Shield synchronous grouting construction technology

A technology of simultaneous grouting and construction technology, applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of short use time of grouting, inaccurate feeding, insufficient grouting efficiency, etc., and achieve easy surface deformation and settlement. Control, high shear yield strength, guaranteed workability and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Taking the synchronous grouting process of the shield construction of the subway tunnel as an example, the tunnel uses two earth pressure balance shields for excavation construction, the shield diameter is 6340mm, the lining is made of prefabricated reinforced concrete segments, the lining outer diameter is 6200mm, and the inner diameter is 5500mm. The buried depth of the tunnel is more than 14m, and the excavated soil layer is mainly saturated cohesive soil.

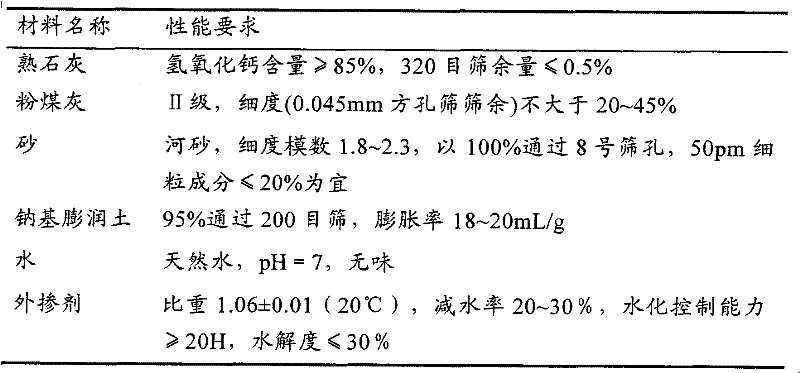

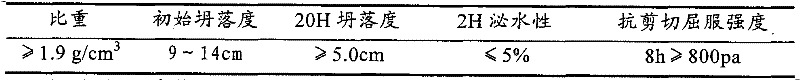

[0029] The single slurry of this embodiment includes 55% sand, 18% fly ash, 4.5% slaked lime, 2.8% sodium bentonite, 0.2% polycarboxylate superplasticizer and 19.5% water, each The performance requirements of grouting materials are shown in Table 1.

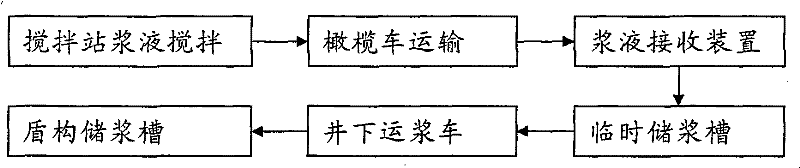

[0030] Step A) After the slurry feeding system in the mixing station receives the instructions of the control system, it weighs bentonite, fly ash, slaked lime, 2 / 3 water, sand, external admixture, and 1 / 3 water in sequence according to the above proportions, and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sand content | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com