Large-thickness rack steel plate and production method thereof

A production method and large-thickness technology, applied in the field of metallurgy, can solve the problems of high welding crack sensitivity coefficient, high tempering temperature, welding difficulties, etc., and achieve the effect of improving the original structure, reducing internal stress, and avoiding bursting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

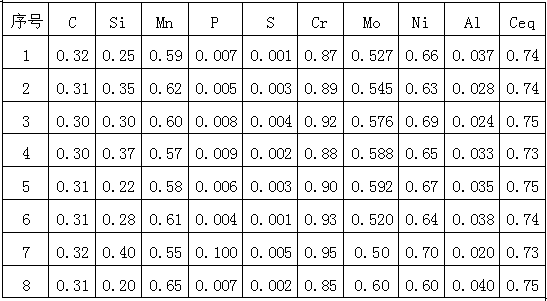

[0018] The thick rack steel plate ZH70Q of this embodiment has a thickness of 180 mm, and its chemical composition and mass percentage are shown in Table 1.

[0019] The production method of the large-thickness rack steel plate ZH70Q in this embodiment includes smelting, heating, rolling, complete annealing, cutting riser and sampling, and heat treatment processes. The specific process steps are as follows:

[0020] (1) Smelting process: LF furnace refining white slag retention time 32min, total refining time 65min, good argon blowing throughout the whole process; before VD vacuum refining, feed Ca-Si wire, control calcium content at 0.0032%, refining vacuum degree 62Pa, vacuum maintenance The time is 25 minutes to ensure that the argon blowing is good throughout the whole process, and the soft blowing state is maintained for the last 5 minutes of VD vacuum refining, and the soft blowing is 10 minutes after the vacuum is broken;

[0021] (2) Heating process: After the steel in...

Embodiment 2

[0028] The thick rack steel plate ZH70Q of this embodiment has a thickness of 170 mm, and its chemical composition and mass percentage are shown in Table 1.

[0029] The production method of the large-thickness rack steel plate ZH70Q in this embodiment includes smelting, heating, rolling, complete annealing, cutting riser and sampling, and heat treatment processes. The specific process steps are as follows:

[0030] (1) Smelting process: LF furnace refining white slag retention time is 35min, total refining time is 68min, argon blowing is good throughout the whole process; Ca-Si line is fed before VD vacuum refining, calcium content is controlled at 0.0037%, refining vacuum is 64Pa, vacuum is maintained The time is 28 minutes, to ensure that the argon blowing is good throughout the whole process, the VD vacuum refining is kept in the soft blowing state for the last 6 minutes, and the soft blowing is 12 minutes after the vacuum is broken;

[0031] (2) Heating process: After the...

Embodiment 3

[0038] The thick rack steel plate ZH70Q of this embodiment has a thickness of 150mm, and its chemical composition and mass percentage are shown in Table 1.

[0039] The production method of the large-thickness rack steel plate ZH70Q in this embodiment includes smelting, heating, rolling, complete annealing, cutting riser and sampling, and heat treatment processes. The specific process steps are as follows:

[0040] (1) Smelting process: LF furnace refining white slag retention time is 33min, total refining time is 62min, argon blowing is good throughout the whole process; Ca-Si line is fed before VD vacuum refining, calcium content is controlled at 0.0034%, refining vacuum is 60Pa, vacuum is maintained The time is 23 minutes, to ensure that the argon blowing is good throughout the whole process, the VD vacuum refining is kept in the soft blowing state for the last 7 minutes, and the soft blowing is 9 minutes after the vacuum is broken;

[0041] (2) Heating process: After the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com