Method for electrically regenerating H type cation bed failure cation exchange resin through bipolar membrane method

A cation exchange and bipolar membrane technology, applied in ion exchange, ion exchange regeneration, ion exchange bed cleaning/flushing, etc., can solve the pollution of waste acid and alkali liquid discharge, low utilization rate of acid and alkali, poor working conditions, etc. problem, to achieve the effect of improving the working conditions of workers, convenient regeneration operation, and favorable promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

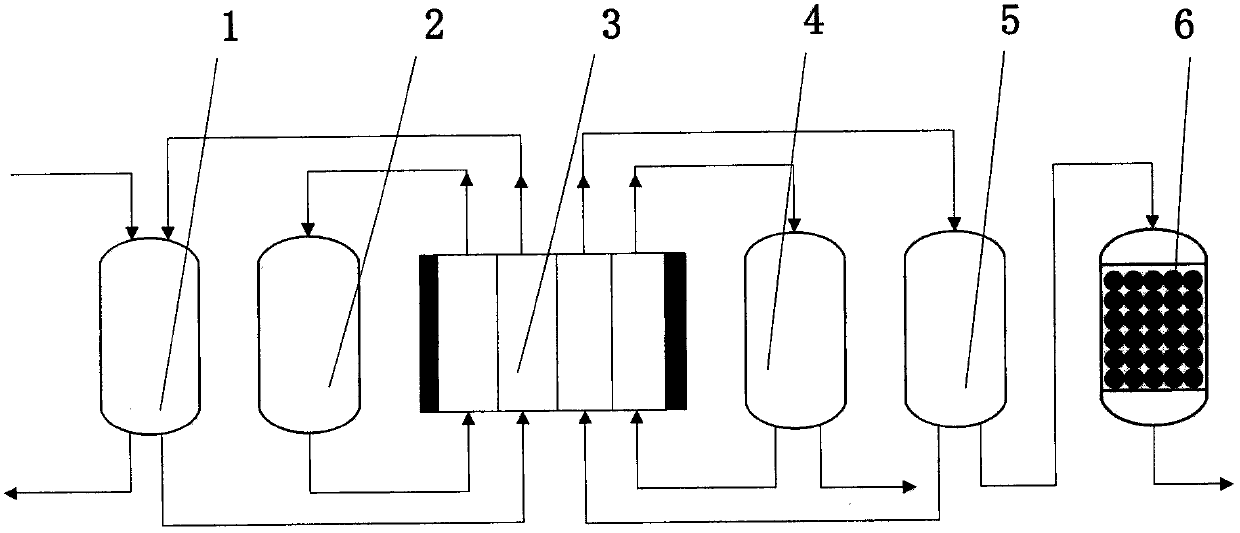

[0039] figure 1 It is a schematic diagram of the appearance of the method of electrically regenerating the H-type cation bed spent cation exchange resin by bipolar membrane method during downstream regeneration.

[0040] A method for electrically regenerating H-type cation bed invalid cation exchange resin by bipolar membrane method, the method comprises the following steps:

[0041] (1) Preparation of dilute brine: Before regeneration of the H-type positive bed, dilute brine should be prepared. Dilute brine is made by adding salt to pure water. The salt concentration should be adjusted to the set value. brine, stored in dilute brine tanks;

[0042] (2) Preparation of dilute acid regeneration solution: when the H-type cation bed fails and is disassembled, the bipolar membrane electrodialyzer is started, and under the action of a direct current electric field, the bipolar membrane electrodialyzer ionizes water into H + and OH - Ions, they are respectively combined with the s...

Embodiment 2

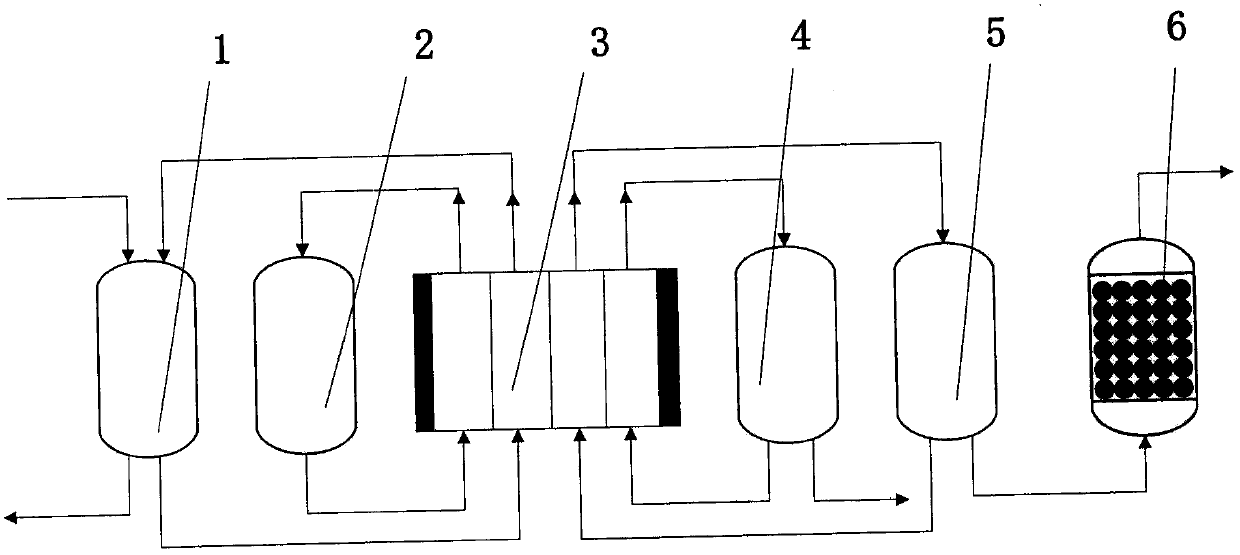

[0050] image 3 It is a schematic diagram of the appearance of the method of electrically regenerating H-type cation bed invalid cation exchange resin during countercurrent regeneration.

[0051] The method of bipolar membrane electrical regeneration of spent cation exchange resin in the H-type cation bed during countercurrent regeneration is roughly the same as that during downstream regeneration.

[0052] Countercurrent regeneration means that the flow direction of the regeneration liquid in the H-type cation-bed ion exchange tank is from bottom to top and the flow direction of the liquid to be treated is opposite from top to bottom during operation, that is, the two fluid directions are countercurrent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com