Shipborne instrument impact resistant device combined with shape memory alloy and magnetorheological fluid

A technology of memory alloy and magnetorheological fluid, which is applied in the field of ships, can solve the problems of insufficient application of solid-like properties, single application principle of protection technology, and rapid development of difficult-to-breakthrough properties, so as to facilitate long-term storage, reduce utilization rate, Sensitivity, non-toxic, odorless and non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further describe the present invention below in conjunction with accompanying drawing:

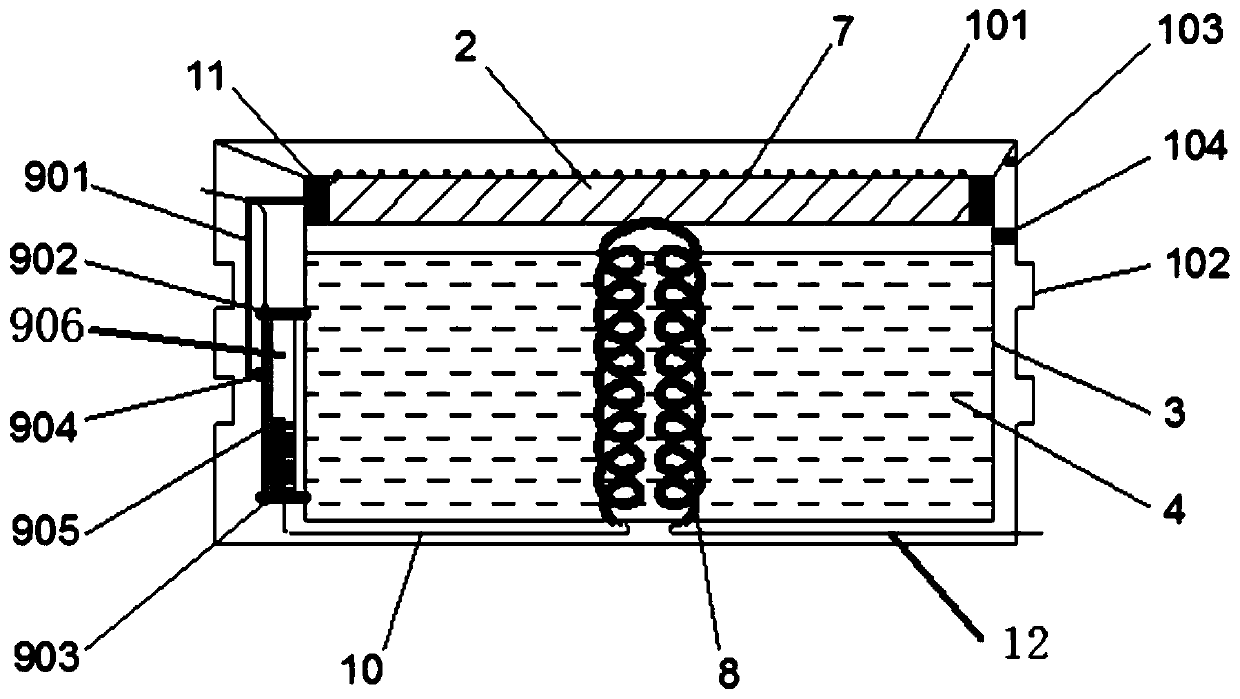

[0018] Such as figure 1 , a shipboard instrument anti-shock device composed of shape memory alloy and magnetorheological fluid, including an electromagnetic control module and a device impedance module;

[0019] Device impedance module, including supporting plate 2, magnetic isolation sleeve 3, magnetorheological fluid base fluid 4, filter membrane 6, magnetic particles 7, shape memory alloy spring 8, first wire 10, sealing ring 11, second wire 12 and a shape memory alloy shell 101;

