True-triaxial coal-rock mass solid-liquid coupling experimental device capable of carrying out instantaneous unloading

A technology of unloading device and experimental device, which is applied in the direction of measuring device, applying stable tension/pressure to test the strength of materials, instruments, etc., can solve the problems that the occurrence and development process of coal rock gas dynamic disaster cannot be reproduced in the whole process, and the lack of instantaneous unloading device, etc. , to achieve the effect of solving the visualization problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

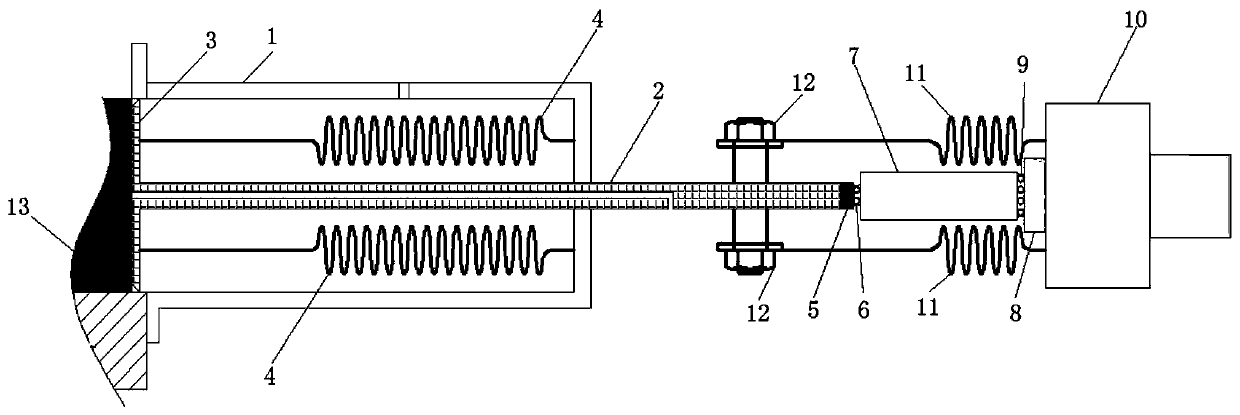

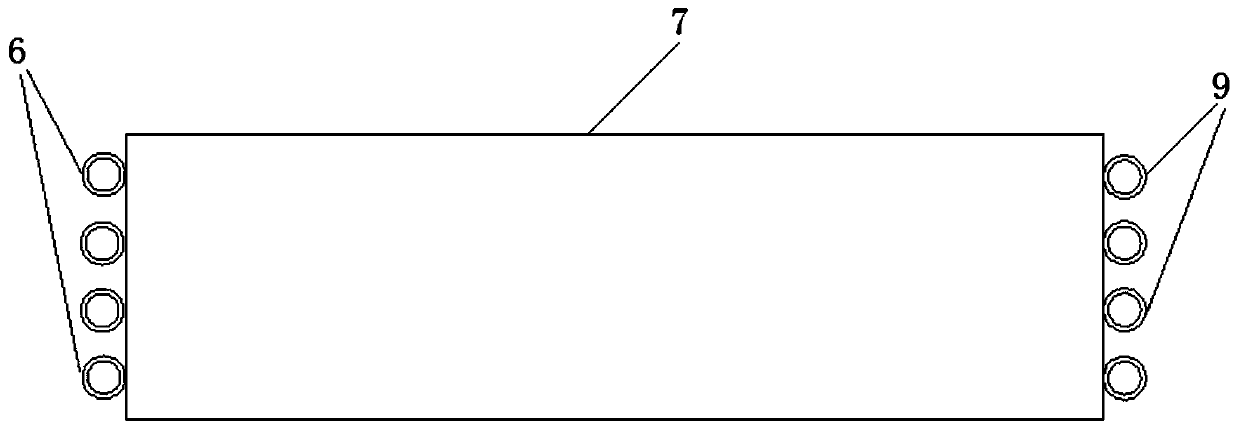

[0041] An instant unloading device for solid-fluid coupling experiment of true triaxial coal-rock mass, refer to figure 1 and image 3 , including: rigid pipeline 1, loading rod 2, loading plate 3, loading plate reset device 4, magnet 5, first pulley 6, pad 7, right pressure head 8, second pulley 9, lateral oil pump 10, loading rod Resetting device 11 and fixed rod 12.

