Chitin/graphene composite sponge, and preparation method and application thereof

A graphene composite and chitin technology, applied in applications, medical formulations, surgical adhesives, etc., can solve the problems of unfriendly environment, toxic reagents, and difficulty in large-scale production, so as to reduce the risk of secondary bleeding and excellent hemostasis Effect, preparation method Green effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The mixed powder of chitin and flake graphite with a mass ratio of 200:1 was dried in a vacuum oven at 105 °C for 4 h. Then the composite material was obtained by ball milling for 8 h in batch operation (10 min pause every 20 min, rotation speed 180 r / min).

[0030] The obtained composite material was added to 10% NaOH / 4% urea solvent at a mass ratio of 2:100, frozen at -40°C, then thawed while stirring at 23°C, freezing and thawing twice to make it evenly dispersed , after low-speed centrifugation (1800 rpm, time 20 min) to remove unexfoliated graphite flakes. Add 1 mL of cross-linking agent epichlorohydrin dropwise to every 10 g of the solution, and stir at 0 °C for 0.2 h to obtain a homogeneous solution. Continue to stand at 2 °C for 12 h to obtain chitin / graphene hydrogel.

[0031] The above hydrogel was dialyzed at 50 °C for 10 days, and then freeze-dried at -40 °C for 48 h to obtain a chitin / graphene composite sponge.

