Oil field high-difficulty waste water treatment process

A wastewater treatment and process technology, which is applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of turbid water quality, high investment cost, high operation cost, etc., and achieve control Investment cost and operating cost, good practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

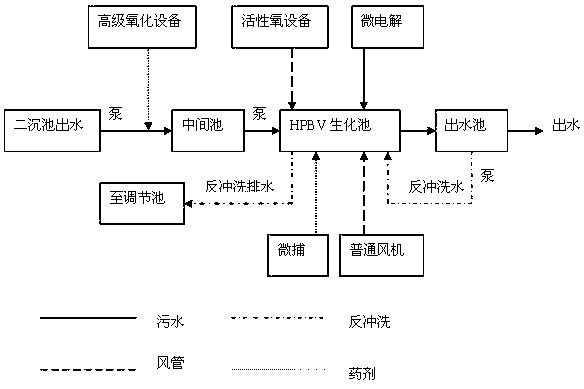

[0007] A process for treating difficult wastewater in an oil field. The process includes a secondary settling tank, an intermediate tank, a biochemical tank, an outlet pool, and a regulating tank. The sewage first enters the secondary settling tank for sedimentation, and the effluent from the secondary settling tank flows into the intermediate tank. The sewage is oxidized by the oxidation equipment, and the sewage is transported to the biochemical pool through the pump body after sedimentation in the intermediate pool. The sewage in the biochemical pool is micro-captured by the active oxygen equipment and the micro-electrolysis equipment, and the fan is set at the same time to speed up the reaction. The speed of the reaction in the biochemical pool is discharged into the regulating pool through backwashing, the sewage treated in the biochemical pool is discharged into the effluent pool, and the clear water discharged from the effluent pool is discharged from the system. The wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com