Preparation method of molecular chain soft segment flame retardant polyurethane foam

A polyurethane foam and molecular chain technology, applied in the field of flame retardant materials, can solve the problems of deterioration of mechanical properties of polyurethane foam, increase of brittleness of polyurethane foam, migration of flame retardants, etc., and achieve long-lasting flame retardant performance, excellent flame retardant performance, The effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

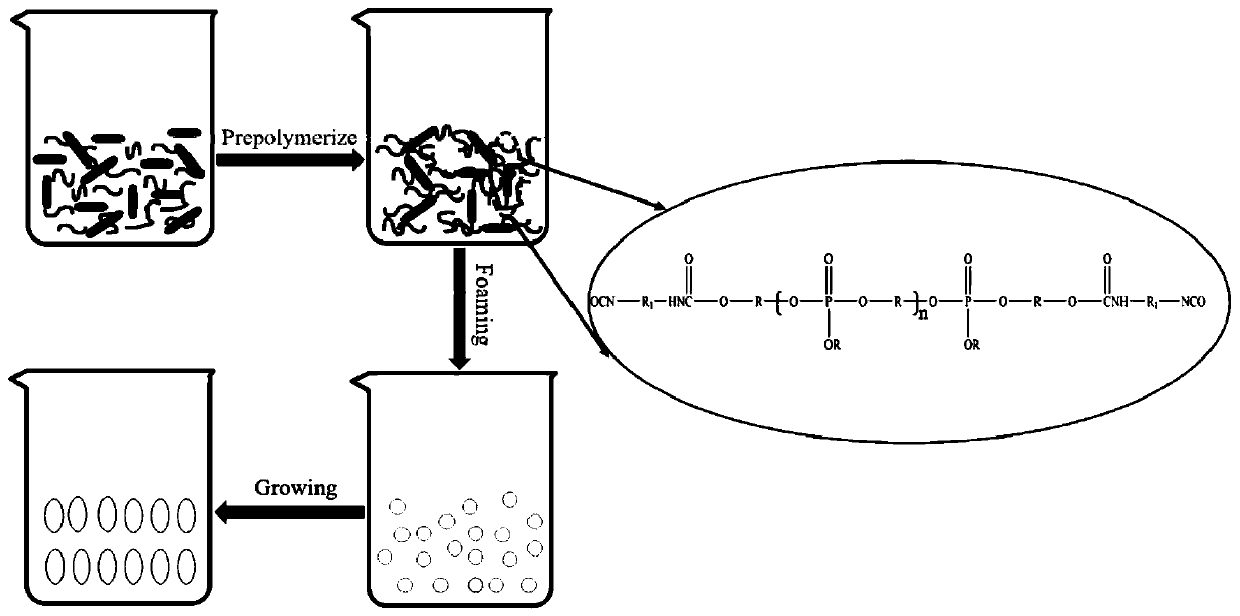

[0035] Embodiment 1~4, the preparation of soft segment flame-retardant polyurethane foam of the present invention

[0036] 1. Preparation of reactive liquid molecule HEP

[0037] Take dimethyl methyl phosphate and ethylene glycol with a molar ratio of 1:1, under the action of a catalytic amount of catalyst tetrabutyl titanate, react at 140°C for 5h to remove methanol, and then dehydrate under vacuum at 180°C for 3h to obtain Reactive liquid molecule HEP.

[0038] The synthetic route is as follows:

[0039]

[0040] Among them, n=10-15.

[0041] 2. Raw material ratio of the soft segment flame retardant polyurethane foam of the present invention

[0042] Table 1 The raw material ratio of the soft segment flame-retardant polyurethane foam of Examples 1 to 4 of the present invention

[0043]

[0044] In Table 1, the structural formula of polyether polyol is (Molecular weight is 4000, hydroxyl value is 27~29mgKOH / g); the structural formula of chain extender butanediol i...

