Heating furnace mixed coal gas and natural gas burning switching device, and heating furnace mixed coal gas and natural gas burning switching method

A technology of mixing gas and combustion switching, which is applied in combustion methods, gas fuel burners, burners, etc., can solve the problems of natural gas burners being easily burned out, and achieve the effect of solving the shortage of blast furnace gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

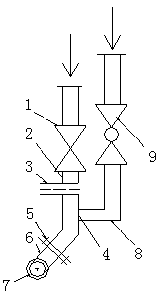

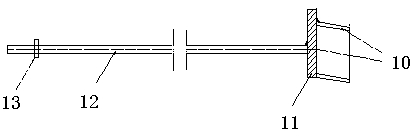

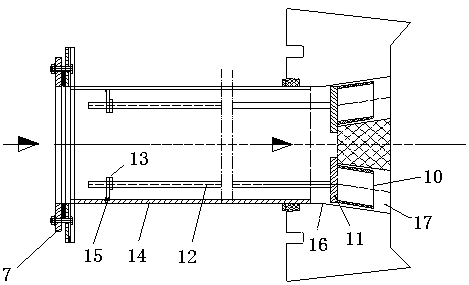

[0030] The present invention includes two parts: the pipeline transformation part before the burner and the inner transformation part of the core tube of the burner. The renovation of the pipeline before the burner adds a natural gas branch pipe and installs a switching device on the straight pipeline before the burner for switching between mixed gas and natural gas; the renovation inside the burner core tube is to adjust the nozzle area of the burner brick.

[0031] The mixed gas and natural gas combustion switching device of the heating furnace of the present invention consists of a natural gas branch pipe, a ball valve 9, a butterfly valve 1 in front of the burner, a manual blind plate 3, a quick-connect flange 5, a short tube 6 in front of the burner and a burner nozzle plugging device composition.

[0032] figure 1 It shows that it adds a natural gas branch pipe 8, the front end of the natural gas branch pipe 8 is connected with the gas branch pipe 2, a ball valve 9 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com