Environment-friendly nontoxic water-based nail polish remover and preparation method thereof

A nail remover, water-based technology, used in manicures, pedicures, pharmaceutical formulations, etc., can solve problems such as nail dehydration, insufficient solubility of nail polish, and susceptibility to breast cancer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

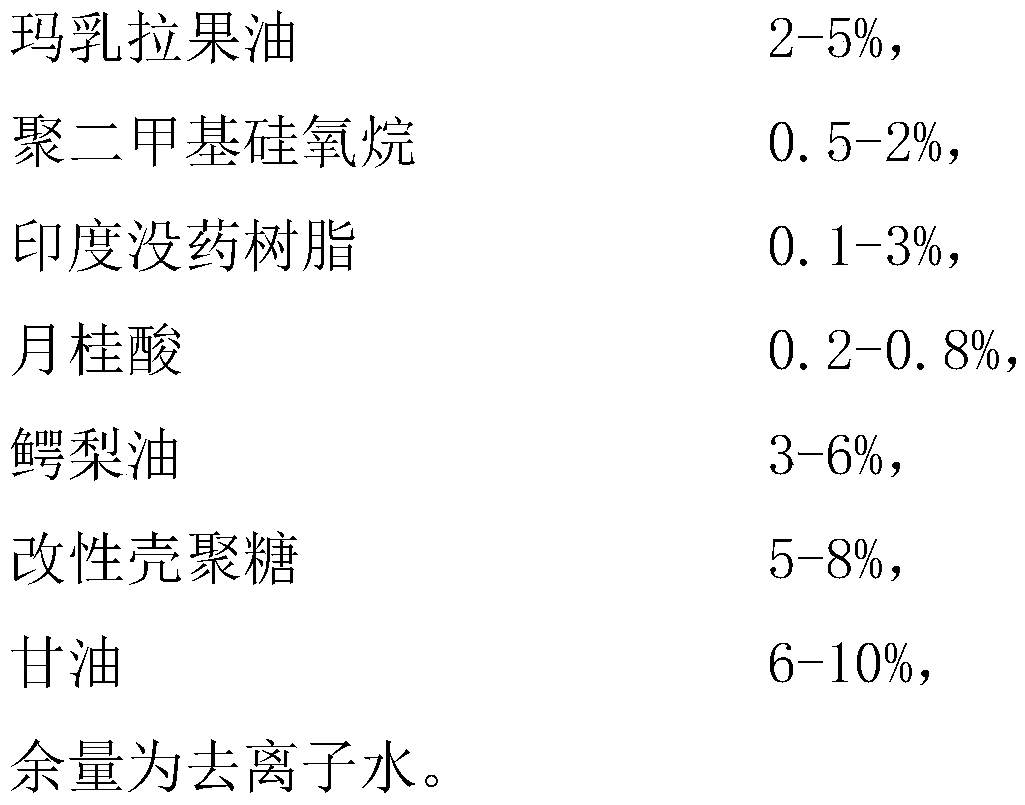

[0032] 1. Raw material ratio (weight fraction)

[0033]

[0034] 2. Preparation method

[0035] (1) according to above-mentioned proportioning, weigh each raw material for subsequent use;

[0036] (2) According to the above proportions, Mala fruit oil, Indian myrrh resin, lauric acid, avocado oil, and glycerin were added to the ultrasonic instrument in turn for pretreatment. The ultrasonic power was 300 Hz, and the ultrasonic time was 10 minutes to obtain a mixture. 1, mixture I was incubated in a water bath at 60° C. for 15 minutes;

[0037] (3) Add polydimethylsiloxane to mixture I, and continue ultrasonic treatment to obtain mixture II, the ultrasonic power is 500 Hz, and the ultrasonic time is 10 min;

[0038] (4) Add modified chitosan and deionized water to the mixture II, and perform ultrasonic treatment with an ultrasonic power of 200 Hz and an ultrasonic time of 10 min to obtain the environmentally friendly and non-toxic aqueous nail remover.

