Wafer edge chamfering machining method of quartz crystal resonator

A technology for quartz crystals and quartz wafers, which is applied in the field of beveling processing where the edge thickness and contour shape change. It can solve the problems of complex process, poor processing accuracy, and poor controllability, and achieve simple process, easy modification, and flexible beveling processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

[0022] A plate chamfering processing method of a quartz crystal resonator, using a laser with sufficient intensity to irradiate a quartz wafer, so as to realize the chamfering processing of wafer thickness reduction and contour shape change, the specific steps are:

[0023] a. the edge portion to be processed of the quartz wafer is divided into 6 strip-shaped regions to be processed;

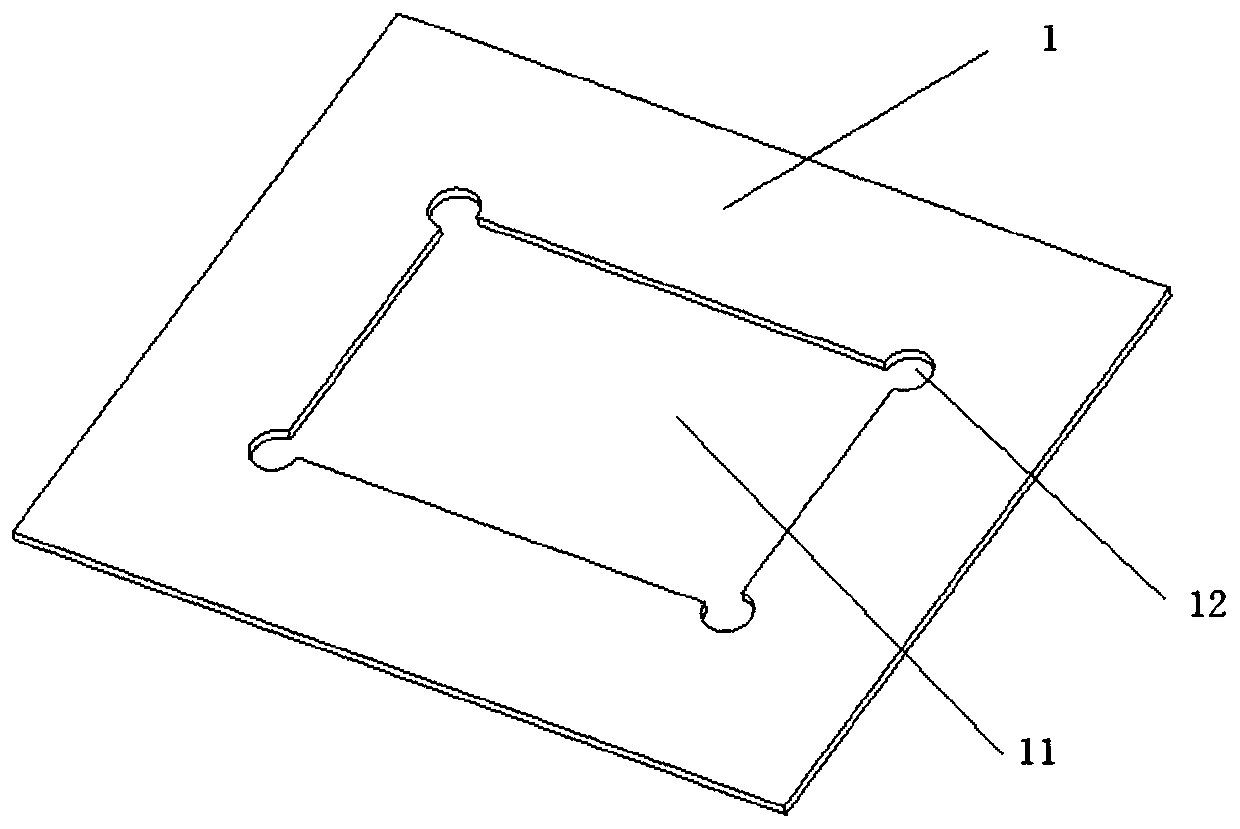

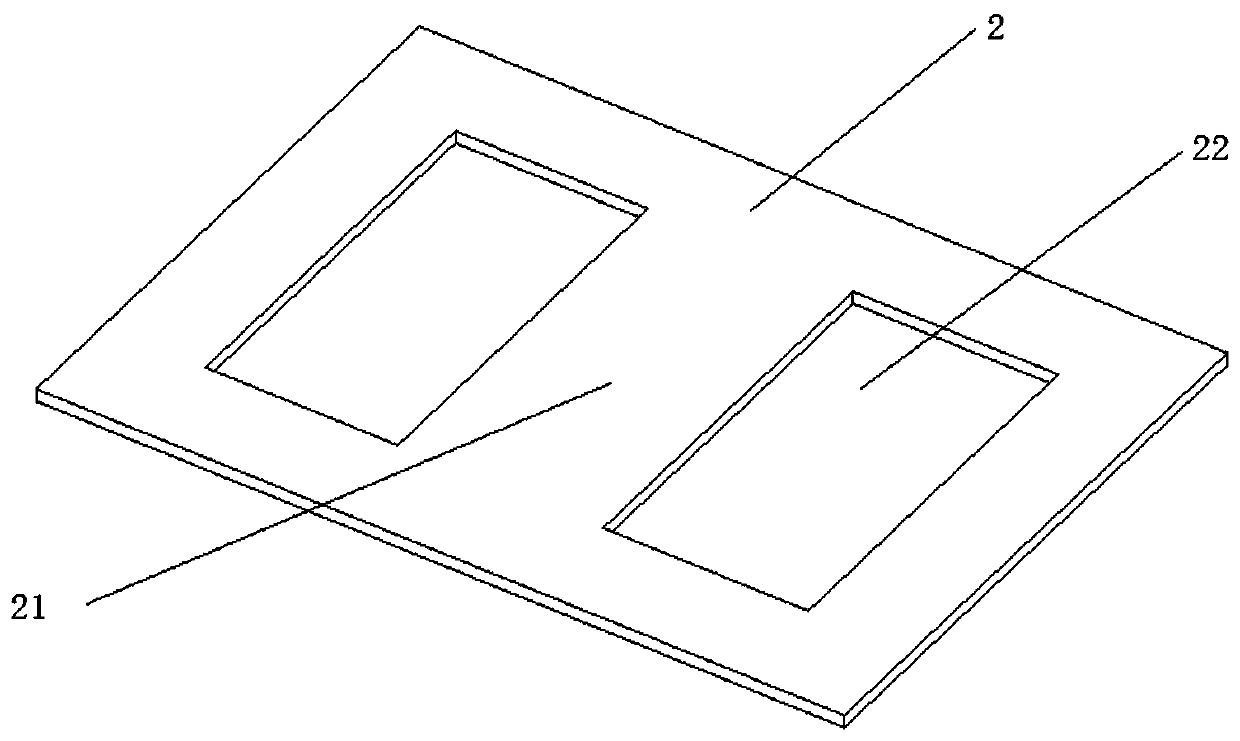

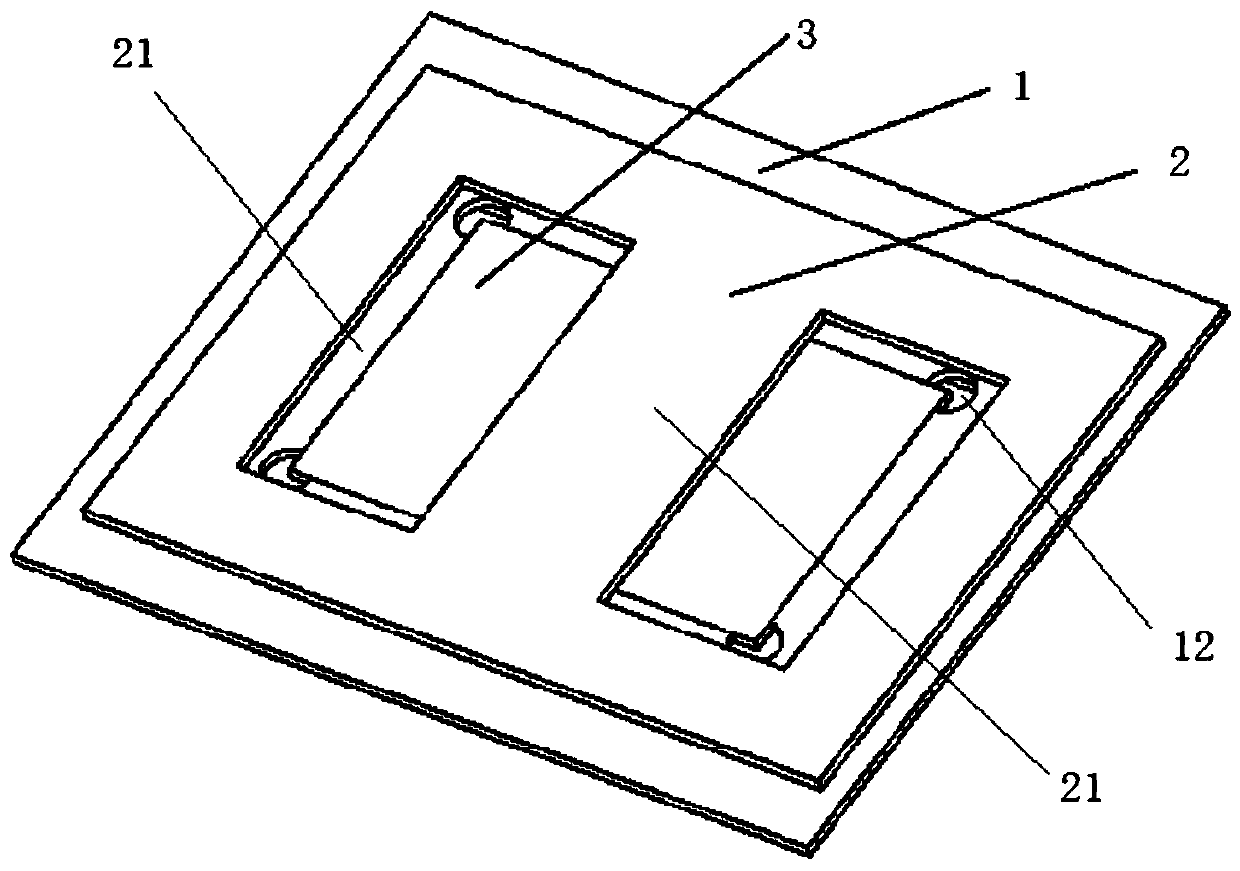

[0024] b. Place the quartz wafer on the special fixture. The special fixture includes a fixed plate 1 in the middle and two splints 2. The fixed plate 1 is provided with a transparent fixed cavity 11, and the four corners of the fixed cavity 11 are provided with circular protective holes. 12. The splint 2 is provided with a bead 21, and the two sides of the bead 21 are provided with processing holes 22. The quartz wafer 3 is embedded in the fixed cavity 11. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com