Ternary blend organic solar cells based on one donor polymer and two acceptors

A solar cell and polymer technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult to control the shape, limit the development of ternary OSC, and difficult to control the shape of ternary mixture OSC.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0226] Example 1: Selection and Synthesis of Materials

[0227] Preparation of Donor and Acceptor Materials. These materials are selected from:

[0228]

[0229]

[0230]

Embodiment 2

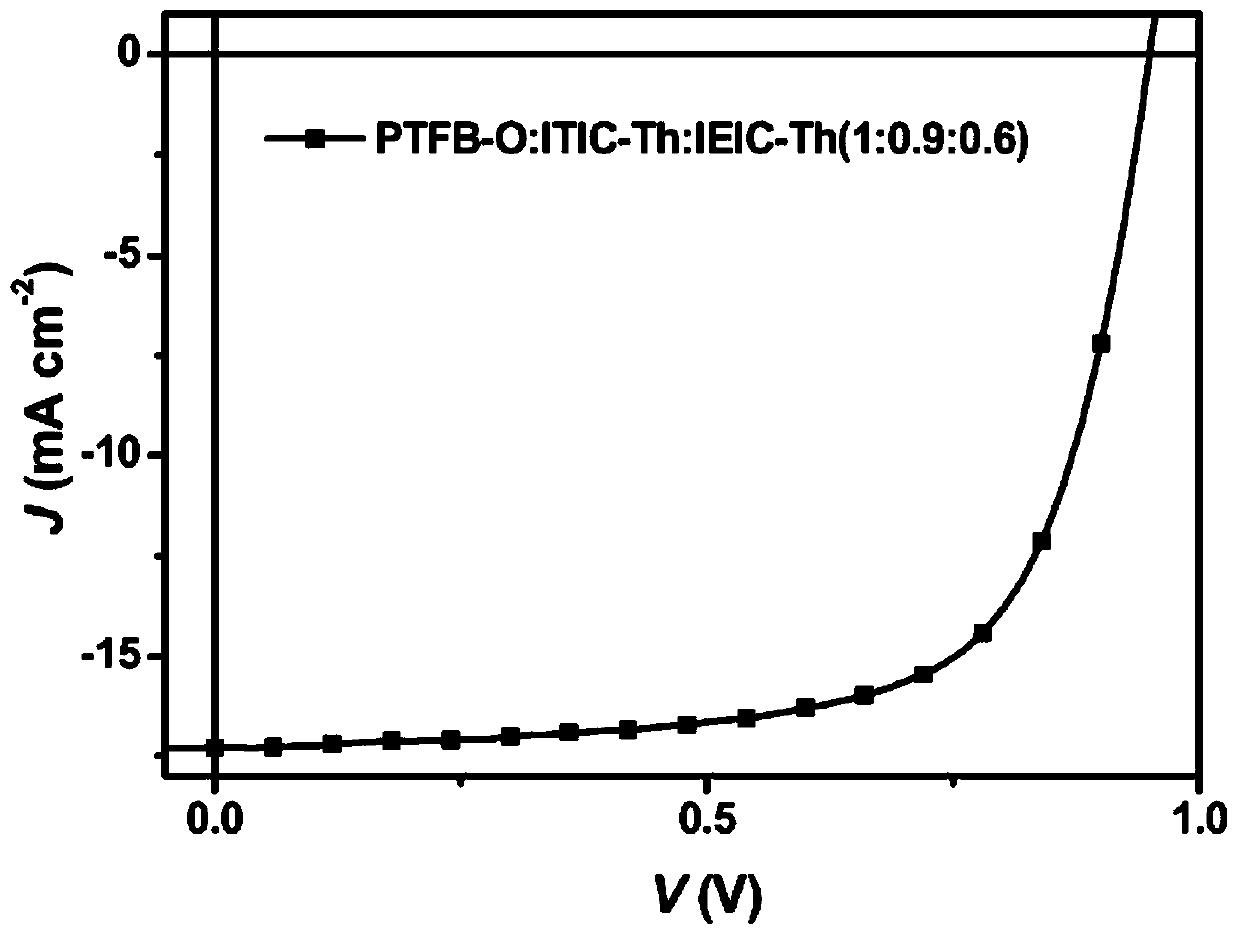

[0231] Example 2: Solar cells are fabricated and tested

[0232] A pre-patterned ITO coated glass with a sheet resistance of -15Ω / square was used as the substrate. Cleaning was performed in each step by continuous sonication for 15 minutes in soapy deionized water, deionized water, acetone, and isopropanol. with UV-O 3 Cleaner (Novascan, PSD series digital UV ozone system) further treated the washed substrates for 30 minutes. A topcoat of ZnO (diethylzinc solution, 15 wt% in toluene, diluted with tetrahydrofuran) was spin-coated on ITO substrates with a spin speed of 5000 rpm for 30 s, and then baked at 150 °C for 20 min in air . An active layer solution was prepared in CB (polymer:SMA weight ratio 1:1.5). The polymer concentration of PTFB-O is 6 mg mL -1 . To completely dissolve the polymer, the active layer solution was stirred on a hot plate at 100°C for at least 1 hour.

[0233] The polymer solution and ITO substrate were preheated on a hot plate at 100 °C before sp...

Embodiment 3

[0236] Example 3: AFM analysis

[0237] AFM measurements were performed by using a scanning probe microscope-Dimension 3100 in tapping mode. All film samples were spin-coated on ITO / ZnO substrates. Figure 6A -F shows an AFM image.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com