Embodiment 2

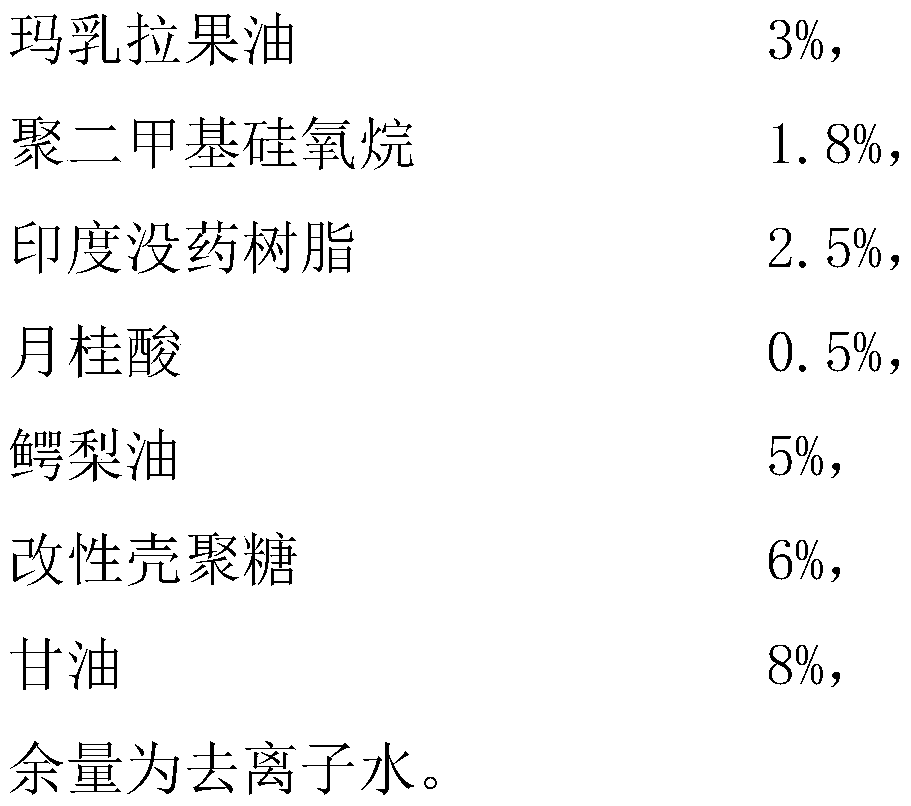

[0040] 1. Raw material ratio (weight fraction)

[0041]

[0042]

[0043] 2. Preparation method

[0044] (1) according to above-mentioned proportioning, weigh each raw material for subsequent use;

[0045] (2) According to the above proportions, add marula fruit oil, Indian myrrh resin, lauric acid, avocado oil, and glycerin into the ultrasonic instrument in turn for pretreatment. The ultrasonic power is 400 Hz, and the ultrasonic time is 10 minutes to obtain a mixture 1, mixture I was incubated in a water bath at 70° C. for 10 min;

[0046] (3) Add polydimethylsiloxane to mixture I, and continue ultrasonic treatment to obtain mixture II, the ultrasonic power is 600 Hz, and the ultrasonic time is 10 min;

[0047] (4) Carboxymethyl chitosan and deionized water were added to the mixture II, and ultrasonic treatment was performed with the ultrasonic power at 300 Hz and the ultrasonic time at 10 min to obtain the environmentally friendly and non-toxic aqueous nail remover....

Embodiment 3

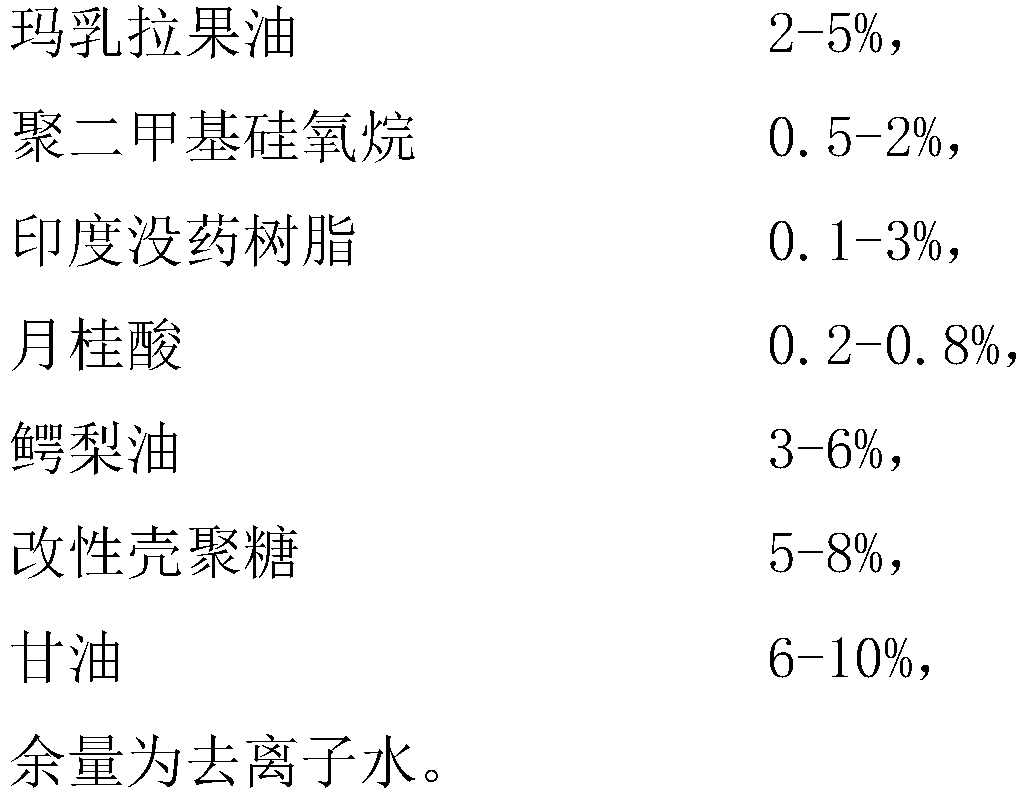

[0049] 1. Raw material ratio (weight fraction)

[0050]

[0051] 2. Preparation method

[0052] (1) according to above-mentioned proportioning, weigh each raw material for subsequent use;

[0053](2) According to the above proportions, Mala fruit oil, Indian myrrh resin, lauric acid, avocado oil, and glycerin were added to the ultrasonic instrument in turn for pretreatment. The ultrasonic power was 500 Hz, and the ultrasonic time was 5 minutes to obtain a mixture. 1, mixture I was incubated in a water bath at 80°C for 15min;

[0054] (3) Add polydimethylsiloxane to mixture I, and continue ultrasonic treatment to obtain mixture II. The ultrasonic power is 700 Hz, and the ultrasonic time is 15 min;

[0055] (4) Carboxymethyl chitosan and deionized water were added to the mixture II, and ultrasonic treatment was performed with the ultrasonic power at 500 Hz and the ultrasonic time at 5 min, to obtain the environmentally friendly and non-toxic aqueous nail remover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com