A surfacing repair method and system for weld repair of stainless steel branch pipes

A repair method and repair system technology, applied in the direction of welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as the surfacing welding repair of branch pipe welds that has not been realized, the shape of the saddle-shaped transition area is complicated, and the repair method cannot be effectively implemented. Achieve the effect of improving the state and distribution, reducing the residence time, and satisfying the weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Automatic pulse tungsten inert gas shielded welding (GTAW) is one of the methods with better welding quality in gas shielded arc welding in the world. During welding, the welding wire is fed by the wire feeding mechanism, and the welding torch performs automatic arc voltage feedback according to the set trajectory. For welding, the inert shielding gas is continuously sprayed from the nozzle of the welding torch, forming a gas shield around the molten pool to isolate the air. Compared with manual electrode arc welding (SMAW) commonly used in nuclear power engineering, automatic pulsed tungsten inert gas shielded welding (GTAW) can more accurately control welding heat input, improve weld formation, and improve weld quality. It is widely used in In the field of surfacing welding, especially the welding of thin-walled parts. Therefore, the present invention introduces automatic pulse tungsten inert gas shielded welding (GTAW) into the surfacing repair of stainless steel bra...

Embodiment 2

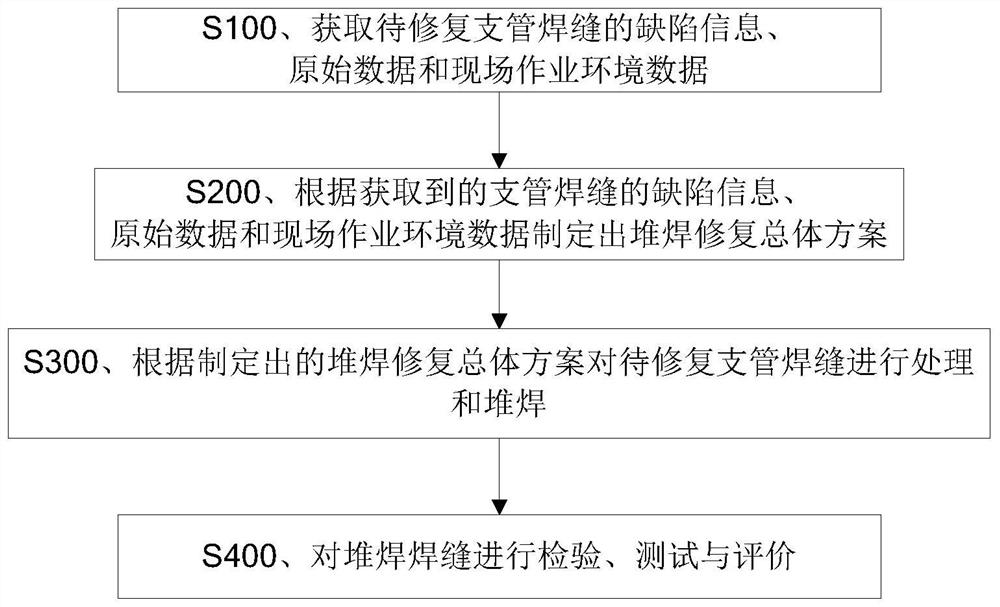

[0083] An embodiment of the present invention provides a surfacing repair system for weld maintenance of stainless steel branch pipes, see Figure 13 , is a system structure diagram of Embodiment 2 of the present invention, the system includes:

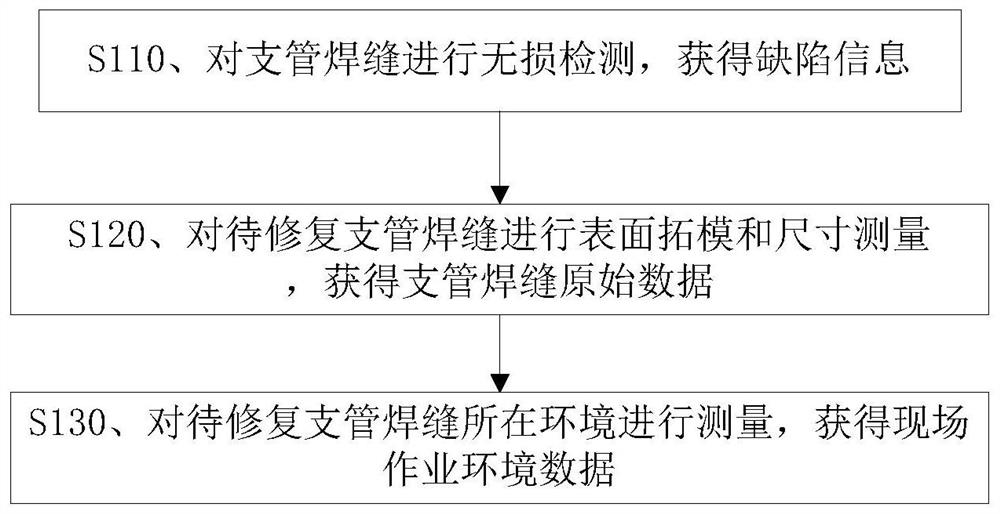

[0084] An information acquisition module 100, configured to acquire defect information, original data and on-site operating environment data of the weld seam of the branch pipe to be repaired;

[0085] The repair plan formulation module 200, connected to the information acquisition module 100, is used to formulate an overall repair plan for surfacing welding according to the obtained defect information of branch pipe welds, original data and field operation environment data;

[0086] The overlay welding overall implementation module 300 is connected to the repair plan formulation module 200, and is used to process and overlay welds of the branch pipes to be repaired according to the formulated overlay repair overall plan;

[0087] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com