Color developing system for responding to rot smell of meat through color change, and preparation method and application thereof

A system and reaction technology, which is applied in the direction of chemical reaction analysis of materials, material analysis by observing the influence of chemical indicators, and material analysis by optical means, which can solve the problem of expensive equipment and high requirements for testers. , instrument detection time-consuming and other issues, to avoid harm, reduce toxic effects, reduce the effect of potential toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

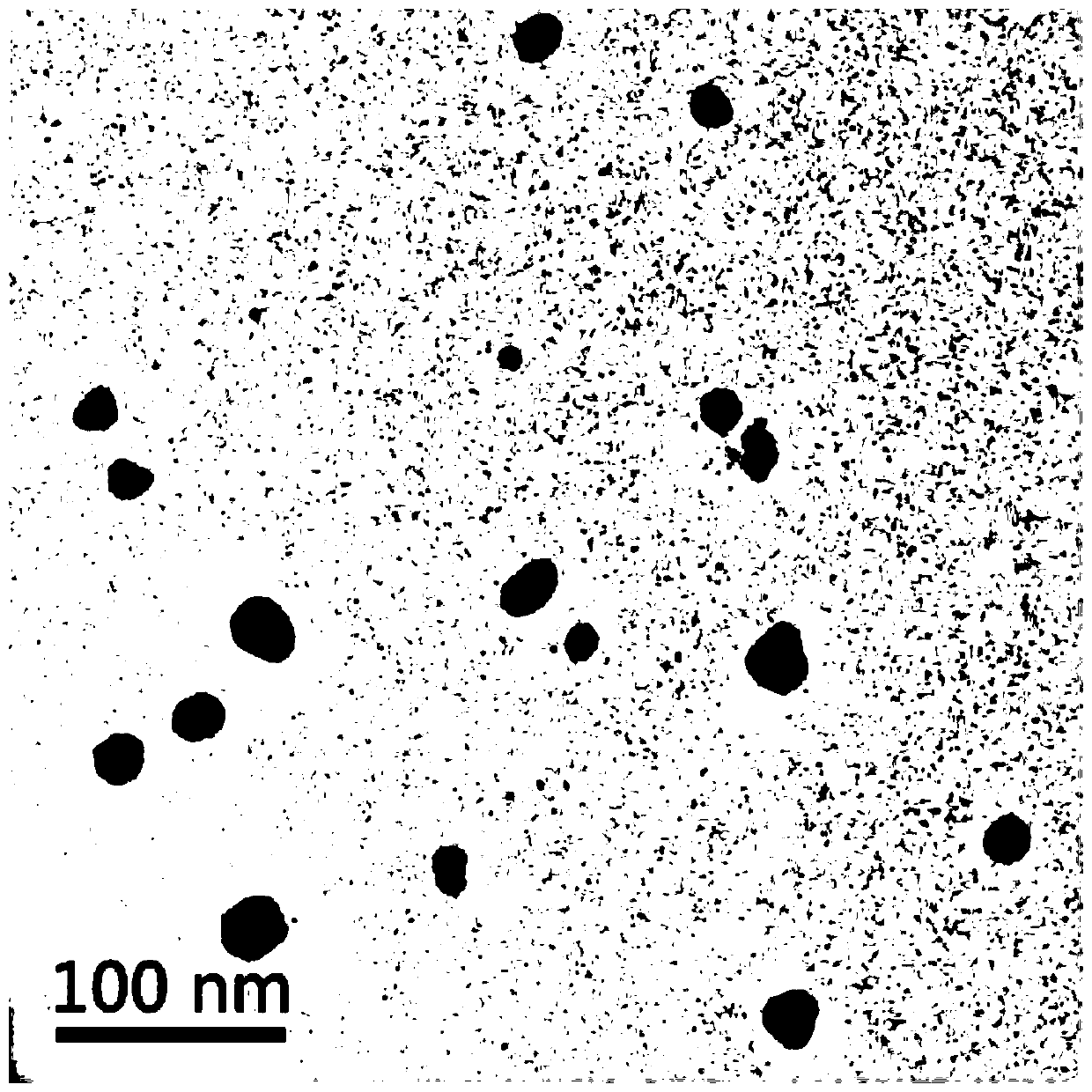

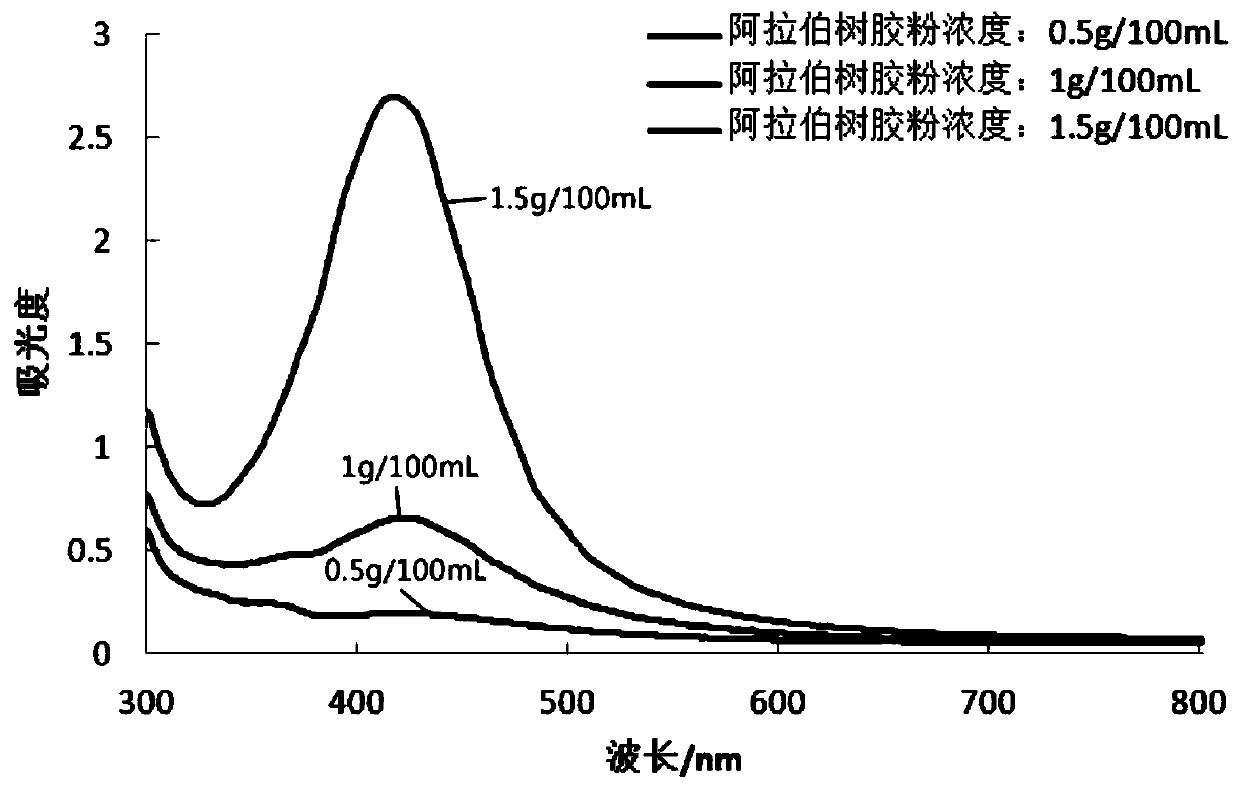

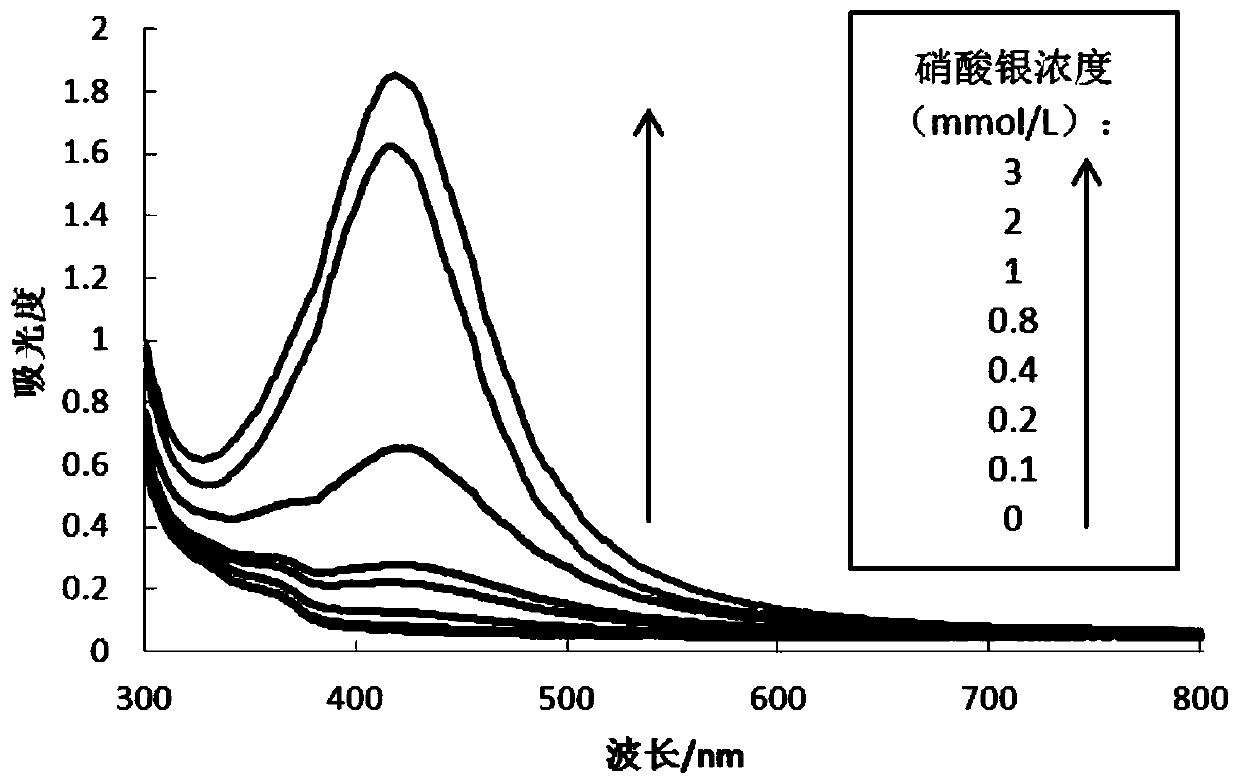

[0045] Example 1: Configure 100mL, 1mmol / L silver nitrate solution, 100mL, 1g / 100mL gum arabic powder solution, stir magnetically until completely dissolved; the volume ratio of silver acid solution and gum arabic solution is 1:1. The mixed system is treated with high temperature and high pressure. The high temperature and high pressure conditions are: 125°C, 232kPa, 