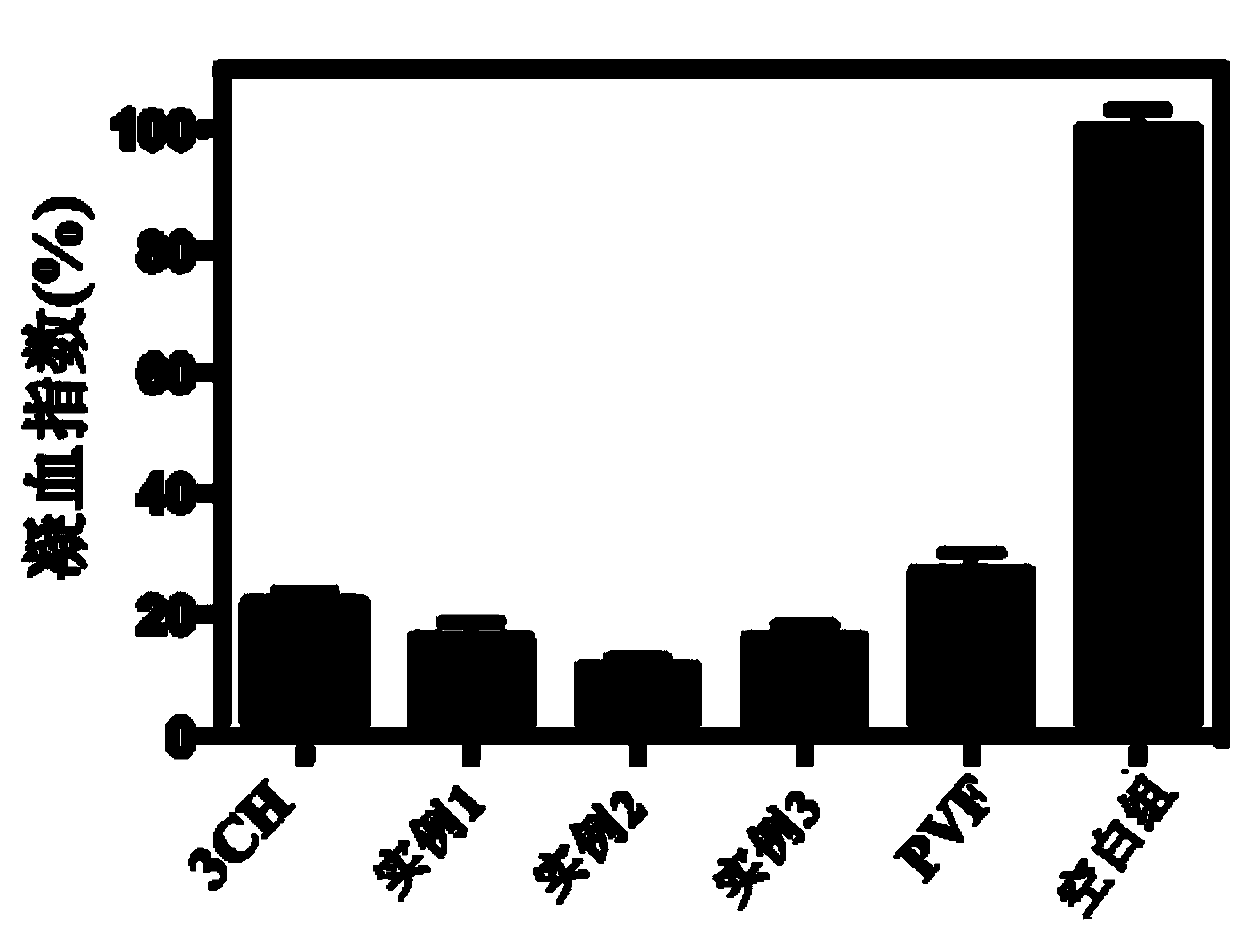

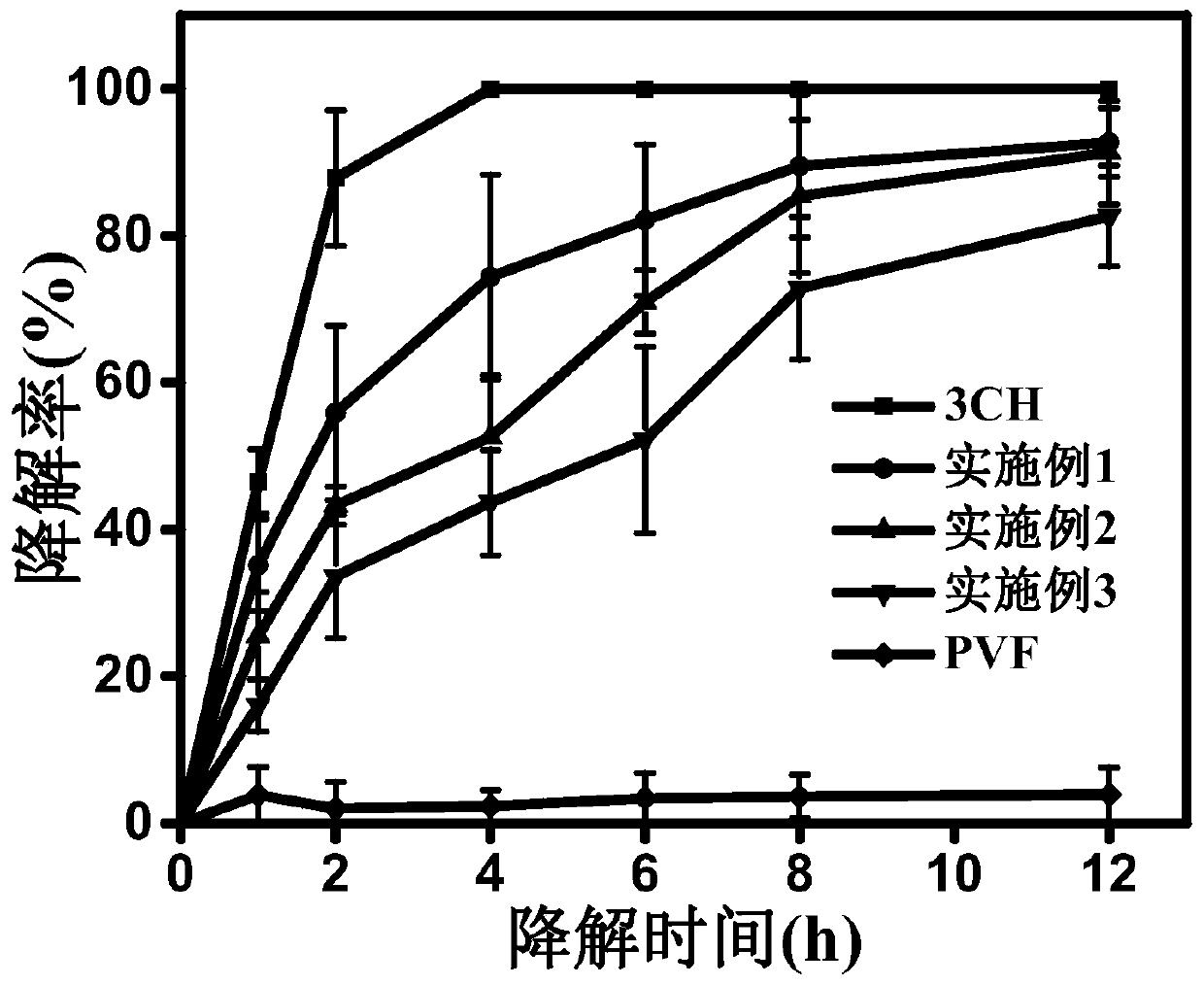

[0032] The coagulation index of the prepa...

Embodiment 2

[0034] The mixed powder of chitin and flake graphite with a mass ratio of 100:1 was dried in a vacuum oven at 100 °C for 6 h. Then, the composite material was obtained by ball milling for 4 h in batch operation (12 min pause every 25 min, speed 200 r / min).

[0035] The obtained composite material was added to 8% NaOH / 2% urea solvent at a mass ratio of 1:100, frozen at -30°C, then melted while stirring at 30°C, freeze-thawed 4 times to make it evenly dispersed , after low-speed centrifugation (2000 rpm, time 18 min) to remove unexfoliated graphite flakes. Add 0.5 mL of cross-linking agent epichlorohydrin dropwise to every 10 g of the solution, and stir at 4 °C for 1.2 h to obtain a homogeneous solution. Continue to stand at 4 °C for 8 h to obtain chitin / graphene hydrogel.

[0036] The above hydrogel was dialyzed at 40 °C for 14 days, and then freeze-dried at -80 °C for 52 h to obtain a chitin / graphene composite sponge.

[0037] The coagulation index of the prepared composite...

Embodiment 3

[0039] The mixed powder of chitin and flake graphite with a mass ratio of 20:1 was dried in a vacuum oven at 80 °C for 8 h. Then, the composite material was obtained by ball milling for 5 h in batch operation (stop for 15 min every 30 min, with a rotation speed of 210 r / min).

[0040] The obtained composite material was added to 15% NaOH / 8% urea solvent at a mass ratio of 6:100, frozen at -20 °C, then melted and stirred at 20 °C, and frozen and thawed 6 times to make it evenly dispersed , after low-speed centrifugation (3000 rpm, time 5 min) to remove unexfoliated graphite flakes. 2 mL of cross-linking agent epichlorohydrin was added dropwise to every 10 g of the solution, and stirred at 0 °C for 2 h to obtain a homogeneous solution. Continue to stand at 0°C for 24 h to obtain chitin / graphene hydrogel.

[0041] The above hydrogel was dialyzed at 60 °C for 7 days, and then freeze-dried at -50 °C for 72 h to obtain a chitin / graphene composite sponge.

[0042] The coagulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com