Elastomer thin film, preparation method thereof and flexible pressure sensor comprising elastomer thin film

A pressure sensor and elastomer technology, applied in the field of pressure sensors, can solve the problems of difficult large-scale industrial production, flexible pressure sensors with narrow linear response range, poor repeatability of preparation methods, etc. The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of elastomer film of the present invention, comprises the following steps:

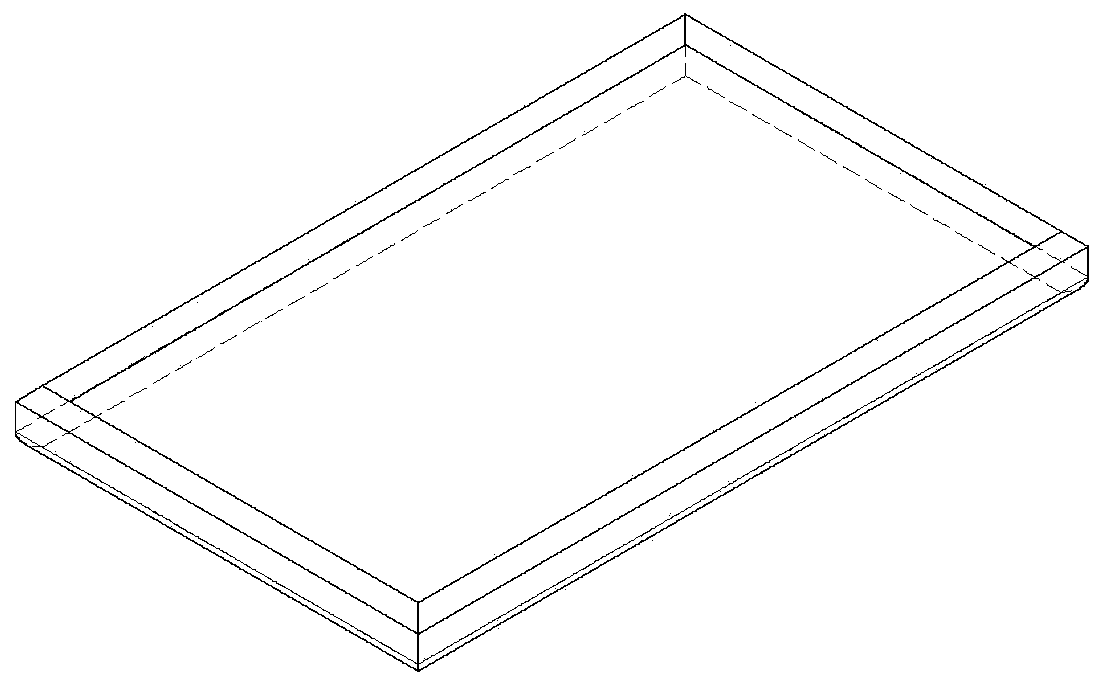

[0037] Step 1. Establish a three-dimensional model of a pouring mold with a groove structure through a three-dimensional modeling software, such as figure 1 shown.

[0038]The shape and size of the outer contour of the casting mold are not particularly limited, and may be cuboid, cube, cylinder, etc. Usually, when the shape of the outer contour of the pouring mold is a cuboid or cube, the length is 50-400 mm, the width is 50-400 mm, and the height is 2-40 mm; when the shape of the outer contour of the casting mold is a cylinder, the diameter is 50-400 mm. 400mm, the height is 2-40mm. It is preferably a cuboid, with a length of 40 mm, a width of 20 mm, and a height of 5 mm.

[0039] The shape of the groove structure provided on the casting mold is also not particularly limited, and may be cuboid, cube, cylinder, etc., which are specifically selected according to the des...

Embodiment 1

[0063] Step 1. Establish a three-dimensional model of a casting mold with a groove structure through a three-dimensional modeling software. The outer contour of the casting mold is a cuboid, with a length of 40mm, a width of 20mm, and a height of 5mm; the groove structure is a cuboid, and the groove The length of the bottom surface of the structure is 36 mm, the width of the bottom surface of the groove structure is 16 mm, the depth of the groove structure is 1 mm, and the wall thickness of the groove structure is 2 mm.

[0064]Step 2: Process the pouring mold of step 1 by using selective laser sintering technology: first preheat the nylon powder to 172°C, and then use a laser beam with a power of 56W and a path spacing of 0.2mm to print layer by layer to form a casting mold. The horizontal dimension of the surface microstructure of the casting mold is 80-200 μm, the height dimension is 50-100 μm, and the surface roughness of the casting mold is 10-40 μm.

[0065] Step 3, pour...

Embodiment 2

[0068] Step 1. Establish a three-dimensional model of a casting mold with a groove structure through a three-dimensional modeling software. The outer contour of the casting mold is cube-shaped, with a length of 50mm, a width of 50mm, and a height of 5mm; the groove structure is cube-shaped, and the groove The length of the bottom surface of the structure is 46 mm, the width of the bottom surface of the groove structure is 46 mm, the depth of the groove structure is 1 mm, and the wall thickness of the groove structure is 2 mm.

[0069] Step 2: Process the pouring mold of step 1 by using selective laser sintering technology: first preheat the nylon powder to 172°C, and then use a laser beam with a power of 48W and a path spacing of 0.25mm to print layer by layer to form a casting mold. The horizontal dimension of the surface microstructure of the casting mold is 60-150 μm, the height dimension is 60-120 μm, and the surface roughness of the casting mold is 10-20 μm.

[0070] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com