PUM

| Property | Measurement | Unit |

|---|---|---|

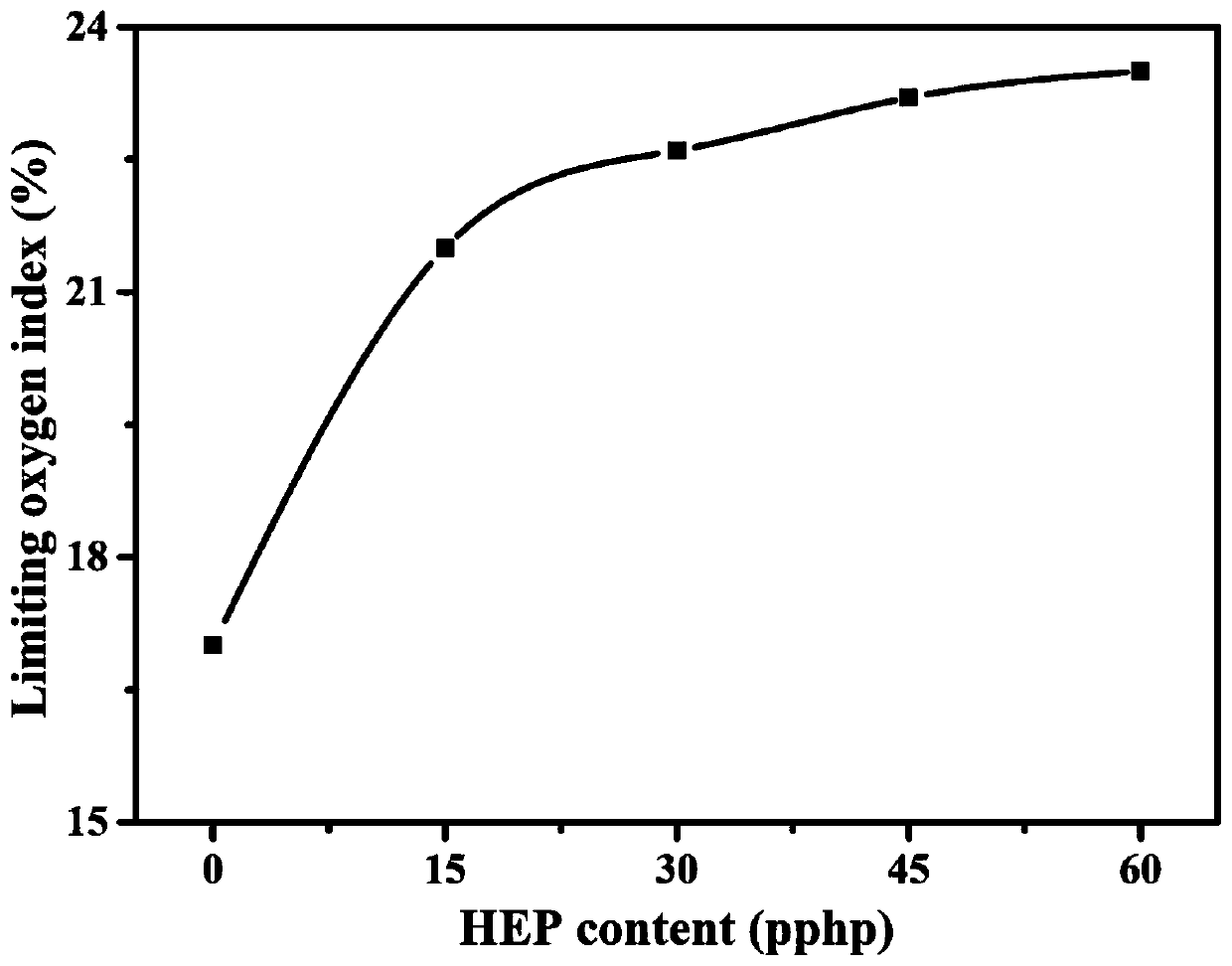

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com