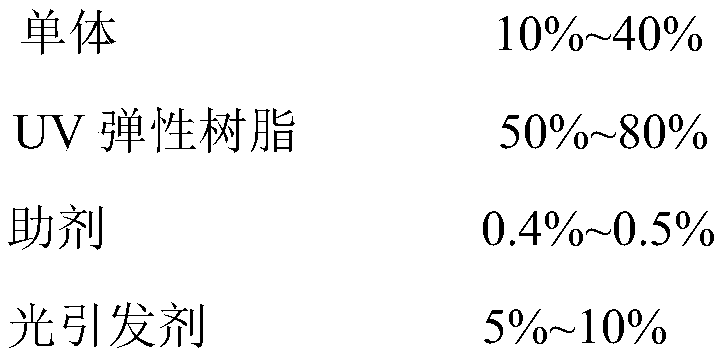

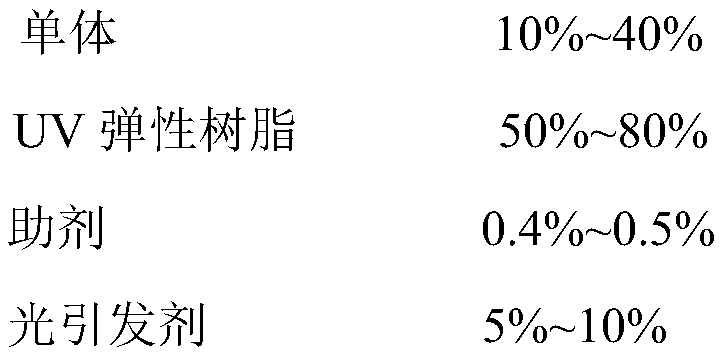

Method used

Image

Examples

Embodiment 1

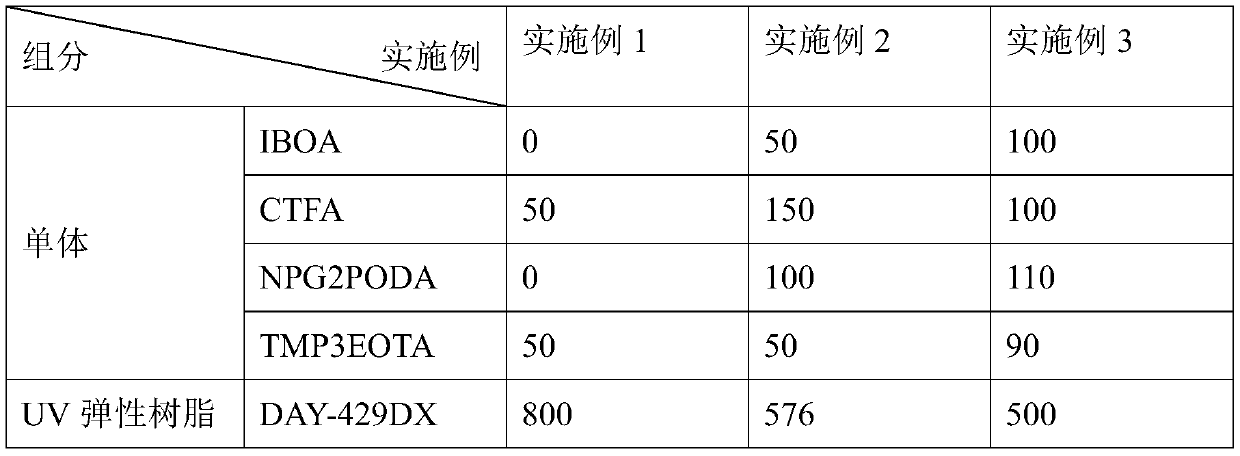

[0031] (1) A coating type flexible glue for veneer, with a weight of 1000kg, the dosage of each component is: IBOA is 0kg, CTFA is 50kg, NPG2PODA is 0kg, TMP3EOTA is 50kg, UV elastic resin is 800kg, dispersant 1kg, defoamer 1kg, leveling agent 3kg, photoinitiator HR184 80kg, photoinitiator BP 15kg.

[0032] (2) The preparation method of coating type flexible glue for thin veneer, its steps are as follows in order: the monomer and UV elastic resin are added in the dispersing tank, and it is 1000 rev / min to stir 10 with paddle mixer with rotating speed minute;

[0033] Add each component in the auxiliary agent successively, and stir for 10 minutes with a paddle mixer at a speed of 1000 rpm; add the photoinitiator, and stir for 10 minutes with a paddle mixer at 1500 rpm;

[0034] After ultrasonication, the coating-type flexible glue for veneer is obtained.

[0035] (3) A kind of implementation process of coating type flexible glue for thin veneer, its steps are as follows in se...

Embodiment 2

[0040] (1) A coating type flexible glue for veneer, with a weight of 1000kg, the dosage of each component is: IBOA is 50kg, CTFA is 150kg, NPG2PODA is 100kg, TMP3EOTA is 50kg, UV elastic resin is 576kg, dispersant 1kg, defoamer 2kg, leveling agent 1kg, photoinitiator HR184 55kg, photoinitiator BP 15kg.

[0041] (2) The preparation method of coating type flexible glue for thin veneer, its steps are as follows in order: the monomer and UV elastic resin are added in the dispersion tank, and it is 1200 rev / min to stir 15 with the paddle type mixer with the rotating speed minute;

[0042] Add the ingredients in the auxiliary agent successively, and stir for 15 minutes at 1300 rpm with a paddle mixer at a speed of 15 minutes; Add the photoinitiator, and stir with a paddle mixer at 1300 rpm for 15 minutes;

[0043] After ultrasonication, the coating-type flexible glue for veneer is obtained.

[0044] (3) A kind of implementation process of coating type flexible glue for thin veneer...

Embodiment 3

[0049](1) A coating type flexible glue for veneer, with a weight of 1000kg, the dosage of each component is: IBOA is 100kg, CTFA is 100kg, NPG2PODA is 110kg, TMP3EOTA is 90kg, UV elastic resin is 500kg, dispersant 2kg, defoamer 2kg, leveling agent 1kg, photoinitiator HR184 60kg, photoinitiator BP 35kg.

[0050] (2) The preparation method of coating type flexible glue for thin veneer, its steps are as follows in order: the monomer and UV elastic resin are added in the dispersing tank, and it is 1500 rev / min to stir 20 with paddle type mixer with rotating speed minute;

[0051] Add each component in the auxiliary agent successively, stir 20 minutes at 1500 rpm with a paddle mixer at a rotating speed; Add the photoinitiator, stir with a paddle mixer at 2000 rpm for 20 minutes;

[0052] After ultrasonication, the coating-type flexible glue for veneer is obtained.

[0053] (3) A kind of implementation process of coating type flexible glue for thin veneer, its steps are as follows...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com