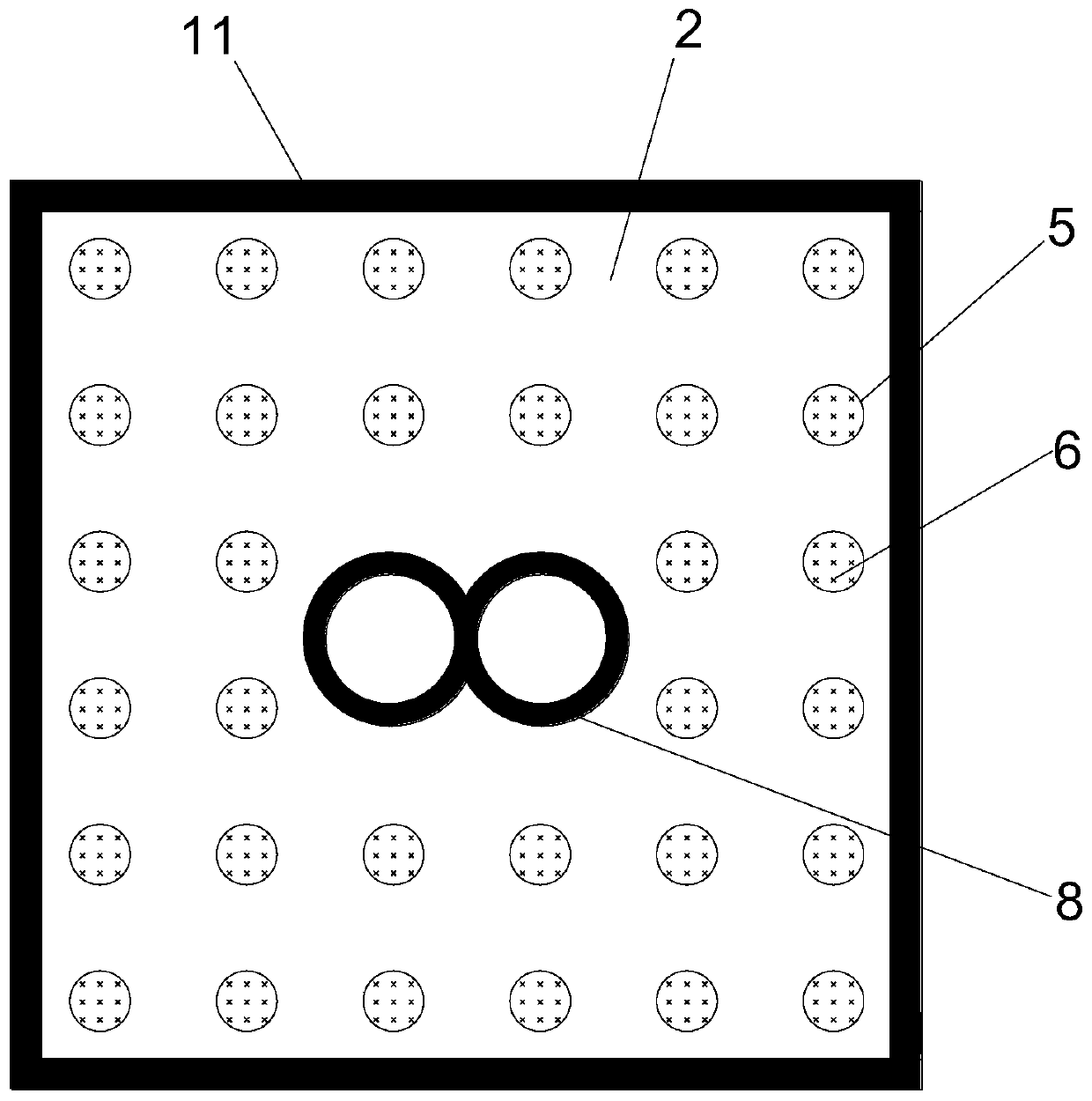

[0020] The magnetic isolation sleeve 3 is fixed in the shape memory alloy shell 101, the outer surface of the shape memory alloy shell 101 has a unit assembly interface 102, and the shape memory alloy shell 101 is provided with a placement cavity channel 103 and a working cavity channel 104; as figure 2 , the four sides of the supporting plate 2 are equipped with sealing rings 11, the sealing rings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com