Inorganic perovskite thick-film composite semiconductor device and preparation method thereof

A composite material, inorganic calcium technology, used in semiconductor devices, electrical components, final product manufacturing, etc., can solve the problem that thin films cannot meet the physical needs of high-energy particle detection, do not have repeatability, and single crystals cannot be grown on a large scale or in large sizes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

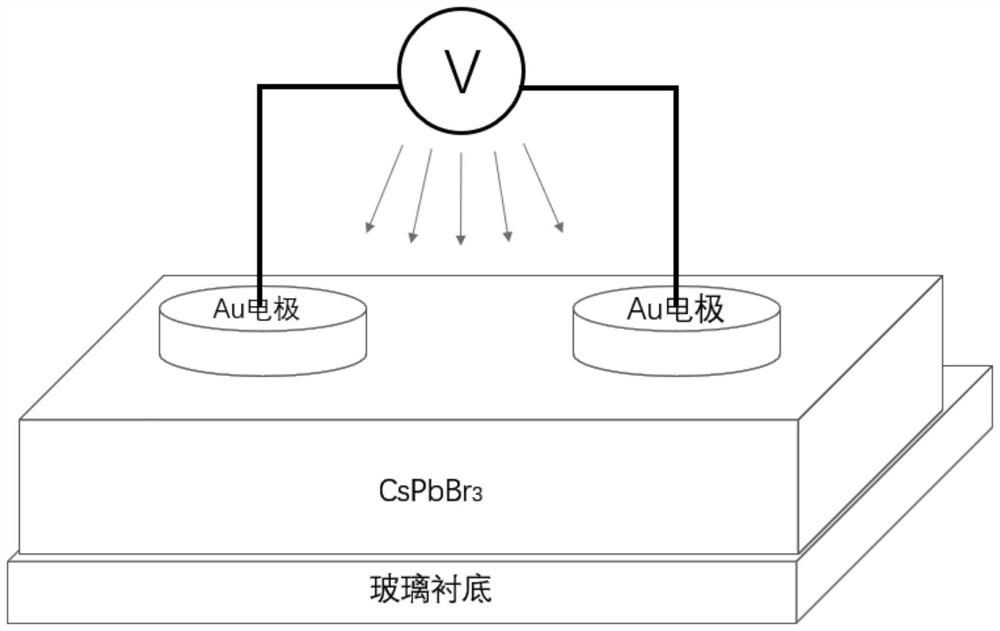

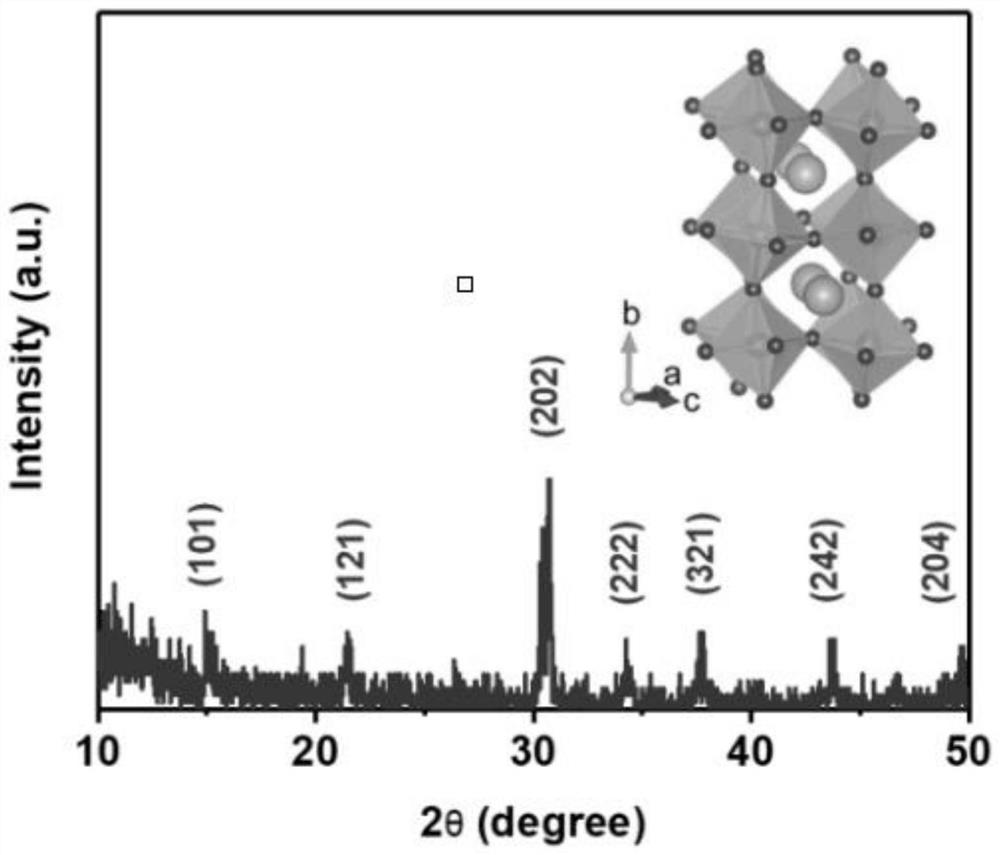

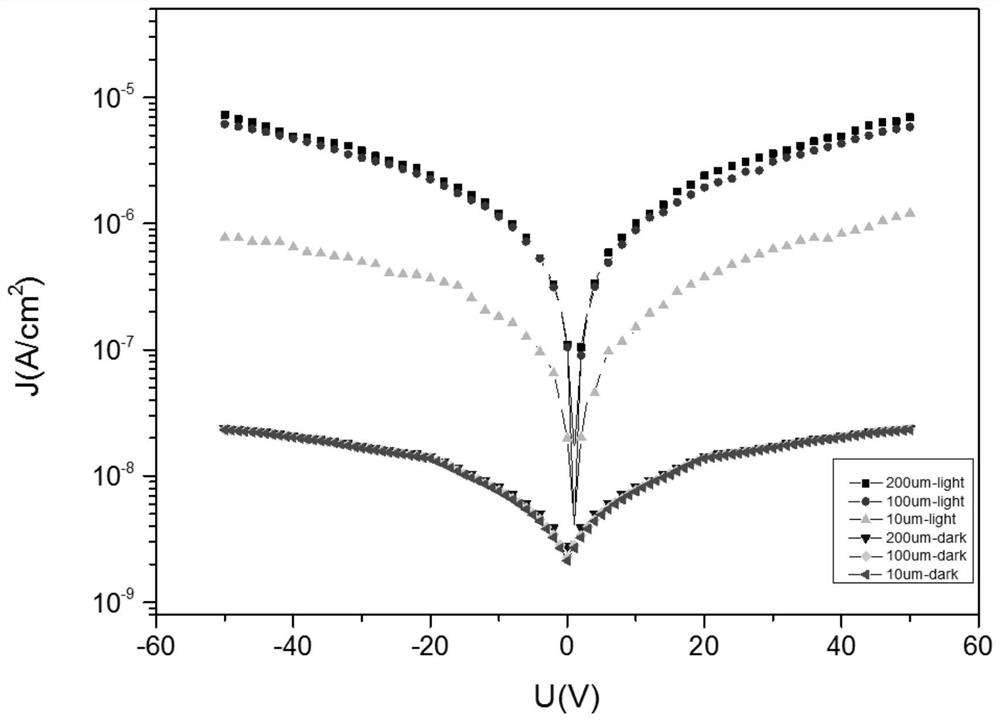

[0035] In this example, see figure 1 , an inorganic perovskite thick-film composite semiconductor device, the transparent glass is used as a substrate with a plane size of 2cm*2cm, and the inorganic perovskite thick-film composite semiconductor device consists of transparent glass, a perovskite light-absorbing layer, a metal The electrode is composed of transparent glass / CsPbBr 3 Composite structure composed of perovskite polycrystalline thick film / Au electrode as an all-inorganic perovskite planar semiconductor detector material, CsPbBr 3 Perovskite polycrystalline thick film as electron hole transport functional layer, CsPbBr 3 The thickness of the perovskite polycrystalline thick film is 10 μm, and the thickness of the Au electrode is 70 nm. The perovskite light-absorbing layer is prepared by a single-step thermal spraying method. The metal electrodes are composed of Au point electrodes. The inorganic perovskite thick-film composite device is used as an X-ray thick-film...

Embodiment 2

[0048] This embodiment is basically the same as Embodiment 1, especially in that:

