Grinding wheel grinding sound emission monitoring device

A monitoring device and acoustic emission technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of signal coolant flow and pressure interference, poor versatility, and changing the structure of the grinding wheel, etc., to achieve Eliminate contact surface gaps, facilitate installation, and reduce reflection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

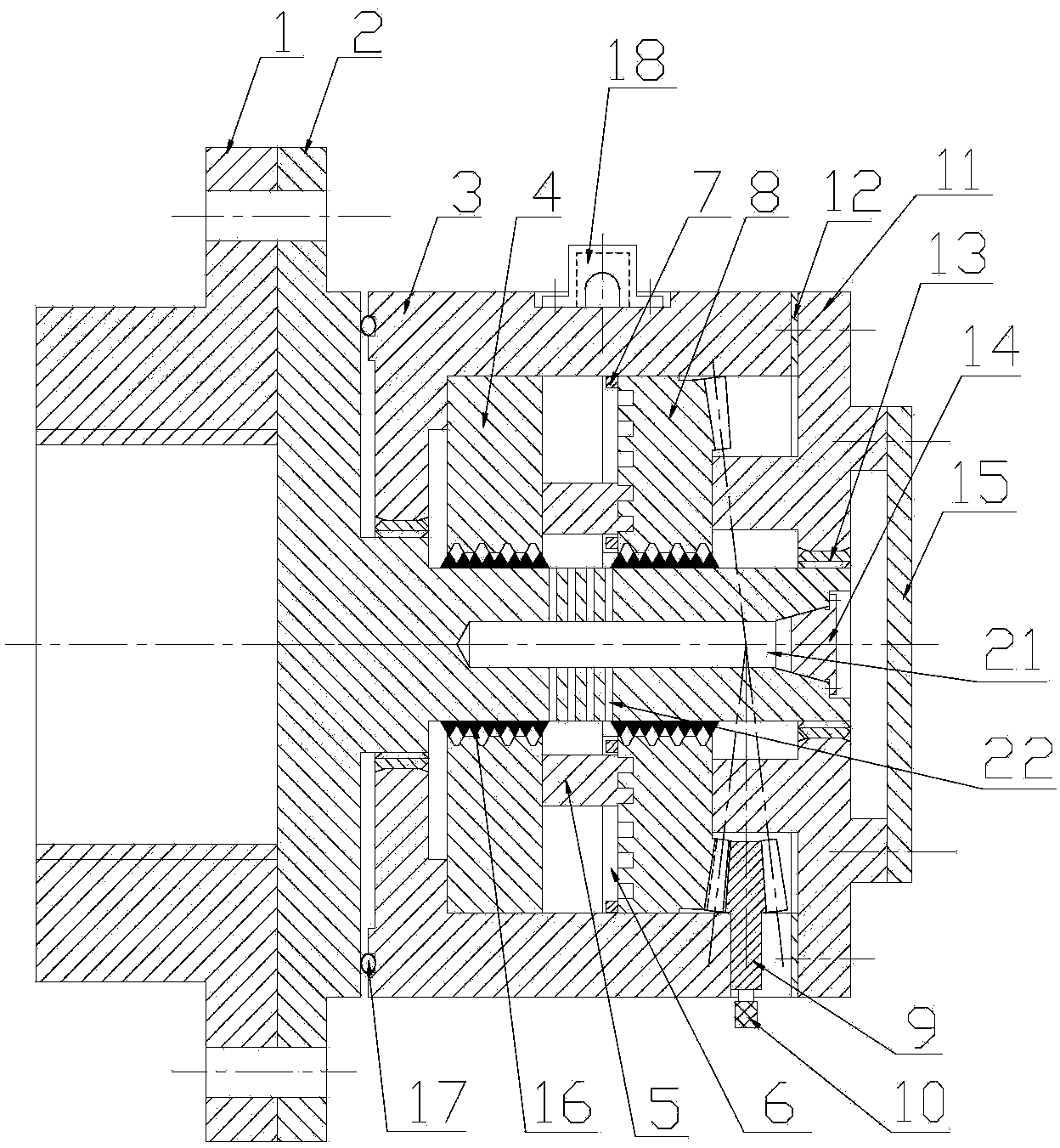

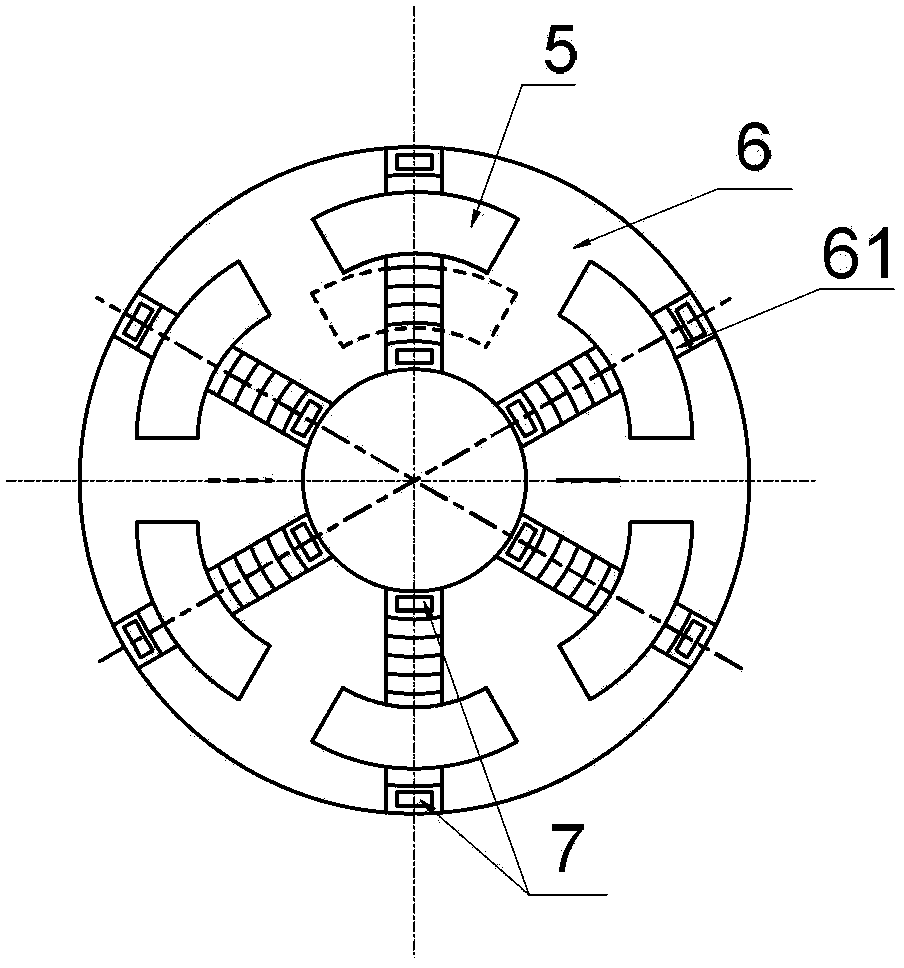

[0022] see figure 1 and 2 , the embodiment of the present invention is provided with a locking flange 1, a magnetic shaft 2, a housing 3, an annular magnetic pole 4, 6 permanent magnet blocks 5, a magnetic slide disc 6, a limit block 7, an annular conical magnetic pole 8, a cone Gear 9, handle 10, retaining ring 11, plug 14, end cap 15, magnetorheological fluid 16, acoustic emission sensor seat 18, acoustic emission sensor (not shown in the figure) and detection circuit (not shown in the figure).

[0023] The locking flange 1 is locked with the external grinding wheel. The left end of the magnetic rotating shaft 2 is connected with the locking flange 1. The magnetic rotating shaft 2 is provided with a hollow hole 21. The opening end of the hollow hole 21 is provided with a plug 14. The hollow hole 21 is filled with magnetorheological fluid. The hollow hole 21 is connected to the outer surface of the magnetic rotating shaft 2. It communicates with four radial holes 22 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com