Fabricated corrugated steel plate shear wall structure and construction method thereof

A steel plate shear wall and corrugated technology, applied in the direction of walls, building components, building types, etc., can solve the problems of easy cracking, brittleness of the wall, increased reinforcement and maintenance costs, and affecting normal use status, etc., to achieve light weight , Simple structure, good deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

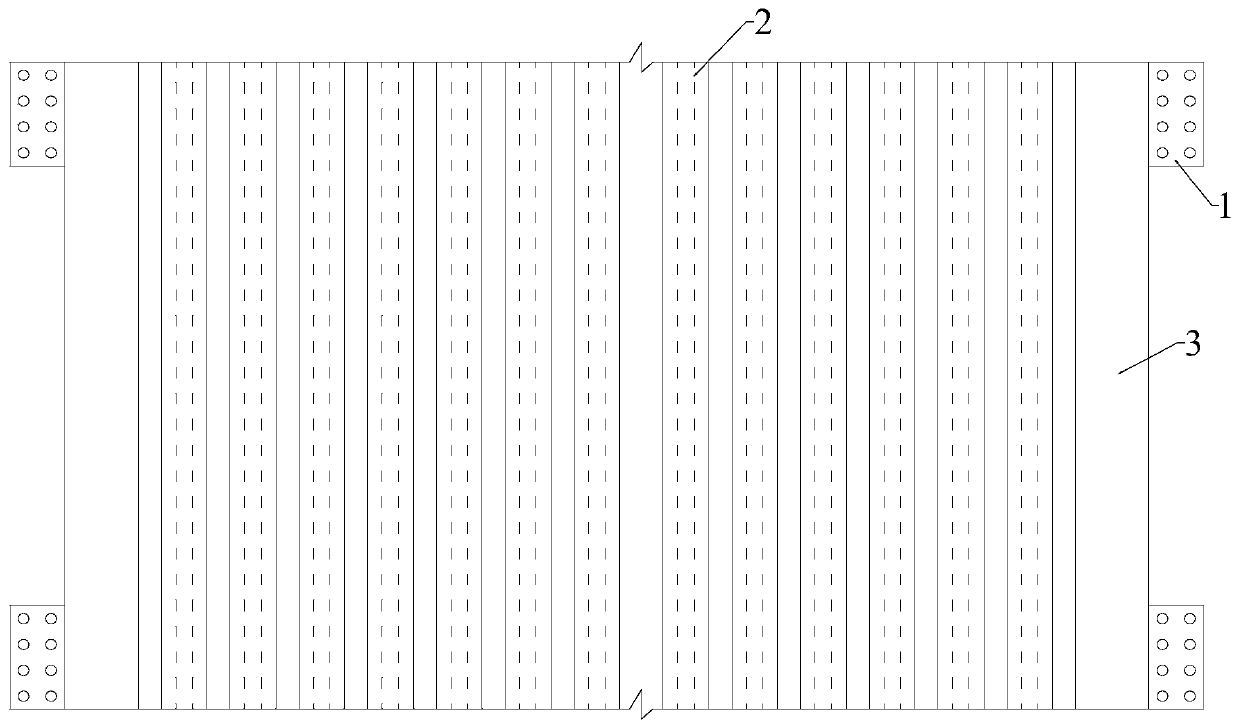

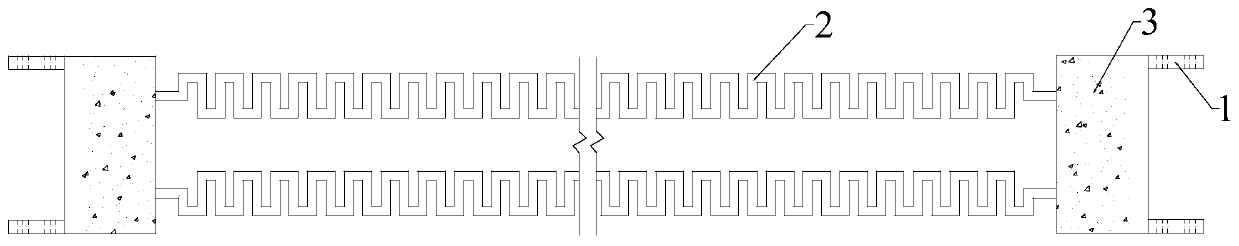

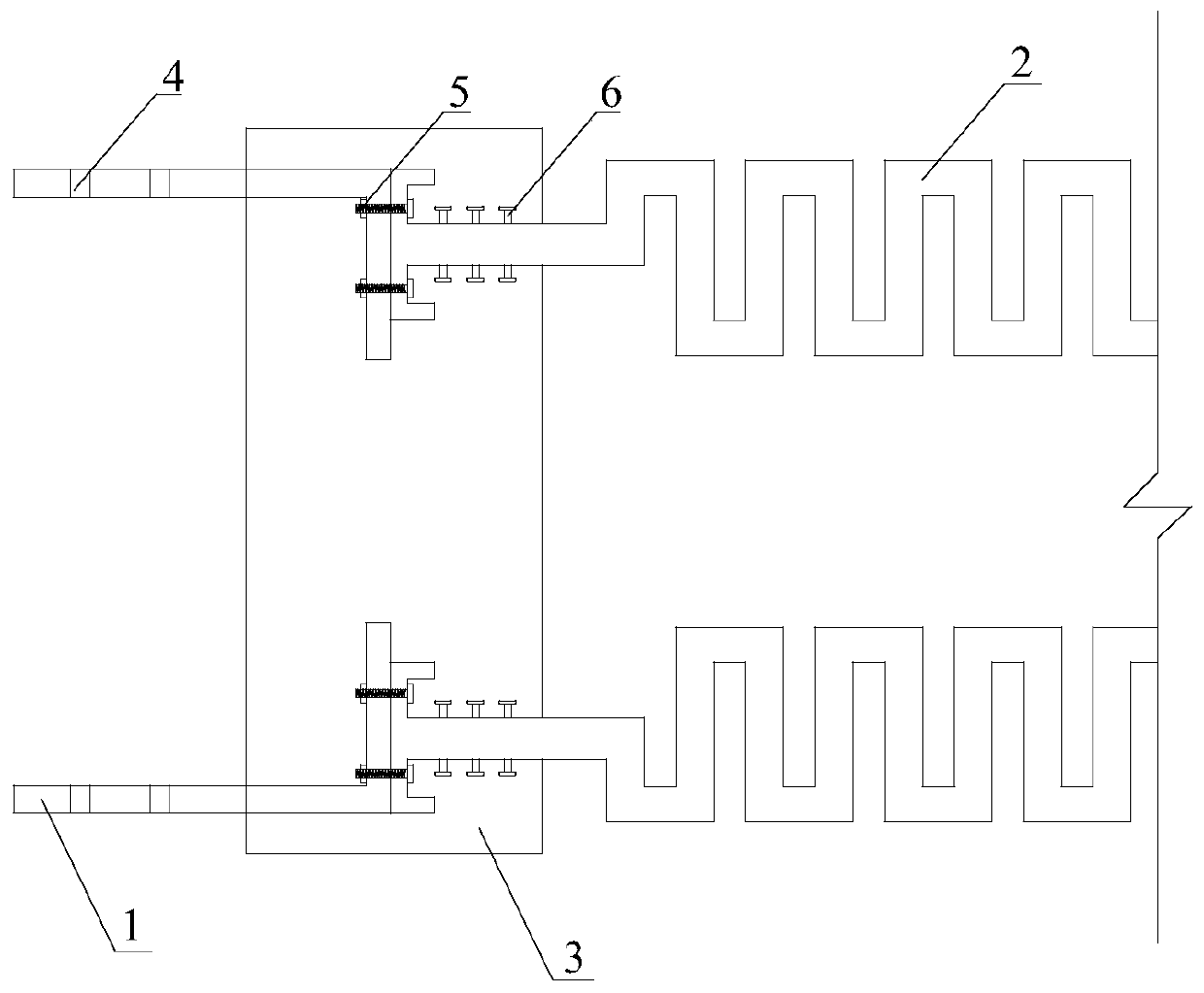

[0034] Such as Figure 1-3 As shown, an assembled corrugated steel plate shear wall structure includes a corrugated steel plate shear wall 2, an end reinforced concrete connection block 3, and an L-shaped bolt steel plate connector 1; the shear wall structure consists of two Composed of corrugated steel plates, the two ends of the two corrugated steel plates are T-shaped, and shear keys 6 are arranged on both sides of the ends;

[0035] In this example, both ends of the corrugated steel plate are provided with shear keys on both sides, and the embedded length thereof is 1 / 2 to 3 / 5 times the width of the concrete connecting block. The shear keys are arranged in a matrix on the surface of both ends of the steel plate, wherein they are evenly arranged at intervals of 10-20 cm along the vertical direction of the wall, and evenly distributed at i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com