A lithium battery diaphragm and preparation method thereof

A lithium battery separator and olefin-based film technology, which is applied in secondary batteries, battery pack parts, circuits, etc., can solve the problems of low ionic conductivity and low lithium ion migration number.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Based on the same inventive concept, an embodiment of the present invention also provides a method for preparing a lithium battery separator, the method comprising:

[0037] Add the inorganic oxide precursor to the alumina dispersion, stir for 2-4 hours, add a binder and a second organic additive, and continue stirring for 3-4 hours to obtain a core-shell structure inorganic oxide slurry;

[0038] The inorganic oxide slurry with the core-shell structure is coated on the surface of the porous polyolefin base film, and dried to prepare a lithium battery diaphragm.

[0039] In the present application, in parts by weight, the alumina dispersion is 80-90 parts, the inorganic oxide precursor is 0.4-5 parts, the binder is 3-6 parts, and the organic additive Makes 3-4 servings.

[0040] In the present application, the adhesive is a polyacrylic adhesive, including any one of polymethylacrylate, polyethylacrylate, and polyacrylamide, and the second organic additive includes a we...

Embodiment 1

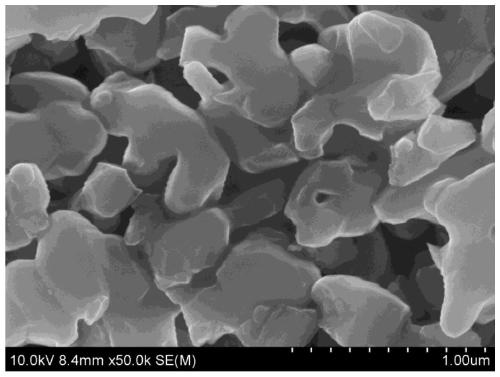

[0044] (1) Calculated by weight, take 45 parts of micron alumina particles, mix 0.398 parts of polyoxyethylene neutral surfactant with 54.602 parts of deionized water, pre-disperse on a mechanical mixer for 10 minutes, and then grind on a grinder for 30 minutes , filtered and iron removed to obtain an alumina dispersion.

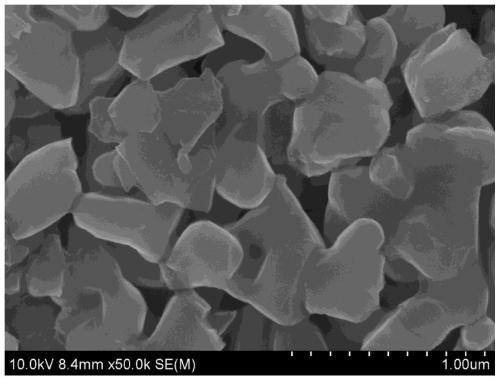

[0045] (2) Take 88.88 parts of alumina dispersion, add 4g ethanol, 0.8g tetraethyl orthosilicate, stir for 2-4 hours, add 6 parts of polyacrylic acid, 3.7 parts of polyoxyethylene neutral surfactant, stir for 3- After 4 hours, a coating slurry of a core-shell structure oxide was obtained.

[0046] (3) Apply the coating slurry to the surface of a 12-micron PE diaphragm by scraping, and dry it at 60 degrees Celsius for 1 hour to obtain a single-sided coated SiO 2 @Al 2 o 3 / PE separator, the thickness of the inorganic layer is 4 microns.

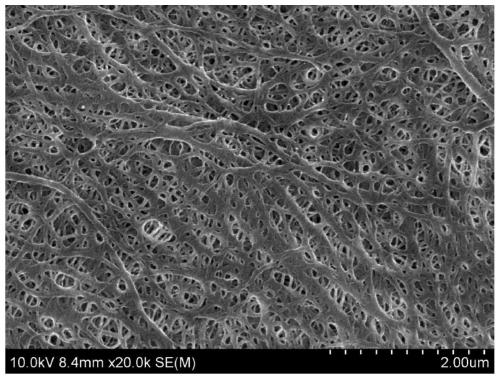

[0047]Coat one side with SiO 2 @Al 2 o 3 / PE diaphragm for morphology characterization, air permeability, electrica...

Embodiment 2

[0049] (1) Calculated by weight, take 45 parts of micron alumina particles, mix 0.398 parts of polyoxyethylene neutral surfactant with 54.602 parts of deionized water, pre-disperse on a mechanical mixer for 10 minutes, and then grind on a grinder for 30 minutes , filtered and iron removed to obtain an alumina dispersion.

[0050] (2) Take 88.88 parts of alumina dispersion, add 4g ethanol, 1.4g tetraethyl orthosilicate, stir for 2-4 hours, add 6 parts of polyacrylic acid, 3.7 parts of polyoxyethylene neutral surfactant, stir for 3- After 4 hours, a coating slurry of a core-shell structure oxide was obtained.

[0051] (3) Coat the coating slurry on the surface of a 12-micron PE diaphragm by scrape coating, and dry it at 60 degrees Celsius for 1 hour to obtain a single-sided coated SiO 2 @Al 2 o 3 / PE separator, the thickness of the inorganic layer is 4 microns.

[0052] Coat one side with SiO 2 @Al 2 o 3 / PE diaphragm for morphology characterization, air permeability, ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com