Multi-contact layer swinging friction nanometer power generator fabricated according to 3D printing technology and for degradation of organic pollutant

A technology of organic pollutants and nanogenerators, applied in the fields of triboelectric generators, water pollutants, water/sludge/sewage treatment, etc. The effect of current output, improving charge density, and improving data output stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] In the present invention, unless stated to the contrary, the used orientation words such as "upper and lower" indicate the direction in the figure; "filling degree" is defined as the area formed during the contact and separation process.

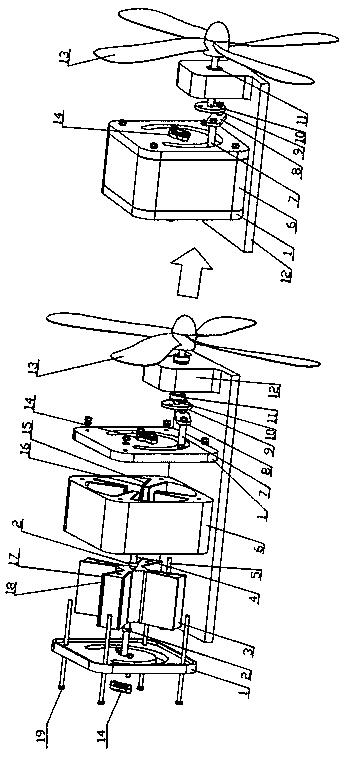

[0030] Such as figure 1As shown, a swing friction nanogenerator based on 3D printing technology for the degradation of organic pollutants includes a friction power generation mechanism, a crank rocker mechanism and a fan blade mechanism. In the friction power generation mechanism, the arrayed fixed base 6 is passed through the bolt The screw connector 19 is fixed between the end covers 1 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com