[0049] In this embodiment, an inorganic perovskite thick-film composite semiconductor device, the transparent glass is used as a substrate with a planar size of 2cm*2cm, and the inorganic perovskite thick-film composite semiconductor device is made of transparent glass, perovskite Composed of mineral light-absorbing layer and metal electrodes, its structure is made of transparent glass / CsPbBr 3 Composite structure composed of perovskite polycrystalline thick film / Au electrode as an all-inorganic perovskite planar semiconductor detector material, CsPbBr 3 Perovskite polycrystalline thick film as electron hole transport functional layer, CsPbBr 3 The thickness of the perovskite polycrystalline thick film is 100 μm, and the thickness of the Au electrode is 80 nm. The perovskite light-absorbing layer is prepared by a single-step thermal spraying method. The metal electrodes are composed of Au po...

Embodiment 3

[0062] This embodiment is basically the same as the previous embodiment, and the special features are:

[0063] In this embodiment, an inorganic perovskite thick-film composite semiconductor device, the transparent glass is used as a substrate with a planar size of 2cm*2cm, and the inorganic perovskite thick-film composite semiconductor device is made of transparent glass, perovskite Composed of mineral light-absorbing layer and metal electrodes, its structure is made of transparent glass / CsPbBr 3Composite structure composed of perovskite polycrystalline thick film / Au electrode as an all-inorganic perovskite planar semiconductor detector material, CsPbBr 3 Perovskite polycrystalline thick film as electron hole transport functional layer, CsPbBr 3 The thickness of the perovskite polycrystalline thick film is 200 μm, and the thickness of the Au electrode is 90 nm. The perovskite light-absorbing layer is prepared by a single-step thermal spraying method. The metal electrodes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com