Preparation method and application of organic and inorganic hybrid thin film

An inorganic and organic technology, applied in the field of preparation and application of organic-inorganic hybrid films, to achieve the effects of improving stability, easy mass production, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing an organic-inorganic hybrid film, the specific preparation steps are as follows:

[0032] Step 1: Mix 10mL of 2mg / mL ethanol solution of graphene oxide with 5mL of 30wt.% ethanol solution of ferric 4-ethylbenzenesulfonate with a mass fraction of 30wt.% and ultrasonically mix for 1h, and the dispersion power is 600w to obtain a mixed solution ;

[0033] Step 2: Heat the mixed solution obtained in Step 1 to 80°C in a polytetrafluoroethylene bottle and dry it for 1 hour to form a film;

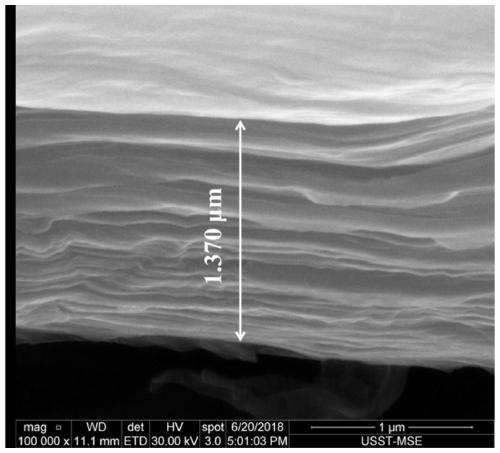

[0034] Step 3: Place the film obtained in step 2 in pyrrole steam for 30 minutes to polymerize the pyrrole monomer, then wash it twice in ethanol solution and once in dimethyl carbonate solution to obtain an organic film with a thickness of about 10 μm. Sulfonated polypyrrole covalently modified inorganic graphene oxide membrane, that is, organic-inorganic hybrid thin film.

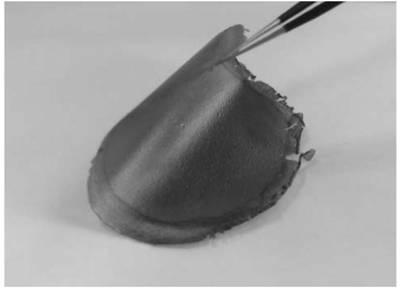

[0035] from figure 1 It can be seen that the synthesized organic-inorganic hybrid film pr...

Embodiment 2

[0039] A method for preparing an organic-inorganic hybrid film, the specific preparation steps are as follows:

[0040]Step 1: 5 mL of 5 mg / mL ethanol solution of graphene oxide and 5 mL of 50% ethanol solution of ferric 4-ethylbenzenesulfonate with a mass fraction of 50% were ultrasonically mixed for 1 hour, and the dispersion power was 600w to obtain a mixed solution;

[0041] Step 2: Using a glass fiber diaphragm as a filter membrane, the mixed solution in step 1 is filtered by a water pump for 10 hours under reduced pressure to form a thin film;

[0042] Step 3: Place the membrane obtained in step 2 in pyrrole steam for 1.5 hours to polymerize the pyrrole monomer, and then wash it in acetonitrile solution for 3 times to obtain inorganic graphite oxide covalently modified with organic sulfonated polypyrrole with a thickness of about 20 μm Alkene films, that is, organic-inorganic hybrid films.

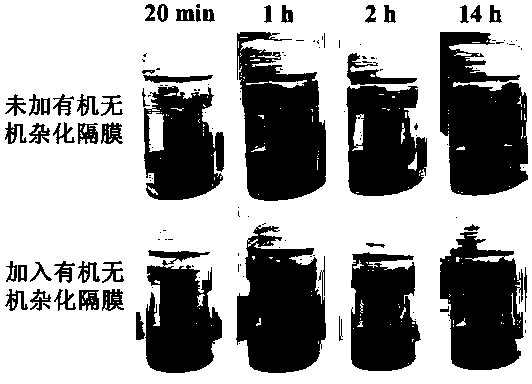

[0043] Such as Figure 4 As shown, the organic-inorganic hybrid film was place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com