Large-load and high-frequency in-situ tension and fatigue tester based on X-ray imaging

A fatigue testing machine and in-situ stretching technology, applied in the direction of applying stable tension/compression to test the strength of materials, using radiation for material analysis, and using applied repetitive force/pulsation force to test the strength of materials, etc., can solve the problem that cannot be exerted Advanced light source detection capabilities, inability to test and characterize high-strength materials, long loading time and other issues, to achieve long life, high load, and fast frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

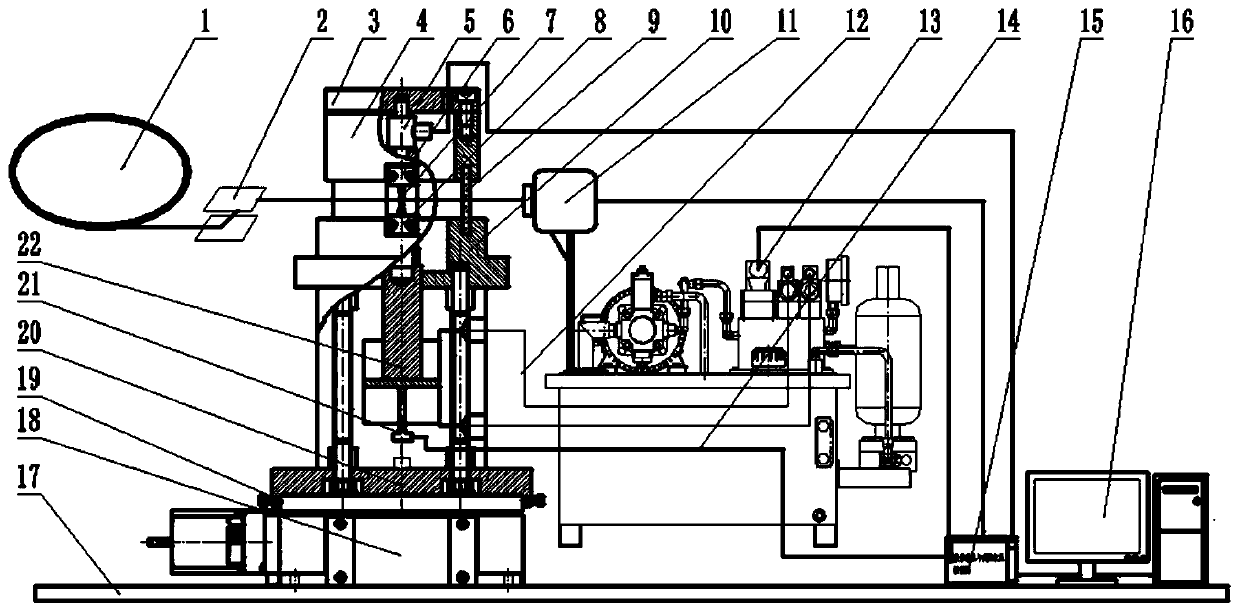

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

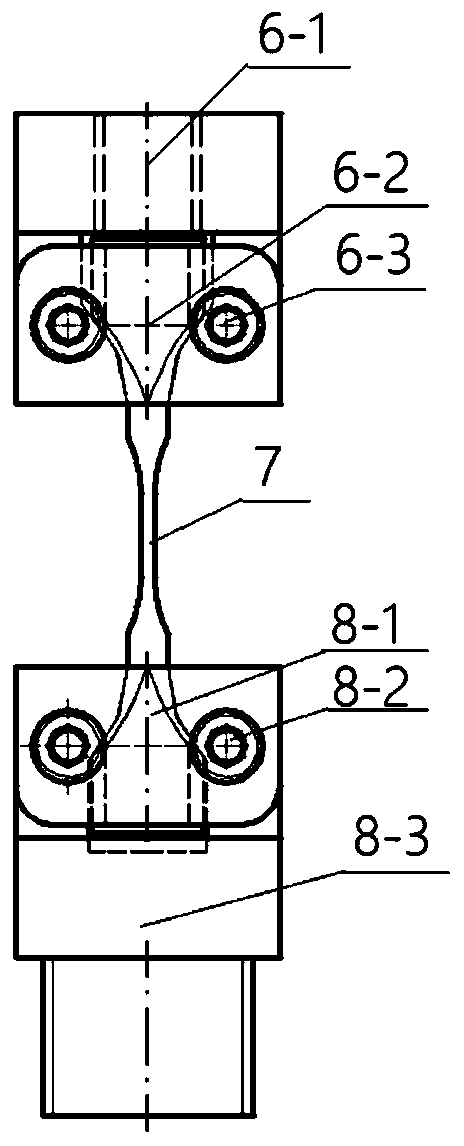

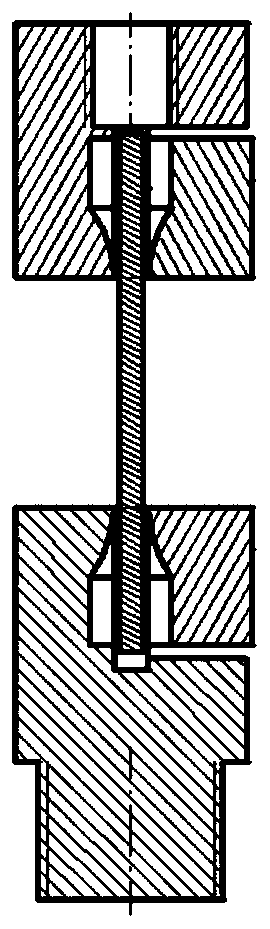

[0035] In the figure, 1 is the synchrotron radiation light source, 2 is the monochromator, 3 is the top cover, 4 is the support cylinder, 5 is the load sensor, 6 is the upper fixture, 7 is the sample, 8 is the lower fixture, and 9 is the transparent enclosure , 10 is a light source experiment platform, 11 is an X-ray detector, 12 is a hydraulic oil pipe, 13 is an electro-hydraulic servo valve, 14 is a hydraulic station, 15 is a data acquisition and controller (that is, a data acquisition and control unit), 16 is a data processing unit, 17 is a light source experiment platform, 18 is an imaging translation stage, 19 is a locking screw, 20 is a testing machine base, 21 is a displacement sensor, and 22 is a servo hydraulic cylinder.

[0036] figure 1 Shown is a large-load high-frequency in-situ tensile and fatigue testing machine based on X-ray imaging, which includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com