A kind of thin film growth system and growth method

A thin-film growth and thin-film technology, applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of unusable thin film, sample contamination, insufficient growth of crystalline thin film, etc., to expand the scope of application, grow sufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

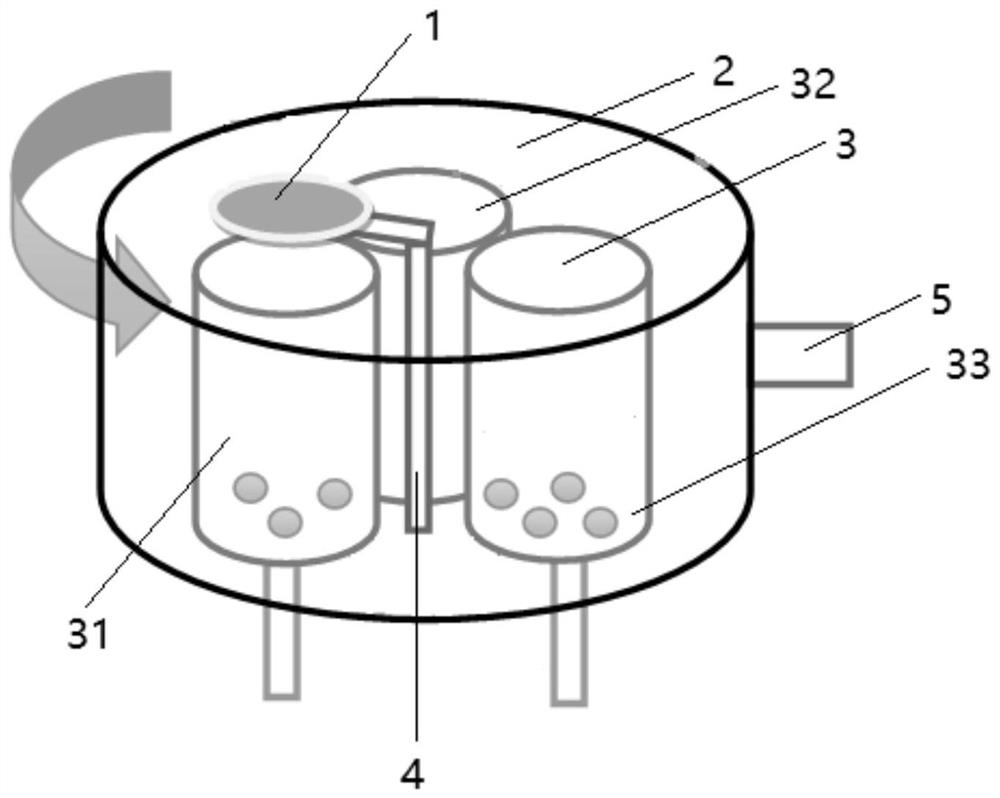

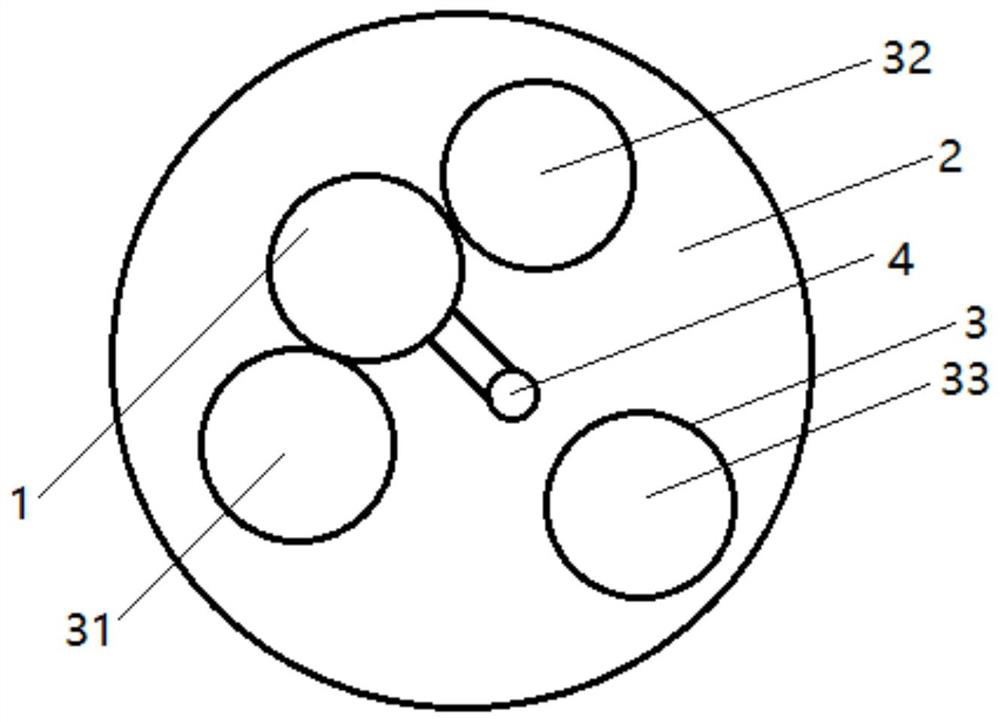

[0047] A thin film growth system, comprising a sample chamber, a large chamber, a plurality of small chambers, and a central axis, the plurality of small chambers are located in the large chamber, and the central axis is located in the center of the axis of the large chamber, The sample chamber is connected to the central shaft through a cross bar, and is used to transfer the sample in the sample chamber, and the transfer of the sample includes transferring between the plurality of small chambers, and / or, in the Transfer between the small chamber and the large chamber; the plurality of small chambers include a first small chamber and a second small chamber and an annealing chamber, and the first small chamber and the second small chamber The bottom of the chamber is provided with an openable and closable through hole, which is used to feed the precursor.

[0048] Specifically, in order to transfer the sample in the sample chamber between a plurality of small chambers, the radi...

Embodiment 2

[0050] S1. Start the vacuum pump, put the large chamber and the annealing chamber in a vacuum state, heat the small chamber so that the temperature of the first small chamber is 100°C, the temperature of the second small chamber is 300°C, and the annealing chamber The temperature is 800°C;

[0051] S2. Place the sample chamber in the first small chamber, put the silicon wafer into the sample chamber, and fill the first small chamber with the precursor trimethylaluminum, so that the silicon wafer is placed in the precursor trimethylaluminum Carry out saturated adsorption in the base aluminum to obtain the first sample;

[0052] S3. Transfer the sample chamber containing the first sample from the first small chamber to the large chamber through the central shaft, and blow nitrogen gas into the large chamber for purging, the During the purging process, the vacuum pump discharges the nitrogen gas to obtain a second sample;

[0053] S4. Transfer the sample chamber containing the ...

Embodiment 3

[0058] S1. Start the vacuum pump to make the large chamber and the annealing chamber in a vacuum state, heat the small chamber so that the temperature of the first small chamber is 80°C, the temperature of the second small chamber is 130°C, and the annealing chamber The temperature is 500°C;

[0059] S2. Place the sample chamber in the first small chamber, put quartz glass into the sample chamber, and fill the first small chamber with the precursor copper hexafluoroacetylacetonate, so that the quartz glass is placed in the precursor six Copper fluoroacetylacetonate is subjected to saturated adsorption to obtain the first sample;

[0060] S3. Transfer the sample chamber containing the first sample from the first small chamber to the large chamber through the central axis, and blow argon gas into the large chamber for purging. During the purging process, the vacuum pump discharges the argon to obtain a second sample;

[0061] S4. Transfer the sample chamber containing the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com