Optical flow control cell sorting chip and method

A technology of optofluidics and cells, applied in the field of optofluidics, can solve the problems of high economic cost and time cost, difficult simultaneous manipulation and separation of cells, difficult microfluidic chip combination, etc., to achieve low cost of experimental equipment and enhanced application Field, mobility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

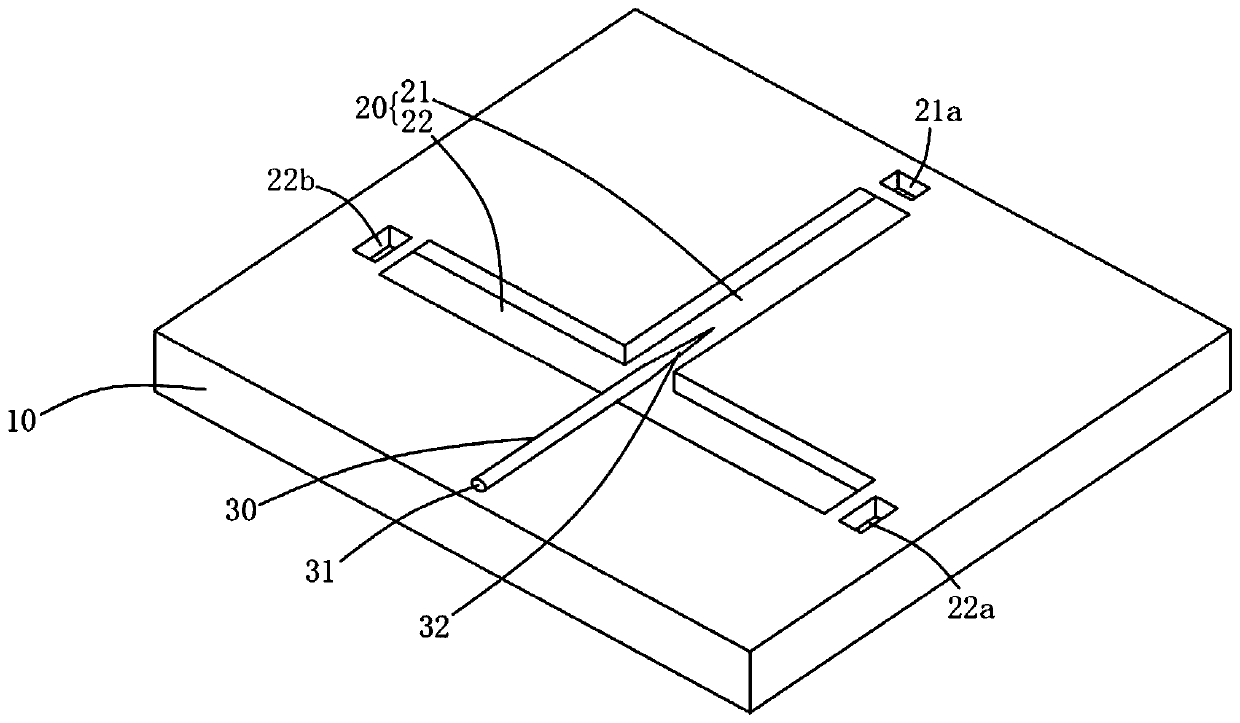

[0049] Such as figure 1As shown, the optofluidic cell sorting chip according to Embodiment 1 of the present invention includes a substrate 10, a microfluidic channel 20 and an optical waveguide 30, wherein the microfluidic channel 20 is arranged in the substrate 10, and the optical waveguide 30 is movably arranged in the on substrate 10. The microfluidic channel 20 at least includes a first channel 21 and a second channel 22 communicating with each other, the first channel 21 and the second channel 22 are both used to accommodate microfluids, and the first channel 21 is also used to accommodate at least two kinds of cells. The optical waveguide 30 includes an optical signal input end 31 and a capture end 32, the optical signal input end 31 is used for receiving an optical signal, the capture end 32 is used for adsorbing one of the at least two types of cells, and the capture end 32 is used for absorbing The cells move into the second channel 22. As a preferred embodiment, th...

