Preparation method of polyurethane resin composite material for medical bandage coating

A technology of polyurethane resin and composite material, used in bandages, medical science, absorbent pads, etc., can solve the problems of poor air permeability of bandages, and achieve the effect of improving the comfort of use, balancing metabolism and blood circulation, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

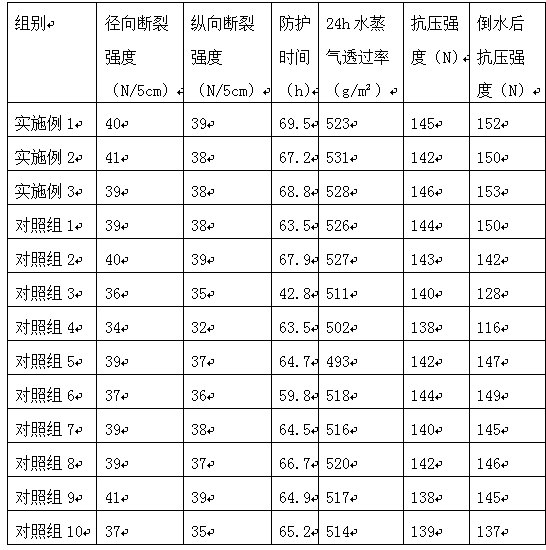

Examples

preparation example Construction

[0024] A preparation method of polyurethane resin composite material for medical bandage coating, comprising the following contents:

[0025] (1) Preparation of polyurethane prepolymer: raw materials in parts by weight, 80-100 parts of polyether diol, 12-16 parts of diisocyanate, 4-6 parts of tertiary vinyl carbonate, 1-2 parts of Nitrogen-containing organic base, 6-8 parts of bismorpholino diethyl ether, 1-2 parts of pentamethyldiethylenetriamine, stirred and reacted for 1-2 hours at a temperature of 85-90°C to obtain Polyurethane prepolymer;

[0026] (2) Preparation of polyurethane resin composite material: Raw materials are calculated in parts by weight, heat 100 parts of polyurethane prepolymer to 60-70°C, and add 12-16 parts of nano strontium-doped hydroxyapatite, 2- 3 parts of chitosan derivatives, 0.2-0.8 parts of S-methylisothiourea sulfate, 0.2-0.8 parts of 2,2'-methylenebis(4-methyl-6-tert-butylphenol), stirring React for 2-3 hours to obtain the polyurethane resin ...

Embodiment 1

[0044] A preparation method of polyurethane resin composite material for medical bandage coating, comprising the following contents:

[0045] (1) Preparation of polyurethane prepolymer: raw materials in parts by weight, 90 parts of polyether N210, 14 parts of diisocyanate, 5 parts of tertiary vinyl carbonate, 1.5 parts of nitrogen-containing organic base, 7 parts of bismorpholine Base diethyl ether, 1.5 parts of pentamethyldiethylenetriamine, stirred and reacted for 1.5 hours at a temperature of 88 ° C to obtain a polyurethane prepolymer;

[0046] (2) Preparation of polyurethane resin composite material: Raw materials are calculated in parts by weight. Heat 100 parts of polyurethane prepolymer to 65 ° C. Under nitrogen atmosphere, add 14 parts of nano strontium-doped hydroxyapatite and 2.5 parts of p-hydroxybenzoic acid Chitosan ester, 0.5 part of S-methylisothiouronium sulfate, 0.5 part of 2,2'-methylenebis(4-methyl-6-tert-butylphenol), stirred for 2.5 hours to obtain polyure...

Embodiment 2

[0052] A preparation method of polyurethane resin composite material for medical bandage coating, comprising the following contents:

[0053] (1) Preparation of polyurethane prepolymer: raw materials in parts by weight, 80 parts of polyether N220, 16 parts of diisocyanate, 4 parts of tertiary vinyl carbonate, 2 parts of nitrogen-containing organic base, 6 parts of bismorpholine Base diethyl ether, 1 part of pentamethyldiethylenetriamine, stirred and reacted for 2 hours at a temperature of 85 ° C to obtain a polyurethane prepolymer;

[0054] (2) Preparation of polyurethane resin composite material: Raw materials in parts by weight, heat 100 parts of polyurethane prepolymer to 70°C, add 12 parts of nano strontium-doped hydroxyapatite, 3 parts of carboxymethyl shell polysaccharide, 0.2 part of S-methylisothiouronium sulfate, 0.8 part of 2,2'-methylenebis(4-methyl-6-tert-butylphenol), stirred and reacted for 3 hours to obtain polyurethane resin compound material;

[0055] The po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com