15min; the mixed system after high temperature and high pressure treatment is filtered through a 0.45um water filter membrane to obtain the gum arabic powder-nano silver color development system . After the preparation is completed, it is stored in the dark, and the nano-silver chromogenic system is used for ultraviolet-visible (UV-Vis) spectroscopic determination (see Figure 2a), and the shape and structure of the synthesized nano-silver are analyzed by a transmission electron microscope (TEM). The nano-silver color development system was exposed to ammonia, dimethylamine, and trimethylamine gas environments with...

Embodiment 2

[0048] Example 2: Configure 100mL, 1mmol / L silver nitrate solution, 100mL, 0.5g / 100mL gum arabic powder solution, stir magnetically until completely dissolved; the volume ratio of silver acid solution and gum arabic solution is 1:1. The mixed system is treated with high temperature and high pressure. The high temperature and high pressure conditions are: 125°C, 232kPa, 15min; the mixed system after high temperature and high pressure treatment is filtered through a 0.45um water filter membrane to obtain the gum arabic powder-nano silver color development system . After the preparation is completed, it is stored away from light, and the nano-silver chromogenic system is used for ultraviolet-visible (UV-Vis) spectroscopic determination (see Figure 2a).

Embodiment 3

[0049] Example 3: Configure 100mL, 1mmol / L silver nitrate solution, 100mL, 1.5g / 100mL gum arabic powder solution, stir magnetically until completely dissolved; the volume ratio of silver acid solution and gum arabic solution is 1:1. The mixed system is treated with high temperature and high pressure. The high temperature and high pressure conditions are: 125°C, 232kPa, 15min; the mixed system after high temperature and high pressure treatment is filtered through a 0.45um water filter membrane to obtain the gum arabic powder-nano silver color development system . After the preparation is completed, it is stored away from light, and the nano-silver chromogenic system is used for ultraviolet-visible (UV-Vis) spectroscopic determination (see Figure 2a).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com