Embodiment 2

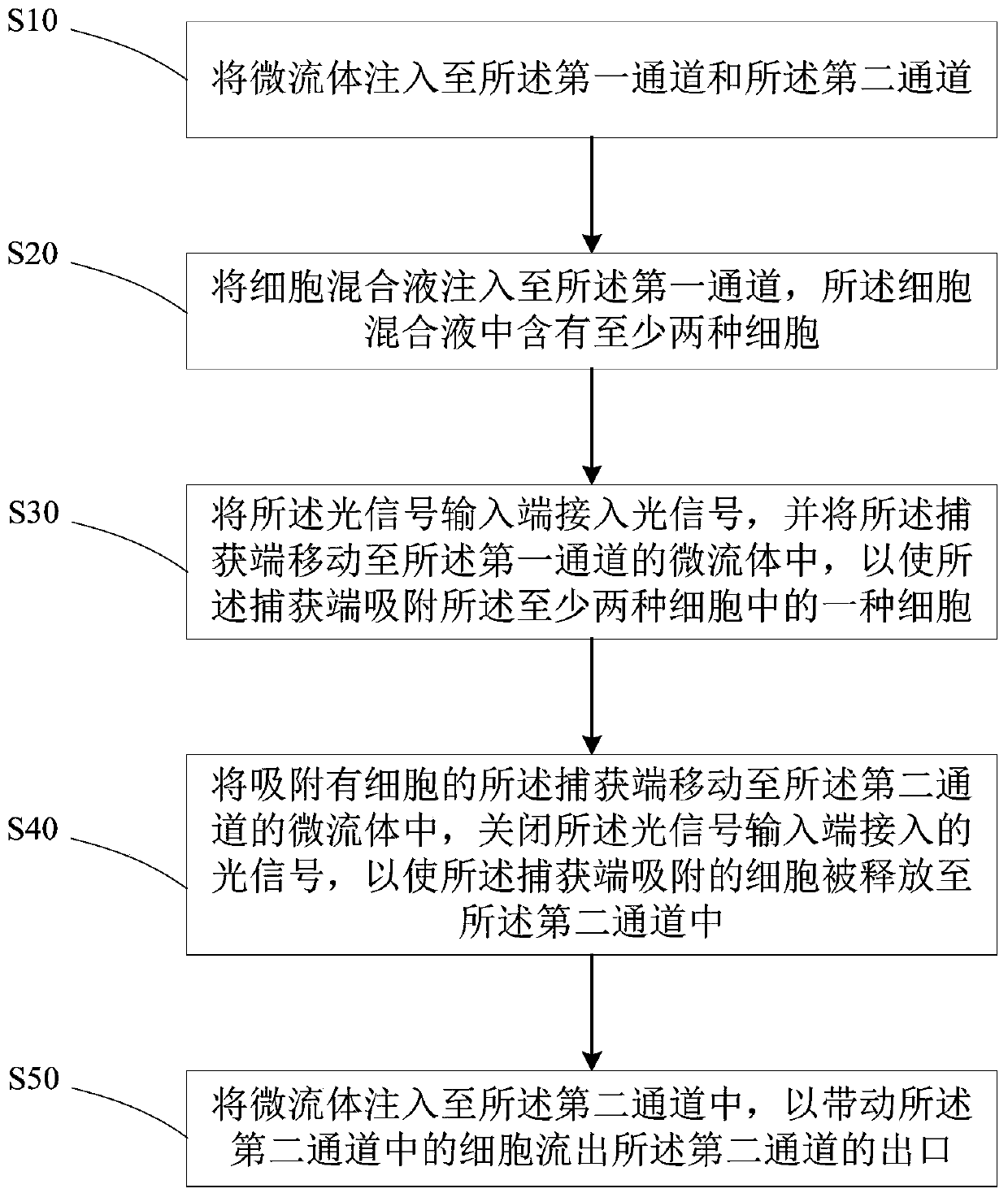

[0055] Such as figure 2 As shown, the method for sorting cells based on an optofluidic cell sorting chip according to Embodiment 2 of the present invention includes the following steps:

[0056] Step S10 : injecting microfluid into the first channel 21 and the second channel 22 .

[0057] Specifically, the microfluid is injected from the first inlet 21a by using a syringe pump, so that the microfluid is filled with the first channel 21 and the second channel 22 . Among them, microfluidics can use fluids that are harmless to biological cells, including deionized water and PBS buffer water.

[0058] Step S20: inject the cell mixture into the first channel 21, the cell mixture contains at least two kinds of cells.

[0059] Specifically, the cell mixture is injected from the first inlet 21 a through a syringe pump, so that the cell mixture is distributed in the first channel 21 .

[0060] Step S30: Connect the optical signal input end 31 to the optical signal, and move the cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com