[0042] One end of the rigid pipeline 1 is provided with a through hole for the loading rod 2 to pass through, and the other end of the rigid pipeline 1 is open, and one end of the loading rod 2 passes through the through hole and connects with the inside of the rigid pipeline 1. The loading plate 3 is connected, the loading plate 3 is in contact with the inner wall of the rigid pipe 1 , and the loading plate 3 can slide in the rigid pipe 1 with the movement of the loading rod 2 .

[0043] The loading plate resetting device 4 is located in the rigid pipeline 1, and one end of the loading plate resetting devic...

Embodiment 2

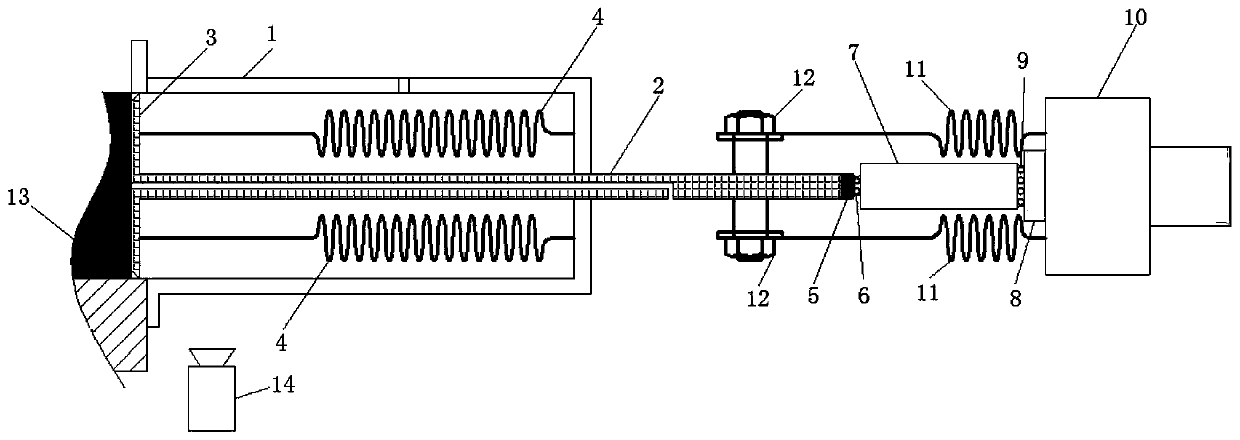

[0047] An instant unloading device for solid-fluid coupling experiment of true triaxial coal-rock mass, refer to figure 2 and image 3 , the rigid pipeline 1 is made of transparent glass fiber reinforced plastic; the rigid pipeline 1 is provided with a high-speed camera 14 outside. After the coal and rock mass is destroyed, the debris flying out consumes energy. During the experiment, a high-speed camera can be used to shoot the experiment process in real time. Observing the movement trajectory of the damaged coal and rock mass is of great help in analyzing the kinetic energy consumed.

Embodiment 3

[0049] An instant unloading device used for the solid-fluid coupling experiment of true triaxial coal-rock mass, the same as that of embodiment 1, the difference is that: the loading plate reset device 4 and the loading rod reset device 11 are both springs, with the lateral oil pump 10 Apply extrusion force to the right pressure head 8, and then push the loading rod 2, push the loading plate 3 to squeeze the coal sample 13, the spring is stretched, and when the extrusion force is removed instantaneously, the spring shrinks instantaneously, so that the loading plate 3 At the same time as the loading rod 2 is pulled back, the loading plate 3 is quickly out of contact with the coal sample, so as to simulate the instability and destruction process of the coal sample when the confining pressure is quickly released; the setting of the magnet 5 helps Adsorb the loading rod 2 on the right pressure head 8 accurately and quickly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com