Array substrate, manufacturing method thereof, and display device

A technology of an array substrate and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, semiconductor/solid-state device components, semiconductor devices, etc., can solve the problems of large depth, uneven surface of signal connection structure, abnormal connection, etc., to ensure display The effect of reducing the defect of falling off and avoiding the abnormal connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

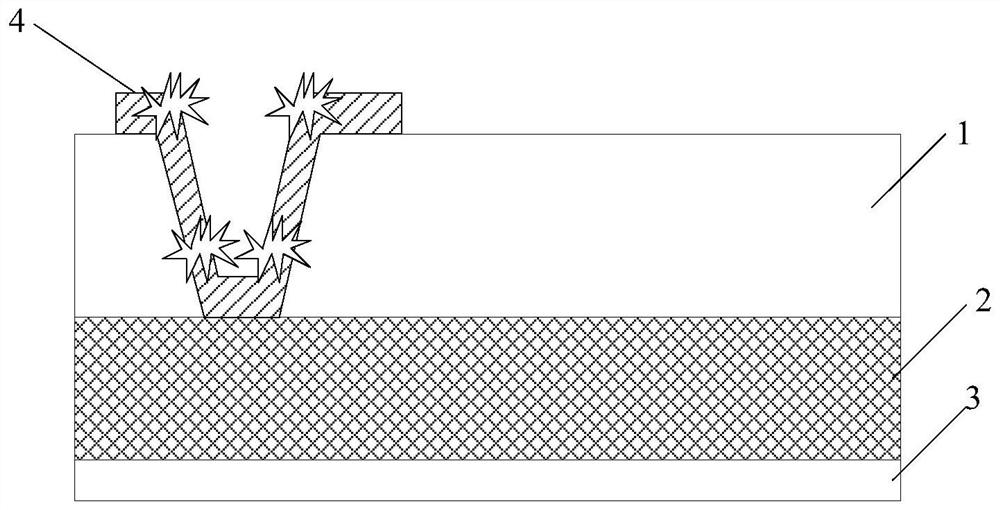

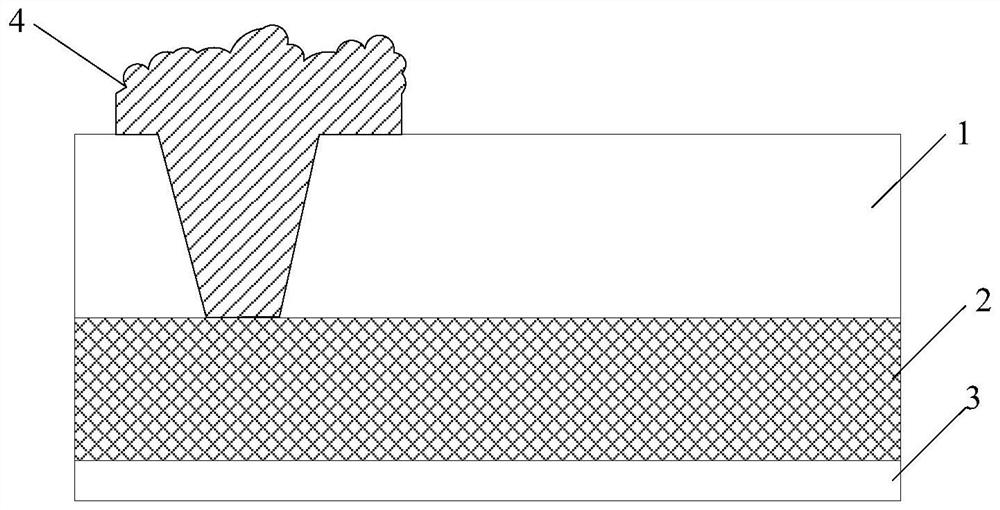

[0119] In this embodiment, the base substrate is a flexible substrate, and the manufacturing method of the array substrate specifically includes the following steps:

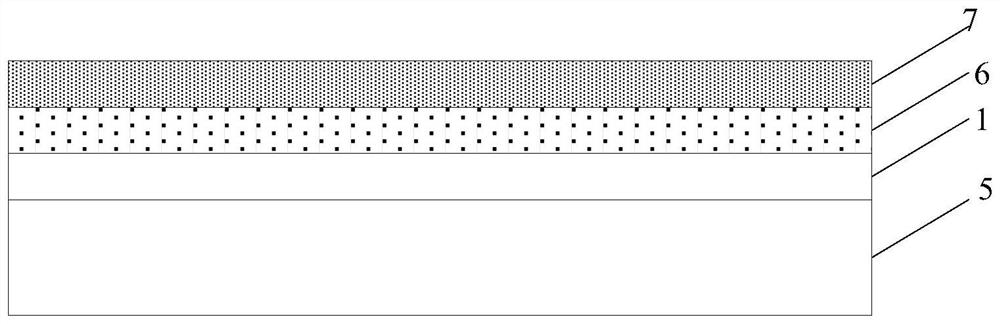

[0120] Step 1, such as image 3 As shown, a rigid carrier 5 is provided, a flexible substrate 1 is formed on the rigid carrier 5, and a first insulating layer 6 and a second insulating layer 7 are sequentially formed on the flexible substrate 1;

[0121] Wherein, the rigid carrier 5 can be a glass substrate or a quartz substrate; specifically, a layer of polyimide can be coated on the rigid carrier to form the flexible substrate 1 .

[0122] The etching rate of the second insulating layer 7 needs to be greater than the etching rate of the first insulating layer 6, and there is no limit to the materials used in the first insulating layer and the second insulating layer, as long as the insulation is satisfied and the etching rate of the second insulating layer 7 is greater than The etching rate of the first insul...

Embodiment 2

[0136] In this embodiment, the base substrate is a flexible substrate, and the manufacturing method of the array substrate specifically includes the following steps:

[0137] Step 1, such as Figure 10 As shown, a rigid carrier 5 is provided, a flexible substrate 1 is formed on the rigid carrier 5, and a negative photosensitive material layer 13 is formed on the flexible substrate 1;

[0138] Wherein, the rigid carrier 5 can be a glass substrate or a quartz substrate; specifically, a layer of polyimide can be coated on the rigid carrier to form the flexible substrate 1 .

[0139] Step 2, such as Figure 11 As shown, an electroplating seed layer 8 and a display unit 2 are formed on the negative photosensitive material layer 13, the electroplating seed layer 8 is connected to the signal input end of the display unit 2, and a protective film 3 covering the display unit 2 is formed;

[0140] Among them, the electroplating seed layer 8 is used for the subsequent electroplating pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com